PVC Insulated Control Cable 450/750V (PVC Sheath, Armoring)

PVC Insulated Control Cable 450/750V (PVC Sheath, Armoring)

This PVC insulated control cable is manufactured in compliance with the GB/T9330-2008 standard. It is mainly applied to the control and protection of rated voltages up to 450/750V.

Operating characteristics

1. Rated power-frequency voltage U0/U: 450/750V

2. Maximum operating temperature: 70℃

3. The ambient temperature should be no less than 0℃ during installation.

4. Bend radius: no less than 6 times the cable diameter for non-armored and non-sheathed cable, no less than 12 times the cable diameters for armored and copper belt sheathed cable.

Cable Type

Model | Name | Application |

KVV | Copper conductor PVC insulated, PVC sheathed control cable | It can be laid in tunnels, cable trenches, indoors, pipelines, bridges and other fixed installation applications. |

KVV22 | Copper conductor PVC insulated, PVC sheathed steel belt armored control cable | It can be laid in tunnels, cable trenches and indoors. This model can bear a significant amount of external mechanical force |

KVVR | Copper conductor, PVC insulated, PVC sheathed flexible control cable. | It is suitable for laying in indoors and any flexible installation applications. |

Production Range

Model | Rated Voltage (V) | Nominal cross-section of conductor (mm2) | ||||||

0.75 | 1.0 | 1.5 | 2.5 | 4 | 6 | 10 | ||

Core number | ||||||||

KVV | 450/750 | 2-61 | 2-14 | 2-10 | ||||

KVV22 | 450/750V | 7-16 | 4-6 | 4-14 | 4-10 | |||

KVVR | 4-61 | — | — | |||||

4-61 | 4-48 | — | — | |||||

Note: Recommended core number: 2, 3, 4, 7, 8, 10, 12, 14, 16, 19, 24, 27, 30, 37, 44, and 48. Non-standard products can also be produced according to customers’ specific needs.

Data Sheet

No. | Test Conditions | Unit | Rated cable voltage 450/750V |

1 | Finished product voltage test | ||

1.1 | Length of sample | m | Length of delivered products |

1.2 | Temperature test | Ambient temperature | |

1.3 | Voltage test | V | 3000 |

1.4 | High-voltage holding time | min | 5 |

2 | Insulation wire core voltage test | ||

2.1 | Minim length for testing sample | m | 5 |

2.2 | Time for soaking in water | h | 1 |

2.3 | Water temperature | ℃ | 20±5 |

2.4 | Voltage test | ||

2.4.1 | Insulation thickness≤0.6mm | V | 2000 |

2.4.2 | Insulation thickness>0.6mm | V | 2500 |

2.5 | High-voltage holding time | min | 5 |

As a China-based, professional PVC insulated control cable manufacturer and supplier in China, we at Huanya have been committed to producing high quality XLPE core prefabricated branch cable, high temperature resistant cable and high temperature to customers since our establishment in 1990. Through over 2 decades of experience and tireless efforts, we are now able to offer customers superior products at economical prices. We welcome you to contact us for more information about our control cables.

Links:https://www.globefindpro.com/products/97731.html

-

Overhead Cable (Aluminum Strands)

Overhead Cable (Aluminum Strands)

-

Control Cable

Control Cable

-

XLPE Insulated PVC Power Cable 3.6/6kV-26/35kV

XLPE Insulated PVC Power Cable 3.6/6kV-26/35kV

-

Overhead Insulated Power Cable

Overhead Insulated Power Cable

-

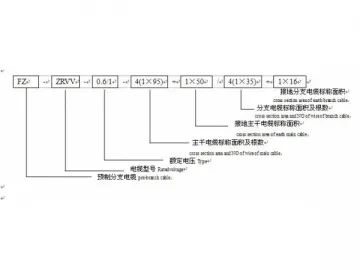

Single Core Prefabricated Branch Cable 0.6/1kV (PVC Insulated Sheath)

Single Core Prefabricated Branch Cable 0.6/1kV (PVC Insulated Sheath)

-

Cloth Covered Wire

Cloth Covered Wire

-

PVC Insulated Cable (PVC Sheath Cable 0.6/1kV)

PVC Insulated Cable (PVC Sheath Cable 0.6/1kV)

-

BS Standard Rails

BS Standard Rails

-

Chinese Standard Rails

Chinese Standard Rails

-

Computer Cable

Computer Cable

-

GB Standard Light Rails

GB Standard Light Rails

-

Continuous Pasteurizing Tunnel Cooler

Continuous Pasteurizing Tunnel Cooler