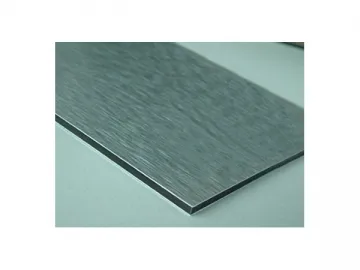

Brush Aluminium Composite Panel

Brush Aluminium Composite Panel

The surface of the aluminumcomposite panel undergoes brush treatment and comes with a protective coatingthat can be removed. We have a Silver Brush and Gold Brush aluminum composite panel.We are a professional manufacturer of aluminum composite panels and service allkinds of surface treatment aluminum composite panels, such as marble, wood,nano, mirror finished, etc.

Description of the Brush Aluminium Composite Panel

Dimensions

Standard size: 1220mm x 2440mm and 1250mm x 2440mm

Accepted thickness: 3mm, 4mm, 5mm,6mm

Accepted width: Max. 1580mm

Such as: 1220mm, 1250mm, 1500mm, 1575mm

Accepted length:According to buyer's requirement

Accepted aluminumsheet thickness: 0.15~0.5mm

Such as:0.15mm, 0.21mm, 0.27mm,0.3mm, 0.35mm, 0.4mm, 0.45mm,0.5mm

Applications

1. The brush aluminum composite panel can beused in galleries, exhibitions, saloons, stores, offices, banks, hotels,restaurants, apartments, etc.

2. Other kinds of buildings: It is ideal asdecorative material for the outer-wall and inner-wall of buildings.

3. The brush aluminum compositepanel can be used for kitchen cabinets, billboards, signboards, tunnels andsubway interiors, ceilings, eaves, balconies, partitions and interiordecorations, telephone booths, vehicle bodies, and industrial usages.

4. It can be used for there-decoration of old buildings.

Material

a) Top:Aluminum alloy sheet coated with fluoro-carbon resin (PVDF) and polyester resin(PE) roasting painting.

b) Core: Non-toxic polyethyleneor fireproof material

c) Back: Aluminum alloy sheetcoated with polyester resin painting

d) Surface finish: PVDF/PE resin,brush finish, mirror finish, wooden faced, nano painting, etc.

e) Surfacecoating thickness: 30 um 70% KYNAR PVDF

Quality

1) Undernatural climate, the film coating will not flake, and there will be no rubbles,vestige or pulverization.

2) Undercommon environment there will be no flake and no rubbles.

3) Undercommon temperatures and radiation, no color deferent.

4) Accordingto the international test standard, all the tested items are satisfied withhigh-class.

5) Ourproducts with PVDF coating are produced under GB/T17748-1999 with 70% PVDF.Under a normal environment, we can guaranteeour product for 15~20 years. Our FR products are good at fireproof andthe FR grade is A2, B1 (according to the standard Q B8624).

Links:https://www.globefindpro.com/products/97998.html

-

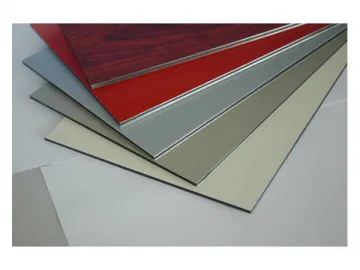

Nano Aluminum Composite Panel

Nano Aluminum Composite Panel

-

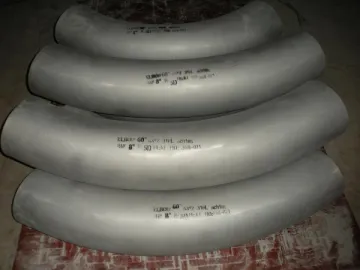

Pipe Bend

Pipe Bend

-

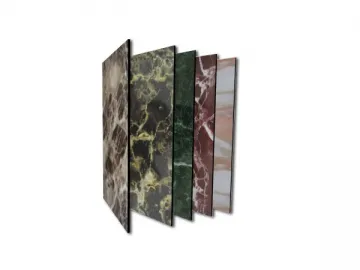

Marble Aluminum Composite Panel

Marble Aluminum Composite Panel

-

ERW Steel Pipe

ERW Steel Pipe

-

PVDF Coating Aluminium Composite Panel

PVDF Coating Aluminium Composite Panel

-

Pipe Cap

Pipe Cap

-

Fireproof Aluminium Composite Panel, B Grade

Fireproof Aluminium Composite Panel, B Grade

-

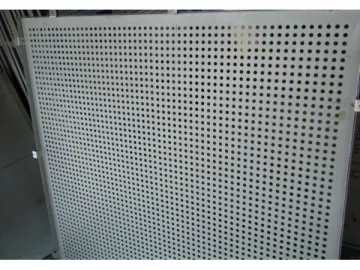

Perforated Aluminum Composite Panel

Perforated Aluminum Composite Panel

-

Mirror Aluminium Composite Panel

Mirror Aluminium Composite Panel

-

Weld Neck Flange

Weld Neck Flange

-

PE Coating Aluminium Composite Panel

PE Coating Aluminium Composite Panel

-

IBM Toner Chip

IBM Toner Chip