Double Direction Marble Cutting Machine

Double Direction Marble Cutting Machine

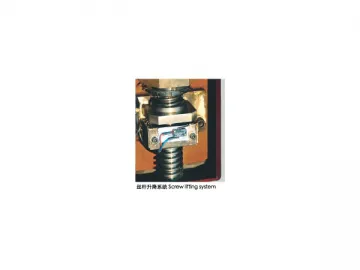

Thedouble direction marble cutting machine SQC-1600S/1800S/2000S uses a rotary encoder at the end ofthe lead screw (which drives the side beam) for precision slicing. Protectiondevices are used for lifting and side-beam transmission, which keep smoothcutting. Multi-slates cutting andhorizontal cutting are controlled by the central computer, which ensuresautomatic and accurate cutting, safety and reliability.

Note: the 360° rotating worktable can be selected if needed.

Technical Data of Double Direction Marble Cutting Machine

| Item | Unit | TYPE A | TYPE B |

| Max. blade diameter | mm | Φ 1 600/Φ1800/Φ2000 | |

| Max. vertical stroke | mm | 1150/1350 | |

| Max. worktable length | mm | 3400/3200/3000 | 4200/4000/3800 |

| Max. worktable width | mm | 2300 | |

| Saw blade diameter for horizontal cutting | mm | Φ400 | |

| Max. vertical stroke of main column for horizontal cutting | mm | 900/1000/1100 | |

| Power of main motor for horizontal cutting | kW | 11 | |

| Water consumption | m3/h | 10 | |

| Power of main motor | kW | 55/75/90 | |

| Total power | kW | 75/95/110 | |

| Dimension (LxWxH ) | mm | 6900/3800/4200 | 7800/3800/4200 |

| Weight | kg | 10000 | 10300 |

Accessories

1. Side-beam protection device

2. Hydraulic feed device

3. Rotary worktable (optional)

Termsof trade of Double Direction Marble Cutting Machine

Julun is a professional double direction marblecutting machine manufacturer in China.In addition, our company offers automatic special-shaped stone cutting machine,granite cutting machine, automatic granite polishing machine, and manual stonecalibrating machine, among others.

Links:https://www.globefindpro.com/products/98044.html

-

Stone Edge Chamfering Machine

Stone Edge Chamfering Machine

-

Tilt Marble Cutting Machine

Tilt Marble Cutting Machine

-

MR16 RGB LED Spotlight

MR16 RGB LED Spotlight

-

PAR38 High Brightness LED PAR Light 12*2W

PAR38 High Brightness LED PAR Light 12*2W

-

Remote LED Controller

Remote LED Controller

-

AR111 LED Spotlight 7*2W

AR111 LED Spotlight 7*2W

-

Block Stone Cutting Machine

Block Stone Cutting Machine

-

Tilt Stone Cutting Machine

Tilt Stone Cutting Machine

-

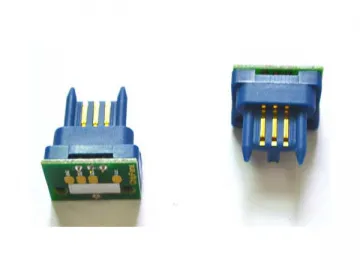

Sharp Toner Chip

Sharp Toner Chip

-

Stone Cutting Machine

Stone Cutting Machine

-

Double Direction Stone Cutting Machine

Double Direction Stone Cutting Machine

-

Automatic Granite Polishing Machine

Automatic Granite Polishing Machine