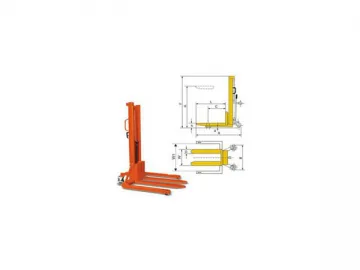

FE4P20/25/30/35 Electric Forklift Truck

FE4P series balance weight battery forklift truck is developed based on the design concept of modularization and serialization. It emphasizes on safety and practicality, and is simple in structure, easy to operate and maintain and is environmentally friendly.

Features

1. This electric forklift truck is designed with large arc streamlined red outward appearance, coated surface, and welded steel plate frame.

2. The steering axle and truck body are flexibly connected, thus reducing the impact and failure rate and prolonging the service life of the truck.

3. The split type enlarged working oil tank can not only reduce the thermal balance temperature of the system and prolong the service life of hydraulic components, but also facilitate the maintenance work.

4. The high visibility mast provides a broad vision for operator and thus contributes to the improvement of working efficiency.

5. This electric forklift truck is fitted with taillights, headlights and warning light, ensuring the safety during night work.

6. Its liquid crystal display is of high definition and self diagnosis function. The LCD can diagnose out the operation mistake and system failure and then display them out in the form of pictures or characters. Besides, it will warn or power down automatically when the battery power is low, to prevent over discharge.

7. High frequency MOSFET integrated controller is provided with regenerative braking and reverse braking functions, beneficial to energy recovery. Advanced separately excited control system can effectively prevent the truck from slipping down on ramp, thus ensuring safe running.

8. Adjustable steering wheel and seat enable operator to find his optimum driving position and help ease his tiredness caused by long time driving.

9. High performance accumulator and different configurations can satisfy you different needs.

10. Parallel connection drive system provides the truck with strong gradeability.

11. With minimum turning radius, this electric forklift truck can work in narrow space.

12. This electric forklift truck uses seat switch and emergency power off switch, in accordance with international standard The working motor will stop working automatically when the operator has been away from the seat beyond the set time, thus avoiding unnecessary power consumption. Besides, this forklift truck is fitted with seat belt and armrest to ensure the safety of operator.

13. The inclined cylinder is internally installed, which enlarges working place for operator, makes the truck aesthetic in appearance and makes it easier for the operator to get on or off the truck.

Parameters of FE4P20/25/30/35 series Electric Forklift Truck

| Characteristics | 1.1 | Manufacturer (abbreviation) | Hylifting | ||||

| 1.2 | Model | FE4R20 | FE4R25 | FE4R30 | FE4R35 | ||

| 1.3 | Drive mode: electricdrive, diesel fuel, gasoline,fuel gas, manual drive | Electric drive | |||||

| 1.4 | Operation mode | Sit-on type | |||||

| 1.5 | Rated carrying capacity | Q(kg) | 2000 | 2500 | 3000 | 3500 | |

| 1.6 | Load center distance | C(mm) | 500 | ||||

| 1.8 | Front overhang | X(mm) | 473 | 448 | 506 | ||

| 1.9 | Wheel base | Y(mm) | 1500 | 1680 | |||

| Weight | 2.1 | Dead weight includingaccumulator (see 6.5) | kg | 4000 | 4150 | 5050 | 5300 |

| 2.2 | Load per axle when full load, front/ rear | kg | 5400/600 | 5985/665 | 6980/1070 | 7580/1220 | |

| 2.3 | Load per axle when noload, front /rear | kg | 1600/2400 | 1660/2490 | 2260/2790 | 2360/2490 | |

| Wheel, truck body | 3.1 | Tyre: solid rubber tyre, high elastic rubber tyre,pneumatic tyre, PU tyrefront/rear | Pneumatic tyre/ pneumatic tyre | ||||

| 3.2 | Front wheel tyre size | 7.00-12-12PR | 28×9-15-12PR | ||||

| 3.3 | Rear wheel tyre size | 18×7-8-14PR | |||||

| 3.5 | Wheel quantity, front wheel/ rear wheel (×=driving wheel) | 2×/2 | |||||

| 3.6 | Wheel span, front wheel | b10(mm) | 960 | 1000 | |||

| 3.7 | Wheel span, rear wheel | b11(mm) | 950 | 990 | |||

| Basic dimension | 4.1 | Mast /fork carrier tiltangle, forward/ backward | a/ß(°) | 6/12 | |||

| 4.2 | Closed mast height | h1(mm) | 2010 | 2080 | 2180 | ||

| 4.3 | Free lifting height | h2(mm) | 140 | 145 | 150 | ||

| 4.4 | Lift height | h3(mm) | 3000 | ||||

| 4.5 | Extended mast height | h4(mm) | 4040 | 4255 | |||

| 4.7 | Overhead guard height | h6(mm) | 2110 | 2210 | |||

| 4.8 | Seat height | h7(mm) | 1058 | 1063 | |||

| 4.12 | Traction pin height | h10(mm) | 210 | ||||

| 4.19 | Total length | l1(mm) | 3433 | 3458 | 3673 | 3721 | |

| 4.2 | Truck body length excluding forks | l2(mm) | 2363 | 2388 | 2603 | ||

| 4.21 | Total width | b1(mm) | 1150 | 1225 | |||

| 4.22 | Fork size | s/e/l(mm) | 40×122×1070 | 45×125×1070 | 50×140×1070 | ||

| 4.23 | Fork carrier, according to ISO2328, grade/ type A, B | ISO 2A | |||||

| 4.24 | Fork carrier width | b3(mm) | 1040 | 1100 | |||

| 4.31 | Ground clearance under mast | m1(mm) | 100 | 137 | |||

| 4.32 | Wheel base center groundclearance | m2(mm) | 110 | 145 | |||

| 4.33 | Working aisle width, 1000×1200 pallet(1200 side placed across forks) | Ast(mm) | 3800 | 3828 | 3988 | 4032 | |

| 4.34 | Working aisle width, 800×1200 pallet(1200 side placed along forks) | Ast(mm) | 4000 | 4028 | 4188 | 4232 | |

| 4.35 | Turning radius | Wa(mm) | 2130 | 2155 | 2300 | 2326 | |

| Performance | 5.1 | Driving speed, full load/no load | Km/h | 11/12 | |||

| 5.2 | Lifting speed, full load/no load | mm/s | 260/400 | 250/390 | 240/360 | 230/350 | |

| 5.3 | Descending speed, fullload/ no load | mm/s | 500/500 | ||||

| 5.5 | Drawbar pull, full load/no load S260 minutes | N | 8500/6000 | 9000/6400 | 12000/9700 | 14000/10500 | |

| 5.8 | Gradeability, full load/ no load | % | 15/18 | 12/15 | 10/12 | 8/10 | |

| 5.1 | Service braking | Hydraulic brake | |||||

| Motor | 6.1 | Driving motor power(S260 minutes) | kW | 8 | 10 | ||

| 6.2 | Lifting motor power(S2 15%) | Kw | 10 | 12 | |||

| 6.3 | Accumulator, according toDIN43531/35/36A, B, C, no standard | DIN43535A | |||||

| 6.4 | Accumulator voltage/ rated capacity K5 | V/Ah | 48/600 | 80/560 | |||

| 6.5 | Accumulator weight | kg | 947 | 1450 | |||

| 6.6 | Accumulator size, Length/ Width/Height | mm | 975×466×780 | 1028×685×780 | |||

| Others | 8.1 | Drive control type | Direct current | ||||

| 8.2 | Working pressure for attachments | bar | 175 | ||||

| 8.3 | Oil mass for attachments | l/min | 36 | ||||

| 8.4 | Noise level in operator's ear, according to EN12053 | dB(A) | 70 | ||||

FEP20~30 Mast Table

| FEP20~30 Mast Table | ||||||||

| Mast forms | Lift height(mm) | Free lifting height (mm) | Closed mast height (mm) | Maximum extended height (mm) | Mast tilt angle (°) | |||

| FEP20/25/30/35 | FEP20/25 | FEP30 | FEP20/25 | FEP30 | FEP20/25 | FEP30 | FEP20/25/30 | |

| Two stage high visibility mast | 2000 | 140 | 145 | 1515 | 1570 | 2992 | 3255 | 6/12 |

| 2500 | 140 | 145 | 1775 | 1820 | 3492 | 3755 | 6/12 | |

| 3000 | 140 | 145 | 2005 | 2070 | 3992 | 4255 | 6/12 | |

| 3300 | 140 | 145 | 2175 | 2220 | 4292 | 4555 | 6/12 | |

| 3600 | 140 | 145 | 2350 | 2370 | 4592 | 4855 | 6/6 | |

| 4000 | 140 | 145 | 2575 | 2620 | 4992 | 5255 | 6/6 *6/12 | |

| 4300 | 140 | 145 | 2725 | 2765 | 5242 | 5505 | 6/6 *6/12 | |

| 4500 | 140 | 145 | 2825 | 2870 | 5492 | 5755 | 6/6 *6/12 | |

| 5000 | 140 | 145 | 3125 | 3170 | 5992 | 6255 | 6/6 *6/6 | |

| 5500 | 140 | 145 | 3375 | 3420 | 6492 | 6755 | 3/6 *3/6 | |

| 6000 | 140 | 145 | 3625 | 3670 | 6992 | 7255 | 3/6 *3/6 | |

| Two stage free lifting mast | 2000 | 1000 | 1000 | 1515 | 1570 | 2992 | 3255 | 6/12 |

| 2500 | 1200 | 1200 | 1775 | 1820 | 3492 | 3755 | 6/12 | |

| 3000 | 1500 | 1500 | 2005 | 2070 | 3992 | 4255 | 6/12 | |

| 3300 | 1700 | 1700 | 2175 | 2220 | 4292 | 4555 | 6/12 | |

| 3600 | 1295 | 1295 | 2350 | 2370 | 4592 | 4855 | 6/6 | |

| 4000 | 2000 | 2000 | 2575 | 2620 | 4992 | 5255 | 6/6 *6/12 | |

| 4300 | 2200 | 2200 | 2752 | 2765 | 5242 | 5505 | 6/6 *6/12 | |

| 4500 | 2250 | 2250 | 2825 | 2870 | 5492 | 5755 | 6/6 *6/12 | |

| 5000 | 2500 | 2500 | 3125 | 3170 | 5992 | 6255 | 6/6 *6/6 | |

| 5500 | 2750 | 2750 | 3375 | 3420 | 6492 | 6755 | 3/6 *3/6 | |

| 6000 | 3000 | 3000 | 3625 | 3670 | 6992 | 7255 | 3/6 *3/6 | |

| Three stage free lifting mast | 3600 | 1260 | 1260 | 1800 | 1950 | 4592 | 4855 | 6/6 *6/6 |

| 4000 | 1300 | 1300 | 1910 | 2070 | 4992 | 5255 | 6/6 *6/6 | |

| 4300 | 1400 | 1400 | 2010 | 2050 | 5242 | 5505 | 6/6 *6/6 | |

| 4500 | 1500 | 1500 | 2080 | 2135 | 5492 | 5755 | 6/6 *6/6 | |

| 4800 | 1650 | 1650 | 2180 | 2330 | 5792 | 6055 | 6/6 *6/6 | |

| 5000 | 1700 | 1700 | 2230 | 2450 | 5992 | 6255 | 6/6 *6/6 | |

| 5500 | 1800 | 1800 | 2445 | 2615 | 6492 | 6755 | 3/6 *3/6 | |

| 6000 | 2000 | 2000 | 2660 | 2780 | 6992 | 7255 | 3/6 *3/6 | |

FEP20~30 Mast Table

| Mast | Load (kg)c=500mm | ||

| forms | Without side shifting | ||

| FEP20 | FEP25 | FEP30 | |

| Two stage high visibility mast | 2000 | 2500 | 3000 |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 1850*2000 | 2100*2500 | 2750*3000 | |

| 1700*1900 | 2000*2400 | 2550*3000 | |

| 1400*1700 | 1600*2200 | 2100*2800 | |

| 1050*1500 | 1200*1700 | 1650*2300 | |

| 700*1300 | 800*1400 | 1200*1900 | |

| Two stage free lifting type mast | 2000 | 2500 | 3000 |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 2000 | 2500 | 3000 | |

| 1850*2000 | 2100*2500 | 2750*3000 | |

| 1700*1900 | 2000*2400 | 2550*3000 | |

| 1400*1700 | 1600*2200 | 2100*2800 | |

| 1050*1500 | 1200*1700 | 1650*2300 | |

| 700*1300 | 800*1400 | 1200*1900 | |

| Three stage free lifting type mast | 2000 | 2500 | 3000 |

| 1900 | 2300 | 2850 | |

| 1700*2000 | 2000*2500 | 2650*3000 | |

| 1600*1900 | 1900*2400 | 2450*3000 | |

| 1400*1800 | 1600*2300 | 2200*2900 | |

| 1300*1700 | 1500*2200 | 2000*2800 | |

| 1000*1500 | 1150*1700 | 1600*2300 | |

| 700*1300 | 800*1400 | 1200*1900 | |

As a professional electric forklift truck manufacturer and supplier in China, we have many years of experience in producing industrial lifting equipment, hydraulic machinery and know well how to manufacture high quality products at low cost.

We welcome you to contact us for any information you need. OEM service is also available, upon request.

Links:https://www.globefindpro.com/products/98263.html