XH718 Vertical Machining Center

XH718 Vertical Machining Center

Features

1. XH718 vertical machining center adopts a high-speed, high-precisionspindle unit.

2. The machine base is made of high-strengthcast iron which has undergone aging treatment, ensuring stable accuracy.

3. The base uses four guide rails of super-large rectangular structure, whichresults in high rigidity.

4. X, Y, Z axesadopt widened rectangular guideways which have been preciselyground.

5. Smooth movement of the spindle box is ensured.

6. X, Y and Z axis use super-big, high-precision and high-intensity ball screw.The screw and servo motor are connected using flexible coupling, so as toensure machine positioning accuracy.

7. The screw of pre-tension structure greatly reduces the influenceof thermal variations on the positioning accuracy.

8. The guide screw of pre-stretch structure ensures high positioningaccuracy by minimizing thermal expansion effect.

9. The vertical machiningcenter uses an automatic lubrication system.

Main Accessories

| Standard Accessories | Optional Accessories |

| FANUC 0i mate CNC system | FANUC 0i MD/Siemens 802D/HNC-22M CNC system |

| Round plate type A.T.C with 24 tools capacity | The 4th-axis |

| Fully enclosed splash guard | Auto chip removal device |

| Separated type electronic handwheel | Oil cooling spindle |

| Standard exterior RS232 interface |

Main Technical Parameters of XH718 Vertical Machining Center

| Item | Unit | Technical parameters |

| X-axis travel | mm | 1500 |

| Y-axis travel | mm | 800 |

| Z-axis travel | mm | 700 |

| Distance from spindle nose to table | mm | 150-850 |

| Distance from spindle center to column guide-way face | mm | 850 |

| High speed feed ing of X,Y,Z axis | mm/min | 15000/15000/12000 |

| Feed ing speed | mm/min | 1-5000 |

| Table size | mm | 800×1700 |

| Max. loading capacity of table | kg | 1500 |

| T-slot NO./width/distance of table | 5/22/15 | |

| Max. speed of spindle | r/min | 80-6000 |

| Main motor rated power | kw | 11/15 |

| Spindle nose taper | BT50 | |

| Magazine capacity | pc | 24 |

| Magazine type | Round plate type | |

| Max. diameter of tools | mm | φ127 |

| Max. length of tools | mm | 350 |

| Max. weight of tools | kg | 15 |

| N.W | kg | 15000 |

| Overall dimension | mm | 3569×4100×3055 |

We are a professional vertical machiningcenter manufacturer in China.Our company is dedicated to providing our customers with high quality machinecenter, drilling milling machine, CNC lathe, CNC milling machine, verticalmilling machine, lathe and more.

Links:https://www.globefindpro.com/products/98533.html

-

Forming Machine

Forming Machine

-

XL6236 Turret Milling Machine

XL6236 Turret Milling Machine

-

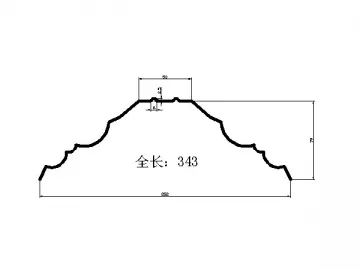

Construction Roof Panel Forming Machine

Construction Roof Panel Forming Machine

-

XL6232G Turret Milling Machine

XL6232G Turret Milling Machine

-

Steel Pipe Machine

Steel Pipe Machine

-

Sandwich Panel Machine

Sandwich Panel Machine

-

ZX6350A Drilling Milling Machine

ZX6350A Drilling Milling Machine

-

LUNAN-1660 Lathe

LUNAN-1660 Lathe

-

CLK6130E CNC Lathe

CLK6130E CNC Lathe

-

XK716 CNC Milling Machine

XK716 CNC Milling Machine

-

CK6415A CNC Lathe

CK6415A CNC Lathe

-

XHS7145 Vertical Machining Center

XHS7145 Vertical Machining Center