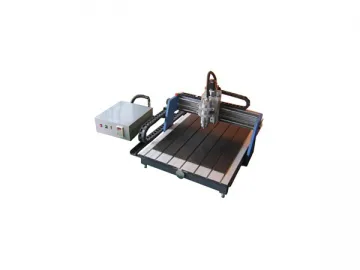

Woodworking Machining Center WMC-1

Woodworking Machining Center WMC-1

Description of Woodworking Machining Center:

1. This CNC router, a cost effective cutting machine tool for CNC machiningcenter, is controlled by a computer.

2. With features of cast steel frame construction and all-steel, moving-gantrydesign, it can machine large parts while maintaining a small, space-savingfootprint.

3. Maximum machining flexibility is available due to ATC options.

Featuresof Woodworking Machining Center:

1. Working table: 1500*3000 mm

2. Working height: 200mm (7.87") (Option 300 mm or 400mm)

3. Structure: Welded Steel (firm, whole jointing, no deformation, strongstability)

4. Pinion rack linear rail: Taiwanese Hiwin linearrail (with an extended service life)

5. Cable: Germany cable (oilproof, waterproof, anti-flex)

6. Working accuracy: < 0.01mm

7. 5.0 KW Spindle with Japanese made NSK bearing

8. Maximum spindle speed: 18000rpm/min

9. Traveling speed: 60m/min, working speed: 20m/min

10. Rack type ATC. Tool magazine capacity of 6 tools. Tool change time of only 8 seconds.

11. Bakelite vacuum table can effectively avoid distortion.

12. Panasonic servo system.

Applicationsof Woodworking Machining Center:

Our CNC Router, which is built for a wide range ofmedium-duty panel processing applications, is the perfect solution forcompanies looking for both value and high-performance in a CNC router.

SpareParts

Automatic lubrication system

Rack ATC system

High precision ball screw

Powerful vacuum pump

High-frequency and powerful spindle

LCD display

Technical Parameters of Woodworking Machining Center:

| NO. | Description | Parameter |

| 1 | X,Y,Z Working Area | 1500x3000x200mm |

| 2 | Table Size | 1575×3640mm |

| 3 | X,Y,Z Traveling Positioning Accuracy | ±0.04/300mm |

| 4 | X,Y,Z Repositioning Positioning Accuracy | ±0.05mm |

| 5 | Table Surface | Vacuum system |

| 6 | Frame | Steel Tubes |

| 7 | X, Y Structure | Rack and PInion Drive, Hiwin Rail Linear Bearings |

| 8 | Z Structure | Ball Screw, Hiwin Rail Linear Bearings |

| 9 | Max. Power Consumption(Without spindle) | 5.0Kw |

| 10 | Max. Rapid Travel Rate | 32000mm/min |

| 11 | Max.Working Speed | 20000mm/min |

| 12 | Spindle Power Motor | 8.0 KW Italian HSD Spindle |

| 13 | Spindle Speed | 6000-24000RPM |

| 14 | Drive Motors | Servo Motors and Drivers |

| 15 | Working Voltage | AC380V/50/60Hz (Option:220v,3PH) |

| 16 | Command Language | G Code |

| 17 | Operating System | SYNTEC Controller System |

| 18 | Interface | USB |

| 19 | Flash Memory | 128M (U Disk) |

| 20 | Collet | ER25 |

| 21 | X,Y Resolution | <0.01mm |

| 22 | Software Compatibility | Type3 software, Wentai Software, Artcam software |

| 23 | Running Environment | Temperature: 0℃~45℃, Relative humidity: 30%~75% |

| 24 | Packing Size | Separated: 3200X1960X1340 Integrated: 3700X1960X1870mm |

| 25 | Net Weight | 1050KG |

| 26 | Gross Weight | 1300KG |

| All parameters above subject to change without prior notice | ||

Guaranteeand Technical Support:

1.We offerone year after-sale service for our customer. Service manual and tool will begiven along with the machine.

2. All the spare parts will be maintained and changed for free except HSD Spindle( We provide half year free maintenance for HSDSpindle)

3. We provide operation training service for free in our factory

4. We can send our engineers to the customer site for the operation training ifcustomers are in charge of the training fee.

Links:https://www.globefindpro.com/products/98704.html

-

Metal Head Gasket

Metal Head Gasket

-

Small CNC Engraving Machine SE-2

Small CNC Engraving Machine SE-2

-

Heat-Resistant Bottle Crystallizer

Heat-Resistant Bottle Crystallizer

-

Mini CNC Engraver SE-1

Mini CNC Engraver SE-1

-

Full Auto Battery Charger

Full Auto Battery Charger

-

Woodworking Machining Center WMC-4

Woodworking Machining Center WMC-4

-

Manufacture Process of PET Bottle and Equipment

Manufacture Process of PET Bottle and Equipment

-

TNS Series AC Automatic Voltage Regulator 15-90KVA

TNS Series AC Automatic Voltage Regulator 15-90KVA

-

3D Laser Scanner LS-1

3D Laser Scanner LS-1

-

Advertising CNC Router RA-3

Advertising CNC Router RA-3

-

Woodworking CNC Router WR-1

Woodworking CNC Router WR-1

-

TNS Series AC Automatic Voltage Regulator 1.5-9KVA

TNS Series AC Automatic Voltage Regulator 1.5-9KVA