Automatic Push-Out Mould Press

Automatic Push-Out Mold Press

Features

1. The automatic push-out mold press is a column structure,including main machine, hydraulic station, and electric controlling cabinet.The main machine is composed of base, plunger piston, platform, beam, automaticmold pushing-out device and compulsory mold opening device.

2. Under the control of PLC, the automatic push-out moldpress achieves automatic mold closing, vulcanization timing, exhausting timeand frequency setting, mold opening, mold pushing, and so on.

3. It uses superior thermal baffle to prevent heat transfer from the hotplate to the platform.

Application

The automatic push-outmold press is used for vulcanizing all kinds of rubber and plastic model andnon-model products.

Technical Parameters ofthe Automatic Push-Out Mold Press

| Type | XLB-D600X600/1.60MN |

| Total pressure(mn ) | 1.60MN |

| Plate size(mm) | 600X600 |

| Plate daylight (mm) | 350 |

| Daylight no. | 1 |

| Piston stroke(mm) | 350 |

| Plate unit area pressure(kg/cm2) | 44.5 |

| Overall dimension(mm) | 700X1700X1800 |

| Weight(kg) | 5100 |

As an automatic push-outmold press manufacturer based in China, Judong also provides tire retread hydraulic press, BOM tire press, two roll rubbermixing mill, rubber tire shredder, conveyor belt vulcanizing machine, andrubber calender machine.

Links:https://www.globefindpro.com/products/98820.html

-

Plastic Thermoforming Machine

Plastic Thermoforming Machine

-

Rubber PVC Testing Machine

Rubber PVC Testing Machine

-

Three Roll Rubber Calender

Three Roll Rubber Calender

-

Plate Rubber Vulcanizing Press (Frame Type)

Plate Rubber Vulcanizing Press (Frame Type)

-

Conveyor Belt Vulcanizing Press

Conveyor Belt Vulcanizing Press

-

Conveyor Belt Vulcanizing Machine

Conveyor Belt Vulcanizing Machine

-

Tire Inner Tube Press

Tire Inner Tube Press

-

Hydraulic Rubber Vulcanizing Press (Duplex Full Automatic Type)

Hydraulic Rubber Vulcanizing Press (Duplex Full Automatic Type)

-

Vacuum Rubber Press Machine

Vacuum Rubber Press Machine

-

Starter Motor SM-1

Starter Motor SM-1

-

Hot Feed Rubber Extruder

Hot Feed Rubber Extruder

-

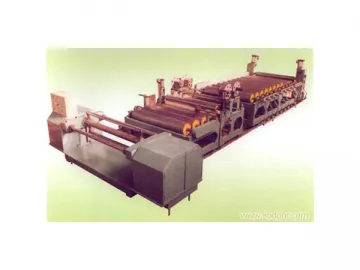

Rubber Calendar Auxiliary Machine

Rubber Calendar Auxiliary Machine