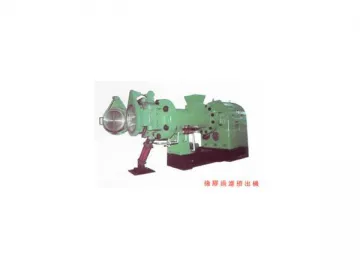

Cold Feed Rubber Extruder

Cold Feed Rubber Extruder

Features

1. Without a warm-up mill for the coldfeed rubber extruder, the investment and production cost can be reduced.

2. Rubber materials with stationarytemperature and viscidity can be fed continuously, offering high precision andhomogeneity.

3. Mounting the cold feed rubber extruderhas nothing to do with the compound-preparation workshop. It is more suitablefor a company without a mixing workshop.

4. Theextrusion head or screw of the cold feed rubber extrude can be changed toextrude different kinds of rubber products.

Application

The coldfeed rubber extruder is used for extruding half-finished rubber products suchas tire tread, rubber pipe, inner tube, cable and feeding rubber, etc.

Technical Specifications of the Cold Feed Rubber Extruder

| Type | XJW-90 | XJW-120 | XJW-150 |

| Screw dia .(mm) | 90 | 120 | 150 |

| Max. screw speed (r/min) | 45 | 40 | 35 |

| Feeding roll dia . (mm) | 72 | 120 | 120 |

| Motor model and power | Motor Z4, the power will be decided according to the extrusion head equipped. | ||

| Zone of hot water circulating | 3-4 | 3-4 | 3-4 |

| Max. total power of hot water circulation heating (KW) | 48 | 48 | 48 |

| Capacity (Kg/h) | It will be decided according to the extrusion head equipped. | ||

| Overall dimensions(mm) (Without extrusion head and hopper) | 3045x2052x1453 | 4250x2290x1490 | 4277x2211x1503 |

| Weight (Kg) | 5000 | 5500 | 8000 |

As a specialized coldfeed rubber extruder manufacturer and supplier based in China, weprovide a vast range of products that includes a conveyor belt vulcanizingmachine, plate rubber vulcanizing press, rubber tire shredder, two roll rubbermixing mill, and many others.

Links:https://www.globefindpro.com/products/98837.html

-

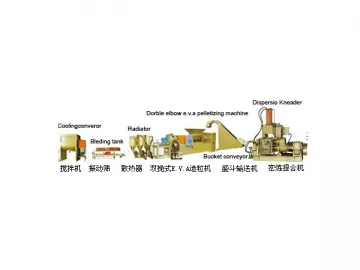

EVA Granulation Machinery

EVA Granulation Machinery

-

Rubber Batch Off Cooler

Rubber Batch Off Cooler

-

Four Roll Rubber Calender

Four Roll Rubber Calender

-

Rubber Inner Liner Extruding Calendering Line

Rubber Inner Liner Extruding Calendering Line

-

Rubber Injection Machine

Rubber Injection Machine

-

Rubber Strainer

Rubber Strainer

-

Two Roll Rubber Mixing Mill (Bearing Type)

Two Roll Rubber Mixing Mill (Bearing Type)

-

Hydraulic BOM Tire Press

Hydraulic BOM Tire Press

-

Rubber Strip Cutting Machine

Rubber Strip Cutting Machine

-

Rubber Bale Cutter

Rubber Bale Cutter

-

Rubber Pulverizer

Rubber Pulverizer

-

Two Roll Rubber Mixing Mill (H Type)

Two Roll Rubber Mixing Mill (H Type)