Rubber Batch Off Cooler

Rubber Batch Off Cooler

Features

1. Thetake-off uses steel conveying rollers equipped with a printer and slitter. Thetake-off and lifting device of the rubber batch off cooler are driven by acommon AC inverter motor. The conveying speed is adjustable.

2. Thereare two types of hanging bar driving devices. For XPG (III)-900, when thepiston bars of two side oil cylinders extend, they push the hanging bar. Theone way bearing keeps the hanging bar standing when the oil cylinder piston barretracts, therefore the hanging bar carries out intermittent movement. Otherone is driven by an AC inverter motor. The speed of the hanging bar issynchronous with the take-off and lifting device.

3. Thesheet is uniformly coated with the lubricator by dipping without polluting theenvironment. Its cooling effect is better than the spraying.

4. Thehanging up area of the rubber batch off cooler is fully closed, using theblower to blow the sheet at a slant. This improves the air flow direction andcooling effect.

5. Therobot in the take-off is advanced in China. The take-off can becontrolled automatically.

6. Theelectric control system of the rubber batch off cooler uses a reliable andautomatic PC.

Notes

1. Therubber batch off cooler can be designed as a floor-type constructionor an overhead construction. The sheet can be output on the first floor or onthe second floor or both the first and the second floor.

2. Therubber batch-off cooler is a combined construction. The customer can add orreduce the middle support as required.

3. Thecustomer can select the transverse strip cutter and the strip slitter accordingto the processing requirements.

Description

The rubber batch off cooler is coupled with an internalmixer, rubber roll-head extruder or rubber sheeting mill. The plasticizedstock, master batch and final stock from the internal mixer are calendered into a sheet via the rubber roll-head extruderor rubber sheeting mill. The sheet is dipped, cooled and dried, thencontinuously swung and piled up in the batch-off cooler.

Technical Parameters of the Rubber Batch Off Cooler

| Max. Width of the Sheet | 900mm |

| Thickness of the Rubber Sheet | 6-12mm |

| Conveying Speed | 4-40m/min |

| Distance between the Hanging Bars Effective | 152.4mm |

| Number of Functional Hanging Sheetbar | 70-90pcs |

| Max. Pendant Length of Hanging Sheet | 1400mm |

| Number of Cooling Fans | 18-26 sets |

| Temperature over Room Temperature after Rubber Sheet Cooling | 5 ℃ |

| Swing Sheet Length | 1-1.3m |

| Compressed Air Pressure | 0.5-0.7Mpa |

| Total Capacity of Power Supply | 18-34kw |

Judong is an experiencedrubber batch off cooler manufacturer based in China. We offer a wide variety ofrubber machinery that includes cold feed rubber extruder, four roll rubber calender, conveyor belt vulcanizing machine, and rubbertire shredder, among others.

Links:https://www.globefindpro.com/products/98839.html

-

Four Roll Rubber Calender

Four Roll Rubber Calender

-

Rubber Inner Liner Extruding Calendering Line

Rubber Inner Liner Extruding Calendering Line

-

Rubber Injection Machine

Rubber Injection Machine

-

Rubber Strainer

Rubber Strainer

-

Conveyor Belt Auxiliary Machine

Conveyor Belt Auxiliary Machine

-

Rubber Tire Shredder

Rubber Tire Shredder

-

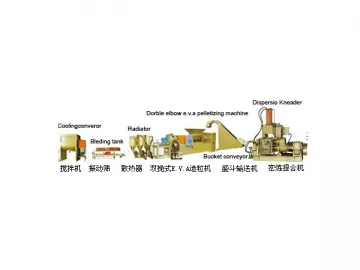

EVA Granulation Machinery

EVA Granulation Machinery

-

Cold Feed Rubber Extruder

Cold Feed Rubber Extruder

-

Two Roll Rubber Mixing Mill (Bearing Type)

Two Roll Rubber Mixing Mill (Bearing Type)

-

Hydraulic BOM Tire Press

Hydraulic BOM Tire Press

-

Rubber Strip Cutting Machine

Rubber Strip Cutting Machine

-

Rubber Bale Cutter

Rubber Bale Cutter