Internal Rubber Mixer

Internal Rubber Mixer

Features

1. Theinternal rubber mixer uses elliptical tangential rotors. The wings and working surfaces of the rotors, theinternal surfaces of the mixing chamber, and the working surfaces of the pressingram device and the discharging device are all coated with wearable hard alloyby the built-up welding method. They are durable, corrosion proof and have along service life.

2. Therotors, mixing chamber and discharging door are all structured with circulatingchannels to realize the circulation of heat transmission mediums. According todifferent processing requirements, the mixing materials may be heated by hotsteam or cooled by cold water.

3.The mixing chamber of theinternal rubber mixer is a combined configuration, which is convenient forassembling, disassembling and maintaining. The drop-door discharge device isdriven by two reciprocating oil cylinders which directly pull the locking plateto lock the discharge door. The device provides fast discharging and reliableairproof.

4.The rotors are supportedby rolling bearings, which are easy to maintain and have a long service life.

5.The transmission systemof the internal rubber mixer uses a hard facing gear reducerwhich has a compacted structure with higher transmission efficiency, lowernoise and longer service life.

6. Thepressing ram device may be driven by pneumatic cylinder or oil cylinder topress onto the mixing materials to force them equally mixed so as to increaseproductive efficiency. Matched with the electric controller, the pressing ramdevice can automatically add pressure, release pressure or just keep floating.

7. Bothmanual and automatic modes are arranged to operate PLC electric system. It iseasy to exchange the modes and reliable to operate the controller.

Application

Theinternal rubber mixer is used for plasticating andmixing rubber and plastics.

Technical Specifications of the Internal Rubber Mixer

Technical Specificationsof the Internal Rubber Mixer

| Type | X(S)M-50 | X(S)M-75/40 | X(S)M-160 | X(S)M-250/20 | X(S)M-270 | |||

| AC Drive | DC Drive | AC Drive | DC Drive | AC Drive | DC Drive | |||

| Net Chamber Volume (L) | 50 | 75 | 160 142 (2 wings) (4 wings) | 250 | 270 | |||

| Working Volume (L) | 35 | 50 | 120 105 (2 wings) (4 wings) | 140 | 188 (4 wings) | |||

| Rotating Speed of Drive Rotor (r/min) | 40 | 5-50 | 40 | 30 | 4--40 | 20 | 20/40 | 4-40 |

| Rotating Speed Ratio of Rotors | 1:1.16 | 1:1.18 | 1:1.15 | 1: : 1.16 | 1 : 1.11 | |||

| Ram Pressure on Stocks (Mpa ) | 0.25-0.32 | 0.26-0.35 | 0.36-0.48 | 0.16-0.21 | 0.35-0.47 | |||

| Compressed Air Pressure (Mpa ) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |||

| Air Consumption (m3/h) | 15 | 40 | 70 | 40 | 298 | |||

| Max. Steam Pressure (MPa ) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | |||

| Cooling Water Pressure (MPa ) | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | |||

| Water Consumption (m3/h) | 15 | 20 | 45 | 25 | 50 | |||

| Discharging Device | Hydraulic Drop Door | |||||||

| Power (KW) | 110 | 132 | 160/155 | 355 | 520 | 250 | 500/1000 | 1250 |

| Reducer | NGM Planetary Hardened-gear Speed Reducer | Dual-output Hardened-gear Speed Reducer | ||||||

| Overall Dimension (mm) | 6100x1600x3610 | 6830x1930x3800 | 8900x2800x5050 | 7600x2500x4000 | 8540x4000x5560 | |||

| Weight (Kg) | 10500 | 15000 | 31000 | 26000 | 50000 | 49000 | ||

| Note | All the models may be optionally equipped with either pneumatic or hydraulic ram. | |||||||

Judong is a specializedinternal rubber mixer manufacturer and supplier based in China. Ourcompany produces a wide variety of rubber machinery, including our two rollrubber mixing mill, BOM tire press, rubber tire shredder, tire retreading hydraulic press, and more.

Links:https://www.globefindpro.com/products/98868.html

-

Registered Embossed Laminate Flooring (Big Size)

Registered Embossed Laminate Flooring (Big Size)

-

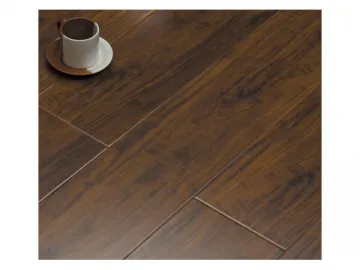

Hand Scraped Laminate Flooring

Hand Scraped Laminate Flooring

-

End-molding

End-molding

-

Wooden Finish Laminate Flooring

Wooden Finish Laminate Flooring

-

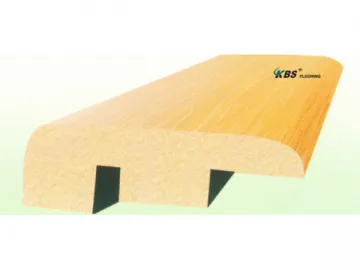

Flooring End-cap

Flooring End-cap

-

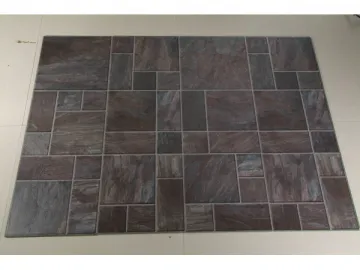

Ceramic Tile Laminate Flooring

Ceramic Tile Laminate Flooring

-

Horizontal Rubber Bias Cutter

Horizontal Rubber Bias Cutter

-

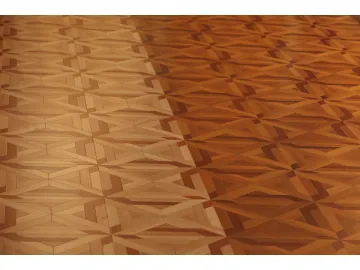

Parquet Flooring

Parquet Flooring

-

Colorful Flooring (Sunlight Colors)

Colorful Flooring (Sunlight Colors)

-

Mold-Pressed V-Bevel Flooring

Mold-Pressed V-Bevel Flooring

-

1-Strip Color Laminate Floor

1-Strip Color Laminate Floor

-

2-Strip Color Laminate Floor

2-Strip Color Laminate Floor