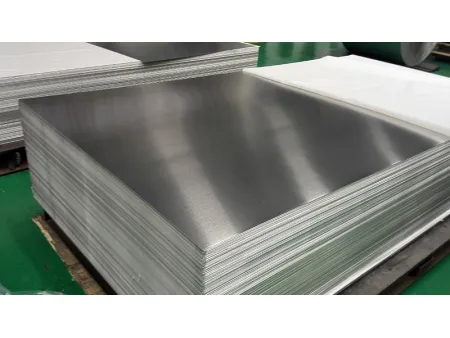

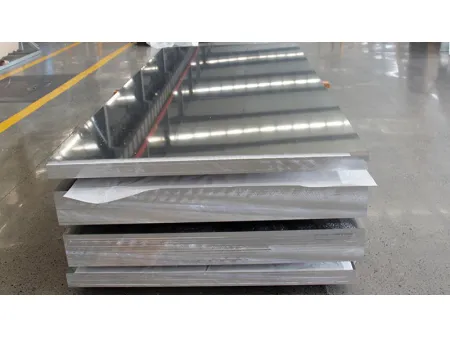

1050 Aluminum Alloy

1050 aluminum sheet/plate 1050 aluminum coil Application  Aluminum alloy state, size and mechanical properties

Aluminum alloy state, size and mechanical properties

Get in Touch

1050 aluminum alloy is used for the manufacture of heat sinks, chemical process plant equipment, food industry containers, pyrotechnic powder, lamp reflectors, cable sheathing, automotive industry, architectural and paneling, general sheet metal work, cabinets, vessels and appliances, PS CTP printing plate.

| Alloy | Temper | Thickness (mm) | Tensile strength (Mpa) | Elongation (%) | |

| Chinese standard | Value | ||||

| 1050 | O | >0.2-0.5 | 60-100 | 55-95 | ≥15 |

| >0.5-1.0 | ≥25 | ||||

| >1.0-4.5 | ≥30 | ||||

| H22 | >0.2-0.5 | 80-120 | 100-125 | ≥12 | |

| >0.5-1.0 | ≥15 | ||||

| >1.0-4.5 | ≥18 | ||||

| H24 | >0.2-0.5 | 95-130 | 120-150 | ≥6 | |

| >0.5-1.0 | ≥8 | ||||

| >1.0-4.5 | ≥10 | ||||

| H26 | >0.2-0.5 | 120-150 | 140-170 | ≥2 | |

| >0.5-1.0 | ≥4 | ||||

| >1.0-4.5 | ≥6 | ||||

| H18 | >0.2-0.5 | ≥130 | ≥170 | ≥2 | |

| >0.5-1.0 | ≥3 | ||||

| >1.0-4.5 | ≥3 | ||||

| 1050A | H18 | >0.2-0.5 | ≥140 | ≥170 | ≥1 |

| >0.5-1.5 | ≥2 | ||||

| >1.5-3.0 | ≥2 | ||||

Scan QR to Read

Links:https://globefindpro.com/products/1017.html

Links:https://globefindpro.com/products/1017.html

Recommended Products

-

3003 Aluminum Alloy

3003 Aluminum Alloy

-

MIG/TIG/MMA Welding Machine / Inverter Welder

MIG/TIG/MMA Welding Machine / Inverter Welder

-

1000 Series Aluminum Alloys

1000 Series Aluminum Alloys

-

Sealed Motorcycle Chains

Sealed Motorcycle Chains

-

1145 Aluminum Alloy

1145 Aluminum Alloy

-

Double Pitch Roller Chains

Double Pitch Roller Chains

-

Chain & Sprocket Kits for Motorcycle

Chain & Sprocket Kits for Motorcycle

-

2000 Series Aluminum Alloys

2000 Series Aluminum Alloys

-

MMA Welder / Inverter Stick Welder

MMA Welder / Inverter Stick Welder

-

3004/3104 Aluminum Alloy

3004/3104 Aluminum Alloy

-

MMA Welder / Inverter Stick Welder

MMA Welder / Inverter Stick Welder

-

MIG/TIG/MMA Welding Machine / Inverter Welder

MIG/TIG/MMA Welding Machine / Inverter Welder