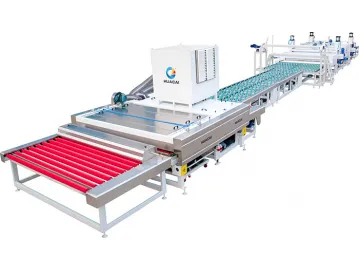

Curved and Flat Laminated Glass Line

This laminated glass line is able to produce both flat and curved laminated glasses.

Take the JC2560 curved and flat laminated glass line for example, the following show its technical parameters. General description Features The flat glass laminating line is designed with integrated PLC control, reasonable process design, high degree of automation, easy operations, good coherence among different sections, stable running, high precision and excellent synchronicity. The glass washing machine is a vital equipment influencing the cleanness and quality of laminated glass. The upper rubber rollers, brush rollers, air knives can be adjusted electrically according to the thickness of glass. The whole upper part can lift 400mm for ease of cleaning and maintenance. The upper and lower brush rollers are driven by an individual motor. The upper brush rollers consist of two hard and one soft brush roller, especially designed for washing Low-E glass and coated glass without damaging the film of the glass. Two pairs of stainless-steel air knives are adopted. The air blowers utilize soundproof foams and air inlet filter screen to deliver large air volume, low noise and good drying performance. The assembly room is comprised of assembling table, universal wheel lifting table, positioning cylinder, PVB film holder, travelling mechanism and automatic suction cup vacuum lifter to ease the assembly of multiple glasses and large glasses. After auto positioning and alignment, each piece of glasses and film will be conveyed to the glass roller press by the transition conveyer and runs at the same speed of the roller process. Thus, the assembly room is quickly vacated for the processing of next glasses. The laminated glass roller press features reasonable structure and simple operations. The main transmission Main transmission is designed with gear drive and variable frequency control for precise and easy conveying speed control. Infrared heater tube is adopted as the heating element. The distance between large press rollers is controlled by the encoder and is showed on the display for easy adjustment. CompositionThis flat glass laminating line is composed of the glass washing and drying machine, glass loading table, auto positioning device, automatic suction cup vacuum lifter, transition conveyer, PVB film laying machine (PVB film roll holder), glass heated roller press, etc.

The laminated line is mainly used for the manufacturing of laminated safety glass, bulletproof laminated glass and more. Customer needs to purchase equipment like dryer, dehumidifier and air conditioner separately.

Technical parameters| Max. glass size | 6000×2440 mm |

| Min. glass size | 400×400 mm |

| Glass thickness | 6~80 mm |

| Glass length | 26200 mm |

| Power supply | AC380V 50HZ |

| Total power | 178 KW |

The QX2500C-LOW-E glass washing machine features a horizontal structure and consists of loading, washing, drying and unloading section, air blower, electric control cabinet, etc.

FeaturesMachine construction frame is welded by high-quality profiles with a coat of supreme paint.

Transport rollers are φ85mm full-vulcanized rubber rollers with high durability.

Loading and pre-rinse section is equipped with a stainless-steel water tray and water spraying hose. All water-contact parts are made by stainless steel to prevent rust. The bottom of rubber transport rollers is dipped in water to pre rinse glass, so as to prevent contaminants entering the water tank and avoid scratching glass surface and rollers.

Washing section: Adopting a high-strength elevating screw, the upper part of the washing and drying section is motorized for up and down lifting for easy operation and maintenance. Upper brushes, rollers and air knives can lift up to 400mm according to the thickness of glass. The upper and lower brush rollers are respectively driven by two groups of motors. The upper brushes comprise two hard brushes and one soft brush to wash low-E glass and coated glass.

Drying section is designed with compact footprint, low noise and high production capacity. Fans are mounted overhead the drying section, reducing occupied floor space. Fine filter screens are adopted on the air inlets of the fan boxes which are surrounded with sound dampening materials to lower the working noise without compromising on air blast capacity. Two pairs of air knives are subjected to Italian stainless-steel processing technology. Compared to traditional drying method, air knives provide unmatched drying performance with no need of heating and the drying quality will not decline as usage years increase. The glass horizontal washer is ideal for combining with glass tempering furnace, glass screen printing line, glass laminating line, etc. which has high requirements on washing and drying effects.

Transmission mechanism is driven by bevel gear delivering high stability and durability.

Water reuse system is designed to control the water supply, save water resources and reduce production cost. Water tanks are made by superior stainless-steel panel. The joints with water pumps are equipped with "fast plugs" so that the water tanks can be easily taken out for cleaning.

Electronic control system: Motor, air blower, water pump, glass conveyor, lighting and lifting devices are all controlled by respective buttons. The horizontal glass washing machine features reasonable design, aesthetic appearance, user-friendly operations, VFD main drive and digital display of glass thickness. The lifting height is controlled by precise encoder and intelligent digital meter.

Technical parameters

| Max. glass width (mm) | 2500 |

| Min. glass size(mm) | 300×300 (diagonally placed) |

| Glass thickness(mm) | 3~25 |

| Conveying speed(m/min) | 1.0-8.0 |

| Power (KW) | 28.98 |

| Brushes (pairs) | 3 |

| Brush roller diameter(mm) | 160 |

| Transport roller diameter (mm) | 85 |

| No. of water tanks | 2 |

| Air knives (pairs) | 2 |

| Height(mm) | 860 |

| Dimension(mm) | 5800×3500×2600 |

The auto positioning device features a horizontal design, made up of machine frame, positioning mechanism, transmission system, pneumatic system, electric control system, etc.

The machine body frame is welded by standard steel materials with a paint coat.

The main drive utilizes chain conveyor, VFD and digital display.

The assembly table is equipped with a pneumatic lifting mechanism and universal wheels. The edges of the table are equipped with positioning wheels for glass positioning.

| Max. glass size(mm) | 6000×2500 |

| Min. glass size(mm) | 400×400 |

| Power (KW) | 1.5×2 |

| Conveying speed(m/min) | 0.5~8.0 |

| Height (mm) | 860 |

| Air supply pressure (MPa) | 0.6~0.8 |

| Dimension(mm) | 3600×1600×860mm |

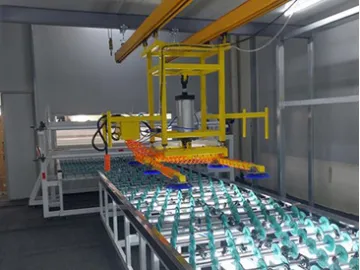

This suspended automatic suction cup vacuum lifter is used for transferring glasses, consisting of overhead crane (travelling track), pneumatic suction cups, vacuum system and electrical control system.

Vacuum pressure is controlled by the SMC high-precision vacuum generator.

The lifting of suction cups is pneumatic, reliable and safe.

The travelling of lifter is dragged by human forces.

Suction cups: 6.

Vacuum pressure: -0.05~-0.08MPa.

The travelling track of the vacuum suction cups is provided by client.

PVB roll holder

Three rolls of PVB films with different specifications can be loaded. The unwinding and rewinding of membranes are manually operated. The changeover of film roller is hoisting replacement.

GD2500 transition conveyorThe transition conveyor utilizes horizontal frame construction and consists of machine frame, transmission system and electric control system.

The machine frame is welded by steel profiles and sprayed with paint.

The transition conveyor uses chain conveyor and the conveying speed is regulated by VFD and can be digitally displayed.

| Min. glass size(mm) | 400×400 |

| Power (KW) | 1.5 |

| Conveying speed(m/min) | 0.5~8.0 |

| Height (mm) | 860 |

| Dimension(mm) | 2400×2780×860 |

The glass heated roller press is comprised of the electrical cabinet and loading, pre-heating, pre-pressing, 1st heating, 2nd heating, 3rd heating, glass curving, roll pressing and unloading section. Lifting rollers for curved glasses are equipped in the curving section and unloading section. After undergoing heating and pressing, two or more layers of glasses and a PVB/SGP interlayer are bonded together to form an initial laminated glass. Imported high-temperature-resistant rubber rollers are able to put uniform pressure on the passing through laminated glass to remove air bubbles and ensure perfect adhesion effects between the constituent elements.

The heating system features sectional control of heating temperature, precision digital temperature display and automatic constant temperature control. Stainless steel heating tubes are employed as heating elements, enhancing the heating efficiency and reducing energy consumption.

The upper and lower large press rollers are driven by individual reducers. The gap between large press rollers are controlled by PLC and displayed on the touchscreen. The diameter of the large press roller is 330mm.

The machine frame is welded by steel profiles and sprayed with paint.

Main transmission is designed with gear drive, variable frequency control and digital display of speed to achieve precise and easy conveying speed control.

Transport rollers adopt bare steel roll shafts twined around with yellow aramid cords.

Technical parameters

| Max. glass width (mm) | 2440 |

| Glass thickness(mm) | 6~80 (digital display) |

| Min. glass size(mm) | 450×450 |

| Max. glass arch length (mm) | 300 |

| Total power (KW) | 142.5 |

| Heating power (KW) | 132 |

| Conveying speed(m/min) | 0.5~2.5 |

| Air supply pressure (MPa) | 0.6~0.8 |

| Dimension(mm) | 10800×3500×2000 |

| Weight (kg) | 8600 |

Links:https://globefindpro.com/products/10178.html

-

Loading and Unloading Table

Loading and Unloading Table

-

Fire Resistant Glass Laminating Line

Fire Resistant Glass Laminating Line

-

Semi-auto Glass Vacuum Lifter

Semi-auto Glass Vacuum Lifter

-

Standard Heated Roller Press

Standard Heated Roller Press

-

Automatic Laminated Glass PVB Laying Machine

Automatic Laminated Glass PVB Laying Machine

-

MT - SUS Assembly

MT - SUS Assembly

-

Heat Soaking Oven

Heat Soaking Oven

-

Track Bolt and Nut

Track Bolt and Nut

-

Infrared Conference System Main Unit HT-8500M/HT-8510M

Infrared Conference System Main Unit HT-8500M/HT-8510M

-

Microphone LIP Battery HT-LIP1

Microphone LIP Battery HT-LIP1

-

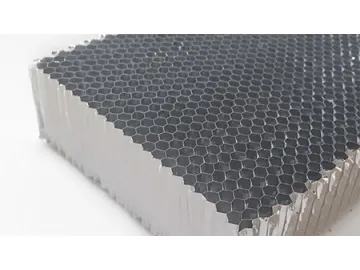

Aluminum Honeycomb Core

Aluminum Honeycomb Core

-

Infrared Conference System Main Unit HT-8700M

Infrared Conference System Main Unit HT-8700M