Automatic Paper Box Folding Gluing Machine -Ⅰ

Automatic Paper Box Folding Gluing Machine– I

Description

The paper box foldinggluing machine is used in the pasting procedure in color printing and packagingindustry. Currently, complicated and special paper boxes are glued almosttotally by hand in packaging enterprises. Pasting and gluing is one of the mostlabor intensive procedures, with one of the biggest problems of low efficiency.It is quite possibly one of the largest issues facing quality manufacturersproducing corrugated cartons and paper boxes. It brings many problems toproduction and management. To solve this problem faced by most packaging enterprisesin labor-intensive regions and countries, we produce a gluer to alleviatedependence on large numbers of practiced workers and raise efficiency and thequality of the product.

Application

This machine issuitable for pasting pharmaceutical cartons, cosmetic boxes, electriccomponents boxes, toothpaste boxes, CD boxes, etc. With features ofhigh speed, reasonable design, wide width and use of the latest technology, itis an ideal machine for the printing and packaging industries.

Technical Parameters of the Automatic Paper Box Folding Gluing Machine – I

| Model | CM-680PC | CM-780PC | CM-1050PC |

| Dimensions (L×W×H) | 12.5×1.50×1.45 m | 12.5×1.55×1.45 m | 14.5×1.85×1.55 m |

| Weight (Ton) | 5.0 | 6.5 | 9.65 |

| Total Power (Kw) | 11.5 | 11.8 | 19.5 |

| Max Speed (m/minute) | 300 | 300 | 300 |

| Board Material (gsm, Flute) | 120~700, E | 120~700, E | 200~900, E/B |

Setting Ranges

|

| CM-680 | CM-780 | CM-1050 | ||

| Straight-Line | Length max (mm) | 700 | 800 | 1000 | |

| Width (mm) | 90-680 | 100-780 | 180-1050 | ||

| Crash Lock-bottom | Length max (mm) | 600 | 700 | 1000 | |

| Width (mm) | 135-600 | 150-700 | 195-1020 | ||

| Double Wall | Length (mm) | 65-600 | 90-700 | 100-900 | |

| Width (mm) | 80-480 | 80-650 | 150-950 | ||

| 4-Corner Collapsible (optional) | Length (mm) | 160-800 | 160-900 | 150-900 | |

| Width (mm) | 150-600 | 150-700 | 260-950 | ||

| 6-Corner Collapsible (Optional) | Length (mm) | 160-800 | 160-900 | 150-900 | |

| Width (mm) | 295-600 | 295-700 | 350-950 | ||

AvailableOptions

| Automatic Set-up | Alignment system | Plasma treatment system |

| Small Box Attachment | Pocket Folder | Cold & hot gluing system |

ProductDescriptions

Enlarged Folding Section

During highspeed production, the enlarged folding section, together with the final foldingbelts, ensure a smoother and more stable operation.

Fast andversatile even for low volume work

Fast and easyset-up time means that the operator can easily change from one job to another.

Upper Glue Pots

The rationaldesign for crash lock bottom makes operation fast and simple. Glue guns can beoffered as an option.

Down GluePots

Gluingpots can be adjusted separately. They are convenient to install and remove andare easy to clean.

More StablePre-folding

The creased board is being transported forward, andlong travel distance design ensures smooth pre-folding.

ConvenientTrombone Unit

Thepressure adjustment is convenient and reliable to improve the gluing quality.It has a photoelectric counter for preset counting and automatic tickingsystem.

UniformConveying System

Itis equipped with two independent good quality imported belts that are soft andmoderate. The cylinder pressure design ensures a perfect pressing effect inthis section.

HIGHERPRODUCTIVITY, BETTER QUALITY AND LOWER COSTS

Fast andVersatile Works

Speed upto 300 meters/Min. (Max. speed)

4 & 6-Corner collapsible boxes available

Fast and Easy Set Up

1. Thru-holes on the head of every adjusting bolt enable faster set up andchangeovers.

2. The paperbox folding gluing machine is easy to set up and offers a stable glue system(Option - Hot Melt and Glue Guns)

3. Lock bottom attachments are mounted onto the upper carriers and remain onthe machine for faster set-up and changeover times.

4. It offers easy belt changing, without removal of any shafts.

Easy Operation and Maintenance

1. The machine base is made of anintegrated steel board with good rigidity and compact structure, which ensureshigh stability of the machine in operation.

2. Sophisticated & rigorous manufacturing processes and selection of goodquality standard parts and electrical components from the world’s leadingsuppliers ensure the reliability and safety in production and also keep themaintenance to the minimum.

3. The linked motor drive allows the speed of all sections of the machine to beincreased/decreased from a single control.

4. The paperbox folding gluing machine is easy to access and user friendly.

5. The wireless remote control operation and clear monitoring system make theoperator constantly master the production status, reduce the workload andgreatly shortens the set-up time, which increases efficiency.

To ensure the smooth operation of the machine, the machine must go throughregular maintenance and servicing.

1. Payattention and tighten the loose screws, bolts, nuts and other parts.

2.Adjust the tightness of the pressure belt and the position of the folding knifeaccording to different working requirements.

3. Cleanthe scraps of paper and dust in a timely manner after operation of the machine.

a.Cleaning andgrease protection of the upper and lower gluing tanks.

b. Dust removal of theelectric eye.

c. Lubrication of the copperguide film and clutch.

d. Drainage and oiling of aircompressor.

e. Lubrication maintenance ofthe nylon steel gear.

f. Grease supply maintenanceto the main shaft bearings.

4.Fill a small amount of lubricating oil on the chain, screws and nuts regularlyor clean the machine with a piece of cotton yarn dipped in oil.

5. Payattention to the running noise of the machine at all times and observe thesituation of the wear and tear parts.

6. Thepressure belts used on the folder gluer are circular belts connected by thebase unit belts. To extend the life of the belts, install the belts as shown inFigure 6-1.

a. Check the tension andtightness of the drive belt.

b. Check the abrasion of theconveyor belt.

Figure 6-1 the direction of belt interface

Chengming is a professionalautomatic paper box folding gluing machine manufacturer based in China. We providea wide variety of products, such as automatic PP plastic box folding gluingmachine, die cutting machine, laminating machine, cylindrical box curlingmachine, and more.

Links:https://globefindpro.com/products/106494.html

-

Air Entrainment Meter (Pressure Gauge Type)

Air Entrainment Meter (Pressure Gauge Type)

-

Grid Sieves

Grid Sieves

-

Digital Display Hydraulic Universal Testing Machine

Digital Display Hydraulic Universal Testing Machine

-

Cement Flexural and Compression Testing Machine (Electro-Hydraulic)

Cement Flexural and Compression Testing Machine (Electro-Hydraulic)

-

Universal Electric Hydraulic Extruder 150KN (Overload Protection)

Universal Electric Hydraulic Extruder 150KN (Overload Protection)

-

Sand Replacement Test Set (Galvanized Steel)

Sand Replacement Test Set (Galvanized Steel)

-

Portable Concrete Mixer

Portable Concrete Mixer

-

Steaming Cabinet

Steaming Cabinet

-

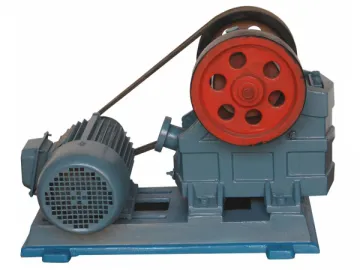

Jaw Crusher

Jaw Crusher

-

Lab Test Sieve

Lab Test Sieve

-

Automatic Asphalt Softening Point Meter (Ring and Ball Apparatus)

Automatic Asphalt Softening Point Meter (Ring and Ball Apparatus)

-

Asphalt Mixture Maximum Theory Density Meter

Asphalt Mixture Maximum Theory Density Meter