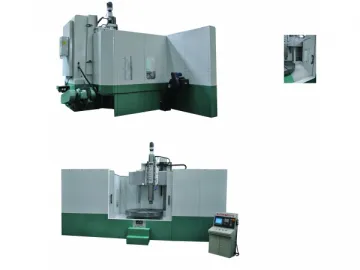

Vertical Lathe SLC200Q

Vertical Lathe SLC200Q

Features

1. This series verticallathe is suitable for finely and roughly turning cylinder and inner hole, innerand outer taper, surfacing, grooving, threading and curving of the ferrous, nonferrousmetal and some kinds of non-metal materials with carbide and porcelain tools.

2. On customers' requirement, the following can be supplied: Magazine, built-intool setting device, boring and milling, table indexing and feed, groundingcooling device, left head and whole-loop control, etc.

3. The SLC125Q feed system is driven by AC servomotor which is connected withball screw by flexible couple to implement clearance-free transmission and highprecision turning.

4. The columns, whose thermal symmetric construction is calculated by finiteelement method, stand on the table base. The effective vibration-insulatedmethod is used to ensure high rigidity and strong anti-vibration ability.

5. The table is thermal-symmetric construction. The spindle is centered by ahigh-precision double-row short cylindrical roller bearing whose radialclearance can be adjusted. With large high-precision thrust ball bearing onaxial direction as a rolling guideway, and oil temperature cooling device, thetable has high swiveling precision, larger load ability and smallerdeformation.

6. The chip conveyer and half-closed guide are equipped by customers'requirements.

7. This series vertical lathe is divided into the high-speed type and thestandard type.

8. The CNC system is SIEMENS or FANUC system, and other CNC systems can beprovided on customers' special requirements.

| Specifications | SLC125Q | SLC160Q | SLC200Q |

| Max. turning dia. | 1250mm | 1600mm | 2000mm |

| Table dia. | 1000mm | 1400mm | 1800mm |

| Max. height of work piece | 1000mm | 1000/1250mm | 1250mm |

| Max. weight of work piece | 3.2T | 5T | 8T |

| Max. turning force of vertical post | 20kn | 25kn | 25kn |

| Max. turning force of side post | 20kn | 20kn | 20kn |

| Max. table torque | 17.5kn.m | 25kn.m | 32kn.m |

| Table speeds range 2 sections/stepless | 3~120 | 2.5~100 | 2~80 |

| Table feeds range 2 sections/stepless | 0.8~86mm/min | ||

| Travel of vertical post ram | 650mm | 800mm | |

| Cross travel of arm in side post (optional) | 500mm | ||

| Vertical travel of side post (optional) | 900mm | 900mm | |

| Rapid travel speed of tool post | 1800mm/min | ||

| Arbor section size | 30 x 40mm | ||

| Main motor power | 22kw | 30kw | 37kw |

| Overall size (L x W x H) | 2360 x 2470 x 3480mm | 2660 x 2660 x 3530mm | 3150 x 3100 x 3910mm |

| Machine weight | 8.3T | 12T | 17T |

As a professional vertical lathe manufacturer and supplier based in China,J&W provides a wide range of products, including our CNC lathe, double columnmachining center, horizontal lathe, and more.

Links:https://globefindpro.com/products/106562.html

-

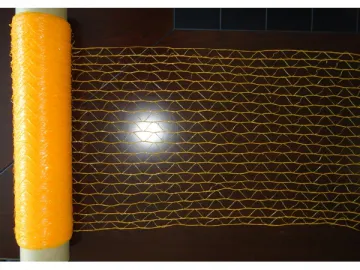

Bale Net Wrap PENW-003

Bale Net Wrap PENW-003

-

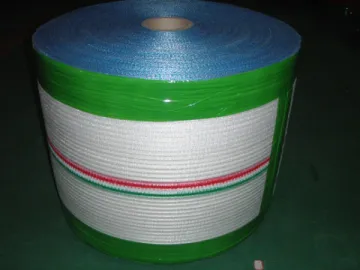

Raschel Bag on Rolls TRBR-007

Raschel Bag on Rolls TRBR-007

-

Vertical Lathe SLCM350Q

Vertical Lathe SLCM350Q

-

Pallet Netwrap PEPN-003

Pallet Netwrap PEPN-003

-

Vertical Lathe LC350Q

Vertical Lathe LC350Q

-

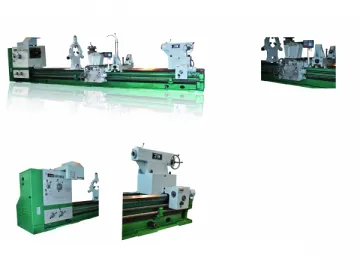

Horizontal Lathe GH61100Z

Horizontal Lathe GH61100Z

-

Raschel Bag on Rolls TRBR-004

Raschel Bag on Rolls TRBR-004

-

CNC Lathe SK61100Z

CNC Lathe SK61100Z

-

Electric Strain Direct Shear Testing Apparatus

Electric Strain Direct Shear Testing Apparatus

-

Liquid Plastic Limit United Device (Digital)

Liquid Plastic Limit United Device (Digital)

-

Standard Proctor Compactor

Standard Proctor Compactor

-

Cleveland Open Cup Flash Point Tester

Cleveland Open Cup Flash Point Tester