Air Cooling Plastic Recycling Machine

Air Cooling PlasticRecycling Machine

The air cooling plastic recycling machine uses rawmaterials like waste films of HDPE and LDPE which are extruded through theextruder before being air-cooled and hot cut into granules. The granulesfeature fine quality, and are bubble free and moisture free.

The plastic recycling machine is equipped with a forced feeder, fast meshchanger and automatic thermo controller.

Main Technical Variables

| Model | BL-90 | BL-100 | BL-110 | BL-120 |

| Diameter of Screw Stem | φ85 | φ95 | φ105 | φ115 |

| Screw ratio (L/D) | L/D 20:1 -22:1 | L/D 20:1 -22:1 | L/D 20:1 -22:1 | L/D 20:1 -22:1 |

| Rotational Speed of Screw Stem | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min |

| Main motor power | 18.5kw | 22kw | 30kw | 37kw |

| Output | 68kg/h | 95kg/h | 120kg/h | 135kg/h |

| Machine weight (kg) | 2600kg | 2800kg | 3000kg | 3200kg |

| Dimensions (L×W×H) (mm) | 4000*1500*1800 | 4200*1500*1800 | 4400*1500*1800 | 4600*1500*1800 |

As a professional air cooling plastic recycling machinemanufacturer in China, we also offer stretch film rewinding slitter, labelslitting rewinding machine, color mixer, etc.

Links:https://globefindpro.com/products/106630.html

-

Single-Layer Stretch Film Making Machine

Single-Layer Stretch Film Making Machine

-

Cling Wrap Film Making Machine

Cling Wrap Film Making Machine

-

Double-Color Flexographic Printing Machine / Non-Woven Fabric Printing Machine

Double-Color Flexographic Printing Machine / Non-Woven Fabric Printing Machine

-

Three Layer Film Blowing Machine

Three Layer Film Blowing Machine

-

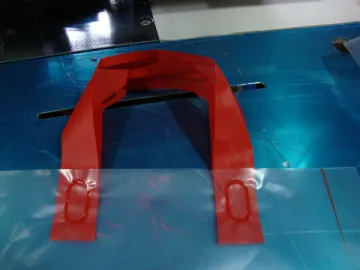

Soft Handle Sealing Machine

Soft Handle Sealing Machine

-

Hand Feeding Preform Automatic Blow Molding Machine

Hand Feeding Preform Automatic Blow Molding Machine

-

Plastic Recycling Granulator

Plastic Recycling Granulator

-

Six-Color Flexo Printing Machine / Non-Woven Fabric Printing Machine

Six-Color Flexo Printing Machine / Non-Woven Fabric Printing Machine

-

Rotogravure Printing Machine

Rotogravure Printing Machine

-

T-Shirt Bag Making Machine With Puncher

T-Shirt Bag Making Machine With Puncher

-

Horizontal Slitting Rewinding Machine

Horizontal Slitting Rewinding Machine

-

Laminate Sealing Film

Laminate Sealing Film