2-Ply Corrugated Board Production Line

2-Ply Corrugated Board Production Line

Part One: RS-1500MA Electric Type Mill Roll Stand

Listed below are the features of the mill roll stand, part of a 2-ply corrugated board production line.

1. The lifting and lowering, open-close and right-left adjustment of arms are operated by an electric motor which was made in China by a famous brand.

2. The pick-up cylinder used with cast iron curve structure, slinky, firm and stable.

3. Two work positions of the electric type mill roll stand can clamp two scrolls at the same time and load or unload scrolls without stopping production. This improves the production efficiency of our corrugated board production line.

4. Moving type is electric swing type.

Technical Specifications

1. Max. paper diameter | 1500mm |

2. Min paper diameter | 400mm |

3. Max. loading weight of each side | 2500kg |

4. Working area | Max1600mm Min: 800mm |

5. Diameter of jumbo roll | ¢400mm - ¢1500mm |

6. Max. loading on one side | 2500kg |

7. Total power | 5.2kw |

8. Working power | 380V, 50Hz |

9. Dimension (L×W×H) | 3350×2800×1400mm |

Part Two: SF-280S Single Facer (Electric heating: 50m/min)

Below are the features of the single facer, a second part of 2-ply corrugated board production line.

1. Fingerless type single facer ensures high quality flute.

2. Air-draft gauge of lower corrugating roller is within 2mm, it could reduce pressing stripe to form high quality flute.

3. Driving part uses gimbal type to make the single facer far away from vibration source.

4. Using reduce box, which uses submerged lubrication, with seal type gear driving, reduces shock of single facer.

5. Using pneumatic control gluing roller to finish automatic circle supply glue with buffing function.

6. Gluing width can be adjusted by fasten. This improves the flexibility of the corrugated board production line.

7. SF-280S single facer uses anilox type and chromed pasting roller.

8. Upper-lower corrugating roller is made of 48CrMo high quality alloy steel, which is heat treated with hardness HRC55-60. Surface with grinding and chromed.

9. Flute: A flute: 4.7mm, C flute: 3.75mm, B flute: 2.75mm, E flute: 1.8mm

Main Part Specifications

Upper corrugating roller diameter: ¢278mm, made in Beijing

Lower corrugating roller diameter: ¢280mm, made in Beijing

Pressure roller diameter: ¢292mm, 45# high quality steel with quenching

Pasting roller diameter: ¢230mm, 45# high quality steel, surface with special chromed anilox

Doctor roller diameter: ¢120mm, 20# seamless pipeline, made in Chengdu steel group

Pre-heater roller diameter: ¢265mm, Jinna steel group, 20G steel, thickness: 20mm

Raw Materials and Bought-In Components

1. Wallboard and seat of the machine: HT200

2. Rotary joint and metal hose: made in Wanxiang group (largest manufacturer in China)

3. Common bearing and bearing seat: made in China by famous brand.

4. Motor: main motor: 15kw, 1set

5. Vacuum motor: 7.5kw, 1set

7. Electrical appliance: Chint, China

8. Pneumatic parts: Airtac, made in Taiwan

Technical Specifications

1. Manufacture width | Max 1600mm |

2. Max manufacture speed | 100mm/min Normal work speed: 80mm/min |

3. Work pressure | 0.6~0.9MPa Steam pressure: 0.9~1.3MPa |

4. Steam consumption | 0.5~0.8t/h Temperature requirement: 160~200℃ |

5. Whole machine power | 33.7kw Work power: 380V, 50Hz |

6. Dimension (L×W×H) | 3400mm×1900mm×1800mm |

Part Three: MC-10 Rotary Cutting Machine

:MC-10 Rotary Cutting machine

The rotary cutting machine is also a component of our 2-ply corrugated board production line.

Features

1. With slitting function, this rotary cutting machine functions to cut 2-layer carton sheet.

2. Using speed motor and speed changer to control cutting length, the rotary cutting machine features big strength for cutting and low noise. The corrugated board production line inherits the above advantages.

Technical Specifications

1. Maximum production speed | 70m/min |

2. Maximum width | 1700mm |

3. Power consumption | 3kw |

4. Cut length accuracy | ±2.5mm |

5. Whole machine power | 33.7kw Work power: 380V, 50Hz |

6. Dimension (L×W×H) | 3400mm×1900mm×1800mm |

As a professional corrugated board production machine manufacturer and supplier, based in China, we at AMC also provide flexo printer slotter, die cut machine, carton slotter, carton gluer and stitching machine, etc. In order to satisfy customer demands, we also manufacture carton machinery, paper edge protector machinery and paper cup machinery and more. If you have any questions about any of our products, please feel free to contact us.

Links:https://globefindpro.com/products/107011.html

-

Die Cutting Creasing Machine

Die Cutting Creasing Machine

-

Automatic Rotary Die Cutter

Automatic Rotary Die Cutter

-

Slitter Scorer

Slitter Scorer

-

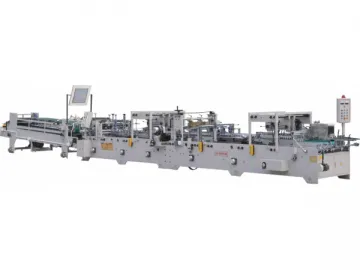

FH800PSW High Speed Automatic Folder Gluer

FH800PSW High Speed Automatic Folder Gluer

-

Stitching Machine Heavy Type

Stitching Machine Heavy Type

-

Semi Automatic Rotary Die Cutter

Semi Automatic Rotary Die Cutter

-

FH1450PSW High Speed Automatic Folder Gluer

FH1450PSW High Speed Automatic Folder Gluer

-

Stainless Steel Wire Mesh

Stainless Steel Wire Mesh

-

Hamburger Gluer Machine L800

Hamburger Gluer Machine L800

-

Paper Bowl Forming Machine DB-B

Paper Bowl Forming Machine DB-B

-

Paper Edge Protector Line ZJK120C

Paper Edge Protector Line ZJK120C

-

Roll Cutting Machine

Roll Cutting Machine