BFRP Rebar

BFRP Rebar

Made of highstrength basalt fiber and vinyl epoxy resin which have been pultrued, winded,surface painted, BFRP rebar is a construction material that features high strength and excellentcorrosion resistance. It can also be composite molded and manufacturedcontinuously. Compared with traditionalreinforced concrete structure, BFRP rebar has superior mechanical properties, physical properties, chemical properties and it will extend the life ofthe reinforced concrete structure in obviously corrosive conditions.

Features

1. The tensile strength of BFRP rebar is two times more than ordinary steel ofthe same size.

2. It has excellent corrosion resistance which can’t be realized by any otherfiber fabric.

3. The density of BFRP rebar is just about 1/4 of ordinary steel.

4. It has excellent wave transparence and no shielding.

5. With its similar thermal expansion coefficient, the BFRP rebar won’t producehigh temperature stress.

6. No electric conductivity nor thermal conductivity.

7. BFRP rebar can be prefabricated to standard curve and other shapes.

Application

1. BFRP rebar can be used tosolve the problem of corrosion resistance and lifetime of bridges as well asreinforced concrete structures in acidic and alkaline areas such as north areaand wet south area.

2. It can be used to solve the difficult technical problem of the continuousreinforced concrete roads in highways and the welding of the reinforcedconcrete.

3. By mitigating the weight of the bridge, it can enhance the bearing capacityas well as the life span.

4. BFRP rebar can be used to permanently anchor the mine, tunnel and roadslope.

5. Simplified construction difficulty results in the improving of efficiency,reducing the construction period and saving the cost of the production.

6. BFRP rebar can reduce construction cost and the total project expenseas well as maintenance costs.

Technical Specifications

| Name | BFRP | |

| Density(g/㎝³ ) | 1.9-2.1 | |

| Tensile strength (MPa) | ≥1000 | |

| Tensile elastic modulus (GPa) | ≥50 | |

| Yield strength (MPa) | ≥600 | |

| Bending strength (MPa) | ≥900 | |

| Bending elastic modulus (GPa) | ≥45 | |

| Compressive strength (Mpa) | ≧500 | |

| Elongation (%) | ≥1.8 | |

| Bond strength with concrete (Mpa) | ≥35 | |

| Coefficient of thermal expansion×10-6/℃ | Vertical | 9-12 |

| Horizontal | 21-22 | |

| Alkaline resistance (%) | ≥85 | |

| Magnetic susceptibility (1×10-5CGSM) | ≤5×10-7 | |

Notes

1. Alkaline resistance refers to thestrength retention of the filament at break after soaking in the saturatedsolution of 100℃ Ca(OH)2.

2. Magnetic susceptibility standard: 4π×10-3SI(1×10-5CGSM)

3. Barcol hardness: ≥65

4. Life: ≥60 years (the minimum value tested under 13PH alkalinecondition)

5. Creep: BFRP won’t creep and breakunless sustained load surpass 60% over short-term load

6. Shaping and bending: BFRP can still reach 40% of ultimate strength afterbending

SHUANGYI is a China-based BFRP rebar manufacturer and supplier. We offer BFRP rebars, paddles, aramidunidirectional fabrics, etc. Our highquality products are offered at competitive prices. We can supply the full chain of manufacturingcar large surrounded parts, modified car accessories, etc. right here in China. Our lower manufacturing cost saves yourpurchasing cost. More details of each of our products are shown on thedescription page.

Links:https://globefindpro.com/products/107229.html

-

SMD Indoor LED Display

SMD Indoor LED Display

-

Caps, Rotors, Points and Condensers for Racing Distributors

Caps, Rotors, Points and Condensers for Racing Distributors

-

Wing Body Fairing

Wing Body Fairing

-

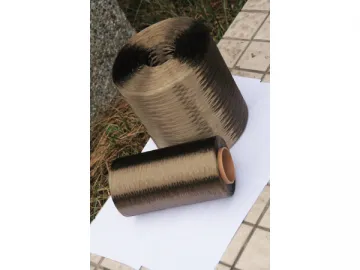

Continuous Basalt Fiber Roving

Continuous Basalt Fiber Roving

-

Marine Fuel Pumps

Marine Fuel Pumps

-

Chrome Plated Street Fuel Pumps

Chrome Plated Street Fuel Pumps

-

BFRP Laminate

BFRP Laminate

-

T5 10w 1.5m LED Tube Light

T5 10w 1.5m LED Tube Light

-

T5 12w 1.5m LED Tube Light

T5 12w 1.5m LED Tube Light

-

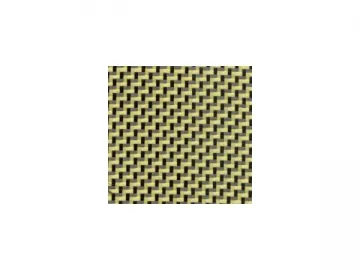

Carbon Fiber and Aramid Fiber Fabric

Carbon Fiber and Aramid Fiber Fabric

-

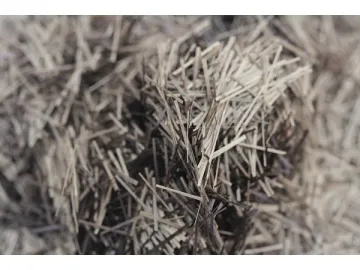

Mortar and Concrete Use Basalt Chopped Strand Fiber

Mortar and Concrete Use Basalt Chopped Strand Fiber

-

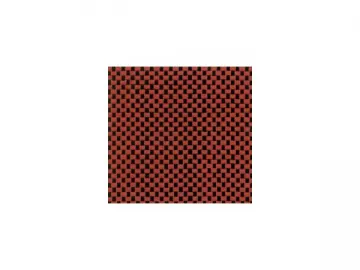

Carbon Fiber and Colorized Aramid Fiber Fabric

Carbon Fiber and Colorized Aramid Fiber Fabric