Plastic Blow Molding Machine 1.8L (Flat Movement, Double Station )

Plastic Blow Molding Machine 1.8L (Flat Movement, Double Station)

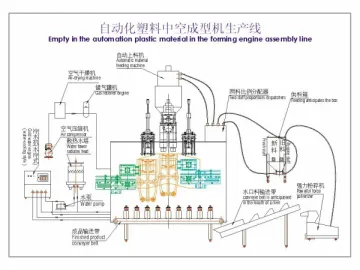

Technical Specifications of SPB(A)-1.8L Precise Plastic Blow Molding Machine (Single/Double Layer, Flat Movement, Double Station, Rectangle Formwork)

| Model | SPB-1.8L1JD (one head) | SPB-1.8L2JD (Two head) | SPB-1.8L3JD (Three head) | SPB-1.8L4JD (Four head) | SPB-1.8L1JUD Double layer/One head | SPB-1.8L2JUD Double layer/One head | |

| Screw diameter | mm | 45/50 | 45/50 | 45/50 | 45/50 | 50/35 | 50/35 |

| Screw L/D ratio | L/D | 22:1/24:1 | 22:1/24:1 | 22:1/24:1 | 22:1/24:1 | 24:1/24:1 | 24:1/24:1 |

| Drive motor | KW | 7.5/11 | 7.5/11 | 7.5/11 | 7.5/11 | 11/5.5 | 11/5.5 |

| Inverter | KW | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Screw rotating speed | r.p.m | 10-75 | 10-75 | 10-75 | 10-75 | 10-75 | 10-75 |

| Number of heaters | ZONE | 5 | 6 | 8 | 9 | 11 | 13 |

| Heating capacity | KW | 6 | 7.2 | 9.6 | 12.6 | 13.2 | 15.6 |

| Extruding capacity per hour HDPE/PP | Kg/h | 35-50 | 35-50 | 35-50 | 35-50 | 50/25 | 50-25 |

| PETG/PVC/PC | Kg/h | 25-35 | 25-35 | - | - | - | - |

| Extruding mouth outer die | mm | 90 | 55 | 45 | 35 | 90 | 55 |

| Mold center distance | mm | - | 100 | 70 | 50 | - | 100 |

| Mold stroke | mm | 110-330 | 110-330 | 110-330 | 110-330 | 110-330 | 110-330 |

| Length of mold capacity | mm | 50-250 | 50-250 | 50-250 | 50-250 | 50-250 | 50-250 |

| Die width | mm | 60-260 | 60-260 | 60-260 | 60-260 | 60-260 | 60-260 |

| Vice-thickness | mm | 110-150 | 110-150 | 110-150 | 110-150 | 110-150 | 110-150 |

| Dry cycle per hour | Time/h | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Clamping force | Ton | 3 | 3 | 3 | 3 | 3 | 3 |

| Oil tank capacity | L | 150 | 150 | 150 | 150 | 150 | 150 |

| Pressure of air | Kg/cm² | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Air Volume | m³/min | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Cooling Water pressure | Mpa | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 |

| Cooling Water Consumption | L/min | 30 | 30 | 30 | 30 | 30 | 30 |

| Min./Max. diameter of product | mm | 15-120 | 10-90 | 5-50 | 5-40 | 15-120 | 10-90 |

| Weight of product | G | 10-90 | 10-60 | 5-40 | 5-25 | 10-90 | 10-60 |

| Product capacity | L | 1.8 | 0.75 | 0.3 | 0.12 | 1.8 | 0.75 |

| Total Electrical Power Rating | Kw | 16/22.5 | 22.2/23.7 | 226-26.1 | 25.6/29.1 | 35.2 | 37.6 |

| Average Electrical Power Rating | Kw | 9.9/11.8 | 10.65/13 | 11.45/14.3 | 12.3/16 | 19 | 20.6 |

| Machine net weight | Ton | 1.5/2.3 | 1.5/2.3 | 1.5/2.3 | 1.5/2.3 | 2.6 | 2.6 |

| Gross weight | Ton | 1.8/2.6 | 1.8/2.6 | 1.8/2.6 | 1.8/2.6 | 2.9 | 2.9 |

| Machine dimension(L×W×H) | m | 2.46×1.66 ×2.24 | 2.46×1.66 ×2.24 | 2.46×1.66 ×2.24 | 2.46×1.66 ×2.24 | 2.46×1.66 ×2.24 | 2.46×1.66 ×2.24 |

| Box dimension | m³ | 9.2 | 9.2 | 9.2 | 9.2 | 9.2 | 9.2 |

Besides the types in the form above, our company welcomes consumers to have various needs and we will produce and offer new types according to your needs. Our company reserves the right to adjust the product design and norm without notification.

Scan QR to Read

Links:https://globefindpro.com/products/107503.html

Links:https://globefindpro.com/products/107503.html

Recommended Products

-

Rotary Die Board Laser Cutting Machine

Rotary Die Board Laser Cutting Machine

-

Plastic Blow Molding Machine 2.5L

Plastic Blow Molding Machine 2.5L

-

AI10 P10mm

AI10 P10mm

-

E1688 P16mm

E1688 P16mm

-

Die Board Laser Cutting Machine 200B

Die Board Laser Cutting Machine 200B

-

A2588 P25mm

A2588 P25mm

-

Sheet Metal Laser Cutting Machine 200A1225, 350A1225, 600A1225

Sheet Metal Laser Cutting Machine 200A1225, 350A1225, 600A1225

-

A1688 P16mm

A1688 P16mm

-

Die Board Laser Cutting Machine 200 AII, 350AII

Die Board Laser Cutting Machine 200 AII, 350AII

-

AI06 P6mm

AI06 P6mm

-

Plastic Blow Molding Machine 1L (Flat Movement, Double Station )

Plastic Blow Molding Machine 1L (Flat Movement, Double Station )

-

Golf Fairway Wood

Golf Fairway Wood