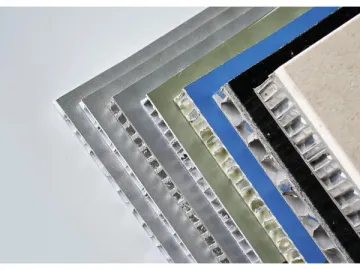

Aluminum Honeycomb Panel

Aluminum Honeycomb Panel

Description

The aluminum honeycomb panel uses high quality 3003H24 aluminum sheet and5052AH14 Al-Mn sheet. For 0.8-1.5mm thick aluminum sheetroller coated with PVDF, it is suggested to have 0.6-1.0mm thick bottom plateand 10mm-25mm total thickness. The 3003 aluminum honeycomb core is a hexagonwith side length of 5-6mm, and aluminum foil thickness of 0.04-.06mm. Through the use of high polymer adhesive film,modified epoxy and fully automatic equipment, the aluminum honeycomb panel ismade by pressurizing and high temperature laminating in a totally enclosedenvironment. This avoids the problem of brittle adhesive layer existing inother honeycomb panels. The honeycomb panel offers high quality, light weight,high strength, luxurious design, and high stability even in very humid or hotenvironment.

We at SEVEN Panel use advanced, fully automatic honeycomb panel laminatingequipment, which provides high efficiency and stable performance. The honeycombpanel is made through the process of low temperature laminating--mediumtemperature laminating--high temperature laminating-- medium temperaturelaminating--low temperature laminating--shaping and cooling--finished productoutput. With continuous working, the production line makes sure the aluminumhoneycomb panel is straight, flat, and firmly bonded, and has high strength andreliable quality.

Features

1. The aluminum honeycombpanel provides light weight, high rigidity, high structural stability, andstrong resistance to wind load.

2. It offers sound and heat insulation, and excellent fire and shock proofingproperties.

3. The honeycomb panel looks neat and elegant, is durable, and comes in a widerange of colors.

4. The panel is easy and fast to install and creates good decorative effects.

Specifications of PVDF Coated AluminumHoneycomb Panel

1. Thickness: 10mm-200mm

2. Size: 1,200×2,500mm (regular size); Customizable

3. Panel: The SEVEN Color brand aluminum honeycomb panel uses 0.5-1.5mm thicksheet alloy; KYNAR500 fluorocarbon resin paint or polyester resin coating canbe used; the panel size and materials (such as stainless steel panel, fireproofpanel, color plate, natural stone, etc.) can be customized to meet variousneeds.

4. The glue used is thermosetting epoxy adhesive film, gel-glue, etc.

5. The pain color is gloss silver, black, white, or customized.

Application

The aluminum honeycomb panel is used for curtain wall and exterior wallcladding, interior decoration, advertising boards, aviation, indoor partitions,display stands, body of commercial transport vehicles and container cars,eco-friendly furniture, buses, trains, and more.

Related Products

In addition to the aluminum honeycombpanel, we at SEVEN Panel provide stainless steel honeycomb panel, marblehoneycomb panel, anodized aluminum honeycomb panel, titanium honeycombpanel and copper honeycomb panel.

Founded in1996, SEVEN Panel is a China-based aluminum honeycomb panelmanufacturer which has been ISO9001:2008 and ISO14001:2004 certified. Weprovide PVDF aluminum composite panel, composite metal roof system, polyesteraluminum composite panel, fireproof aluminum composite panel, aluminum sheet,etc. Our products are reliable in quality and reasonable in price. Our aluminumbuilding materials have been exported to Australia,India, Indonesia, Turkey,Thailand, Singapore, Malaysia,Burma, Iran, Saudi Arabia and other countries. Weare located in Liaocheng City, which is near to Qingdao Port.This location helps us and our customers to reduce transportation fees andprovides us with easy access to abundant labors and land, enabling us to cut productioncost effectively. For more information about any of our products, please feelfree to contact us at SEVEN Panel.

Links:https://globefindpro.com/products/107762.html

-

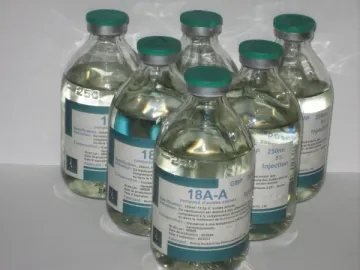

Amino Acid Injection (18AA)

Amino Acid Injection (18AA)

-

Fructose Injection

Fructose Injection

-

SEVEN-ZIP Metal Roofing System

SEVEN-ZIP Metal Roofing System

-

SEVEN-SEAM Metal Roof System

SEVEN-SEAM Metal Roof System

-

Warehousing Solution

Warehousing Solution

-

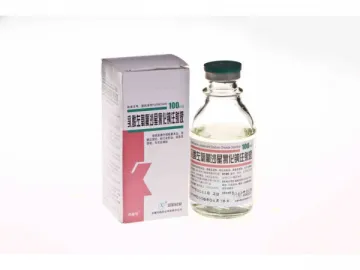

Levofloxacin Lactate Injection

Levofloxacin Lactate Injection

-

Metformin Hydrochloride Extended-release Tables

Metformin Hydrochloride Extended-release Tables

-

Wood Aluminum Composite Panel

Wood Aluminum Composite Panel

-

ZS1-12kV AC Metal-Clad Withdrawable Enclosed Switchgear Cabinet

ZS1-12kV AC Metal-Clad Withdrawable Enclosed Switchgear Cabinet

-

Fuse Holder

Fuse Holder

-

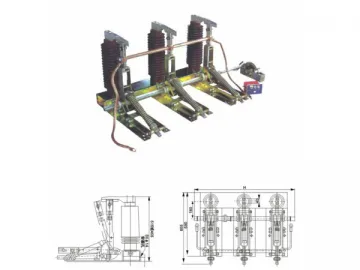

Earth Switch

Earth Switch

-

VD4 Vacuum Circuit Breaker

VD4 Vacuum Circuit Breaker