Wind Turbine Hubcap

Wind Turbine Hubcap

Advanced Technology

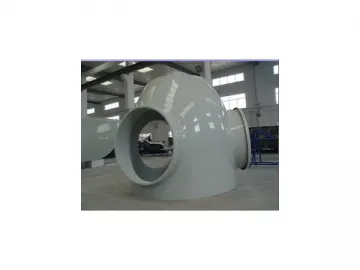

Our company is equipped with professional research and technical personnel forthe primary design and optimization of the wind turbine hubcap and for thedesign and manufacture of large scale mirror mold. Our wind turbine hubcap is manufactured withimported products as raw materials and has a service life of at least 20years. The mold surface is up to A-levelstandard and has a design life of 600 sets.

Features

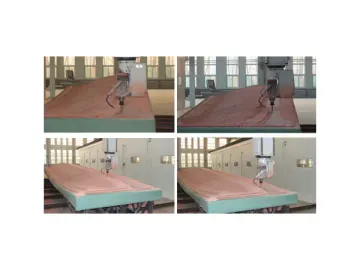

1. The wind turbine hubcapis manufactured with various processes, including roll coating, LRTM, vacuum assisted perfusion, etc.

2. An imported gel spraying machine and resin roll coater ensure accuratematching of raw materials and even coating of the wind turbine hubcap.

Detecting Capacity

Our company is well equipped with detection and testing facilities, including auniversal material testing machine, impact testing machine, thickness tester,articulated arm coordinate measuring machine, chemical lab, etc. All thesefacilities can be used for the detection and testing of raw materials andproducts in terms of various typical properties.

Application

Manufactured with GFRP as raw materials, our wind turbine hubcap is used as thebody shell for wind power generators. Ourwind turbine hubcap can be used for wind power generators of 850KW, 1MW, 1.5MW,2MW, 3MW, etc.

Service

Our company an excellent post-sales service system and is equipped withprofessional technicians to help clients solve any problems related to our products.

SHUANGYI is a major manufacturer and supplier of wind turbine hubcaps, based in China. Our company offers a wide range of products,including wind turbine hubcaps, wing bodyfairings, truck engine covers, etc. Our high quality productsare competitively priced. We can supplythe full manufacturing chain of carbumpers, wind turbine nacelle cover molds, etc. right here in China. Our low manufacturing cost can help you savepurchasing cost. If you would like moreinformation about any of our products, please turn to the corresponding pagesfor a detailed description.

Links:https://globefindpro.com/products/108874.html