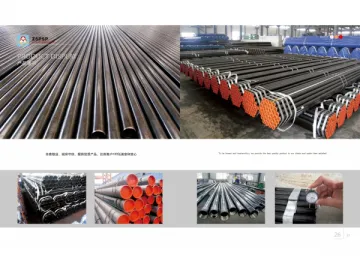

Coating Steel Pipes

Coating Steel Pipes

Technical specifications

Anticorrosive Coating Material Parameter | Three LayerPECoating | Two Layer PECoating | Three Layer PPCoating | Single Layer FBECoating |

Electric Strength | Excellent | Excellent | Excellent | Excellent |

Water Absorption Rate | Excellent | Excellent | Excellent | Fair |

Cathode StrippingResistance | Excellent | Good | Excellent | Excellent |

Adhesive Power | Excellent | Good | Excellent | Excellent |

Impact Resistance | Excellent | Good | Excellent | Poor |

Microbiological Resistance | Excellent | Good | Excellent | Fair |

Chemical Resistance | Excellent | Excellent | Excellent | Excellent |

Soil Stress Resistance | Excellent | Fair | Excellent | Fair |

Bend Ability | Excellent | Fair | excellent | Fair |

Maximum Operating Temperature | 85°C | 75°C | 105°C | 85°C |

Abrasive Resistance | Excellent | Excellent | Excellent | Fair |

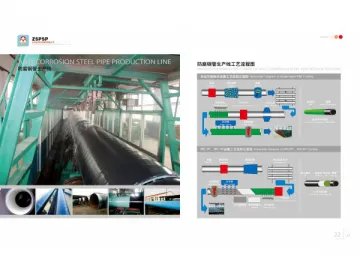

Coating steel pipe process flow

The process steps are as follow: Feeding raw materials - feeding the bare pipe - preheating the pipe - shot blast cleaning the pipe surface - dust treatment - epoxy power coating - adhesive coating - PE coating - water cooling - jet-painting marks - anticorrosive coating thickness detection - peel the pipe end - appearance check - binding power test - packing the pipe end - final product.

ZHONGSHUN is a coating steel pipes manufacturer and supplier. We also offer line pipesand pilings. Our high quality products are offered at competitive prices. ZHONGSHUN is located in China, where the full chain of manufacturing API 5CT casings and galvanized steel pipes can be completed, even in one city, which helps save our production cost. Our lower manufacturing cost saves your purchasing costas well. More details of each product are shown on the page with description.

Links:https://globefindpro.com/products/109492.html

-

EN10219-2 ERW Steel Pipe

EN10219-2 ERW Steel Pipe

-

ASTM A252 Spiral Steel Pipe

ASTM A252 Spiral Steel Pipe

-

ERW Steel Pipes

ERW Steel Pipes

-

EN 10219-2 Welded Steel Pipe

EN 10219-2 Welded Steel Pipe

-

GB/T9711.1 ERW Steel Pipe

GB/T9711.1 ERW Steel Pipe

-

GB/T 9711.1 HSAW Steel Pipe

GB/T 9711.1 HSAW Steel Pipe

-

Delustrant (Matting Agent)

Delustrant (Matting Agent)

-

API 5CT ERW Steel Pipe

API 5CT ERW Steel Pipe

-

Galvanized Steel Pipes

Galvanized Steel Pipes

-

3PP Coating Steel Pipe

3PP Coating Steel Pipe

-

GB/T 9711.2 Spiral Welded Steel Pipe

GB/T 9711.2 Spiral Welded Steel Pipe

-

Humidity Control Silica Gel

Humidity Control Silica Gel