Medical Devices Rapid Prototyping

Medical Devices Rapid Prototyping

Some of prototypes for pharmaceutical equipment GL made are as follows

Detectors Special Trolley Model Rapid Prototype Size: 500*480*1250 mm

Material: PVC, etc.

Weight: 5350g

Process: Machining/Vacuum casting/3D printing

Finish: Deburring

Lead time: 15 Days

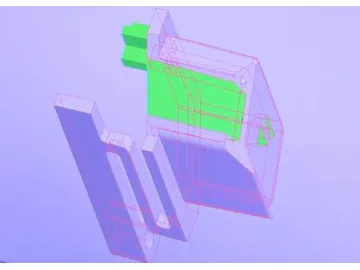

Small Transparent PC Case Vacuum Casting Size: 52*25*14 mm Material: PC Weight: 4g Process: Vacuum casting Finish: Deburring, Polish Lead time: 5 Days

Nylon Case Prototype For Thermometer Size: 122*21*16mm

Material: Nylon

Weight: 23g

Process: 3D printing

Finish: Deburr, Polish

Lead time: 5 Days

ABS Polished Front Panel Case Prototype Size: 545*365*68 mm Material: ABS Weight: 1325g Process: Machining Finish: Deburring, Polish, silkscreen, Painting Lead time: 5 Days

Detection Devices Body Shells Prototyping Size: 245*188*34 mm

Material: abs

Weight: 353g

Process: Machining

Finish: Deburring, Painting

Lead time: 7 Days

Office Seats Handle Spare Parts Prototype Size: 320*68*14 mm Material: ABS Weight: 88g Process: Machining Finish: Deburring, Painting Lead time: 7 Days

Medical Devices Beds Parts Prototype Service Size: 540*320*43 mm

Material: Nylon

Weight: 1130g

Process: Machining

Finish: Deburring, Polish

Lead time: 10 Days

Body Case Rapid Prototype Service Size: 446*160*455 mm

Material: ABS

Weight: 2246g

Process: Machining, Vacuum

Finish: Power coating

Lead time: 10 Days

Prototypes of The Thermometer ABS Case Size: 164*20*14 mm Material: ABS, rubber Weight: 25g

Process: Machining, vacuum casting

Finish: Painting

Lead time: 7 Days

With the improvement of medical devices and technology, pharmaceutical equipment updates and upgrades as well. Once the appearance and model designed, you have to make rapid prototypings to verify the feasibility of your idea. The main difficulty in medical industry is the materials hard to machine, complex shapes and the extremely high demand for precision. GL is equipped with 5-axis, 4-axis and 3-axis CNC machining centers which can meet your demand perfectly.

Some of prototypes for pharmaceutical equipment GL made are as follows

Detectors Special Trolley Model Rapid Prototype Size: 500*480*1250 mm

Material: PVC, etc.

Weight: 5350g

Process: Machining/Vacuum casting/3D printing

Finish: Deburring

Lead time: 15 Days

Small Transparent PC Case Vacuum Casting Size: 52*25*14 mm Material: PC Weight: 4g Process: Vacuum casting Finish: Deburring, Polish Lead time: 5 Days

Nylon Case Prototype For Thermometer Size: 122*21*16mm

Material: Nylon

Weight: 23g

Process: 3D printing

Finish: Deburr, Polish

Lead time: 5 Days

ABS Polished Front Panel Case Prototype Size: 545*365*68 mm Material: ABS Weight: 1325g Process: Machining Finish: Deburring, Polish, silkscreen, Painting Lead time: 5 Days

Detection Devices Body Shells Prototyping Size: 245*188*34 mm

Material: abs

Weight: 353g

Process: Machining

Finish: Deburring, Painting

Lead time: 7 Days

Office Seats Handle Spare Parts Prototype Size: 320*68*14 mm Material: ABS Weight: 88g Process: Machining Finish: Deburring, Painting Lead time: 7 Days

Medical Devices Beds Parts Prototype Service Size: 540*320*43 mm

Material: Nylon

Weight: 1130g

Process: Machining

Finish: Deburring, Polish

Lead time: 10 Days

Body Case Rapid Prototype Service Size: 446*160*455 mm

Material: ABS

Weight: 2246g

Process: Machining, Vacuum

Finish: Power coating

Lead time: 10 Days

Prototypes of The Thermometer ABS Case Size: 164*20*14 mm Material: ABS, rubber Weight: 25g

Process: Machining, vacuum casting

Finish: Painting

Lead time: 7 Days

Scan QR to Read

Links:https://globefindpro.com/products/11721.html

Links:https://globefindpro.com/products/11721.html

Recommended Products

-

GQ50 Electric Concrete Rebar Cutting Machine

GQ50 Electric Concrete Rebar Cutting Machine

-

Tech-resources

Tech-resources

-

Rapid Prototyping

Rapid Prototyping

-

GQ40 Electric Concrete Rebar Cutting Machine

GQ40 Electric Concrete Rebar Cutting Machine

-

Marine Onshore and Offshore Cylinder

Marine Onshore and Offshore Cylinder

-

Hydraulic Presses Cylinder

Hydraulic Presses Cylinder

-

5 Axis CNC Machining Aluminum Precision Parts

5 Axis CNC Machining Aluminum Precision Parts

-

Tablet Packaging

Tablet Packaging

-

High Quality Custom 5 Axis Precision CNC Machined Aluminum Parts

High Quality Custom 5 Axis Precision CNC Machined Aluminum Parts

-

Excavator Cylinder

Excavator Cylinder

-

JBG-40B Rebar Threading Machine

JBG-40B Rebar Threading Machine

-

3-Side Seal Pouch Packaging

3-Side Seal Pouch Packaging

Hot Products