Rubber Tyre Injection Moulding Machine, ZH108R

Multi-station injection moulding machine for producing rubber tyres and rubber handrails  Specifications

Specifications

Optional

System flow chart Features No need for rubber mixing, direct injection molding of rubber particles; Rubber particles do not age for up to 6 months, and the products made of the rubber particles are wear-resistant and high-elastic; This injection moulding machine features large injection pressure and clamping force, which ensure the product is smooth and free of burrs; Standard industrial human-machine interface (HMI) and PLC control system are installed; This tyre injection moulding machine has a powerful vacuum system to remove the air in the mould cavity; Constant mold temperature control system is configured to ensure precise control of vulcanization speed; This rubber tyre injection moulding machine has a precise displacement control system to improve the working efficiency of the injector; Fully meet the demands of the vulcanization production of rubbers; Auxiliary Equipment

This injection moulding machine is suitable for processing rubber particles and then produce rubber products like low-speed tyres and rubber handrails.

| Stations | 8 | |

| Maximum injection volume | g | 3500 |

| Screw diameter | mm | 80 |

| Injection pressure | MPa | 100 |

| Clamping force | Ton | 500 |

| Mould space | mm | 850*850*300 |

| Die opening stroke | mm | 600 |

| Dimensions | mm | 13000*6000 |

| Heating power | kW | 30 |

| Total power | kW | 75 |

| Total weight | Ton | 100 |

Suction machine

Energy-saving hydraulic servo control system

System flow chart Features No need for rubber mixing, direct injection molding of rubber particles; Rubber particles do not age for up to 6 months, and the products made of the rubber particles are wear-resistant and high-elastic; This injection moulding machine features large injection pressure and clamping force, which ensure the product is smooth and free of burrs; Standard industrial human-machine interface (HMI) and PLC control system are installed; This tyre injection moulding machine has a powerful vacuum system to remove the air in the mould cavity; Constant mold temperature control system is configured to ensure precise control of vulcanization speed; This rubber tyre injection moulding machine has a precise displacement control system to improve the working efficiency of the injector; Fully meet the demands of the vulcanization production of rubbers; Auxiliary Equipment

Cooling tower cools down hydraulic oil and raw materials before they are fed into the injection moulding machine;

Air compressor can be connected to the injection moulding machine to ensure enough air supply;

Drying system helps avoid bubbles in finished rubber products;

Scan QR to Read

Links:https://globefindpro.com/products/1334.html

Links:https://globefindpro.com/products/1334.html

Recommended Products

-

SC-A132 LED Under Cabinet Light, 4W LED Surface Mount Downlight

SC-A132 LED Under Cabinet Light, 4W LED Surface Mount Downlight

-

SC-F117 COB LED Inground Light, 185mm 18W Outdoor Recessed LED Light

SC-F117 COB LED Inground Light, 185mm 18W Outdoor Recessed LED Light

-

SC-D105A Rigid LED Strip, DC 12V 2W LED Light Bar

SC-D105A Rigid LED Strip, DC 12V 2W LED Light Bar

-

Endoscope Zoom Coupler

Endoscope Zoom Coupler

-

SC-D102A Rigid LED Strip, Waterproof LED Light Bar

SC-D102A Rigid LED Strip, Waterproof LED Light Bar

-

Medical LED Cold Light Source Module

Medical LED Cold Light Source Module

-

Medical LED Cold Light Source, INP-LUM400

Medical LED Cold Light Source, INP-LUM400

-

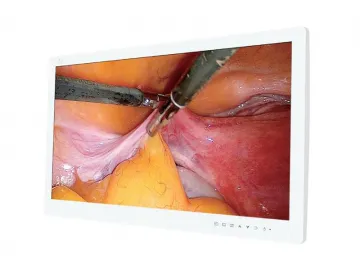

32 Inch Surgical Display Monitor

32 Inch Surgical Display Monitor

-

Endoscope Fixed Focal Coupler

Endoscope Fixed Focal Coupler

-

Alcohol Wipe Packaging Machine

Alcohol Wipe Packaging Machine

-

Alcohol Tissue Packaging Machine

Alcohol Tissue Packaging Machine

-

SC-B103 Ultra-thin LED Puck Light, RGB Dimmable LED, Waterproof Decking Light

SC-B103 Ultra-thin LED Puck Light, RGB Dimmable LED, Waterproof Decking Light