Aluminum Veneer

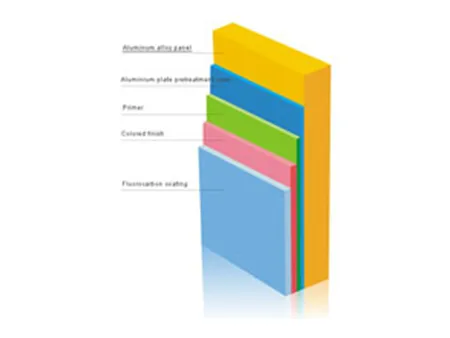

We primarily produce fluorocarbon coated aluminum veneers. Since there is PVDF contained in fluorocarbon coating material, our fluorocarbon coated aluminium veneer is also called PVDF coated aluminum veneer.

We know that the quality of exterior fluorocarbon coating is vital to the quality of aluminum veneer curtain walls, so we adopt superior quality fluorocarbon coating materials from world leading manufacturers. Our fluorocarbon coating suppliers include PPG, DNT, AKZO, and NIPPON, etc. and they can provide a wide range of coating colors to satisfy our different demands.

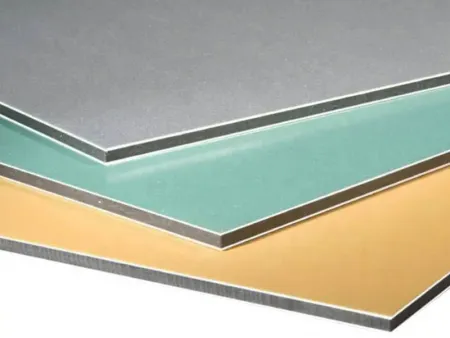

Our aluminum veneer is primarily composed of a faceplate, a reinforced structure, and suspension loops.

Standard veneer thickness: 2.0mm, 2.5mm, 3.0mm

Variety of colors are available.

Production flow chart of aluminum veneer

Aluminum veneers are usually chromized before they are fluorocarbon coated. The exterior fluorocarbon coating, which contains PVDF resin, features good corrosion resistance and weather resistance. Hence, our aluminum veneer has long service life and good resistance to acid rain, salt fog, strong UV, and extremely high or low temperatures, etc. Even used in harsh environment conditions, our aluminium veneer will not fade or effloresce easily.

Characteristics of our aluminum veneer

We adopt high quality aluminum alloy from internationally-leading manufacturers as the primary raw material. Hence, our aluminum veneers feature light weight, watertight, high rigidity, and high strength.

This type of incombustible aluminium plate also features good fire resistance.

Our aluminum veneers can be bended into an arc shape or any other shapes, with variety of colors coated on the surface. Thus, our aluminium veneer provides an ideal solution to create beautiful patterns on walls.

Aluminum veneers can also be used in combination with glass curtain walls, to make buildings more elegant and noble.

Due to its durability and dirt resistance, this type of aluminum plate is easy to clean and maintain. It is environmentally friendly.

Fluorocarbon coated

Porcelain fused

Marbleized

Marbleized

Wood grained

Applications of aluminum veneer

Our aluminum veneers, a kind of decorative building materials, are widely used for decorating both interior and exterior walls of various buildings, overhead walkways, elevators, and advertising boards.

Fluorocarbon coating standard

| Testing Item | Technical requirement | ||

| Physical dimension | Length and width | ≤2000mm, allowable deviation ±1.0mm | |

| >2000mm, allowable deviation ±1.5mm | |||

| Diagonal | ≤2000mm, allowable deviation ±3.0mm | ||

| >2000mm, allowable deviation ±3.0mm | |||

| Planeness | Allowable deviation ≤1.5mm/m | ||

| Average thickness of dried coating | Second layer coating ≥30μm Third layer caoting≥40μm Fourth layer coating ≥55μm | ||

| Fluorocarbon coating | Color difference | No visible chromatic aberration. Computerized color-difference meter should be adopted for inspecting single color coating. △E≤2NBS | |

| Glossiness | Tolerance of limit value ≤±5 | ||

| Pencil hardness | ≥±1H | ||

| Adhesive force | Cross cut test, 100/100, 0 level | ||

| Max. impact strength (Frontal impact) | 50kgf.cm (490N.cm), no crack, no paint stripping | ||

| Chemical resistance | Resistance to hydrochloric acid | To drop hydrochloric acid liquid on aluminum veneer surface for 15 minutes continuously, no bubbles produced. | |

| Resistance to nitric acid | Color difference △E≤5NBS | ||

| Resistance to motor | Make no difference within 24 hours | ||

| Resistance to detergent | No bubbles and no stripping within 72 hours | ||

| Corrosion resistance | Resistance to dampness | 4,000 hours above GB1740 level 2 | |

| Resistance to salt fog | 4,000 hours above GB1740 level 2 | ||

| Weather resistance | Fading | △E≤5NBS when our veneer has been used for 10 years | |

| Efflorescence | GB1766 class 1 when our veneer has been used for 10 years | ||

| Glossiness maintenance | ≥50% when our aluminium veneer has been used for 10 years | ||

| Thickness loss | ≤10% when our aluminum veneer has been used for 10 years | ||

(Aluminum panel coated by PVDF) solution list

| specification | coating layer | unit | material |

| 2.0(1.85mm) | ≥30um | M2 | 1100H24 |

| 2.5(2.35mm) | ≥30um | M2 | 1100H24 |

| 3.0(2.85mm) | ≥30um | M2 | 1100H24 |

The above price is subjected to Changjiang spot price of Aluminum.(Website for searching Changjiang spot price of Aluminum:www.smm.cn)

Coating layer≥40um : 0.7US/㎡,material3003H24: 1.4 US/㎡,material5002H24: 2.5 US/㎡,coated by PE:-2.8 US/㎡

Width≥1300mm: 1.4 US/㎡(exceeding 100mm each).

Bright color: 1.4 US/㎡

Jixiang Building Materials Corp. is a primary aluminum veneer manufacturer and supplier based in China. Since our inception, we have been committed to producing high quality building materials to both national and international customers. Depending on our advanced production technique, manufacturing equipment, and testing instruments, we can produce a variety of high quality construction materials, including aluminium veneers, aluminum honeycomb plates, aluminum composite panels, and aluminum coils, and more.

Due to our focus on quality control, our company has been ISO9001:2000 certified. Presently, our products are well accepted in Russia, Saudi Arabia, Iran, India, Singapore, and Indonesia, and more. If you need any of our construction materials, please contact us directly.

Links:https://globefindpro.com/products/15693.html

-

Aluminum Coil (Aluminum Sheet Coil)

Aluminum Coil (Aluminum Sheet Coil)

-

HDD Drill Pipe

HDD Drill Pipe

-

Quartz Glass Laser Flow Tubes/ Laser Cavity Filters/ Laser Reflectors

Quartz Glass Laser Flow Tubes/ Laser Cavity Filters/ Laser Reflectors

-

Directional Drilling Pilot

Directional Drilling Pilot

-

Aluminum Panel

Aluminum Panel

-

Brushed Finish Aluminium Composite Panel

Brushed Finish Aluminium Composite Panel

-

JL45D/60D Co-extrusion Zipper Extruder

JL45D/60D Co-extrusion Zipper Extruder

-

Fiber End Caps, Quartz End Caps

Fiber End Caps, Quartz End Caps

-

Fireproof Aluminum Composite Panel

Fireproof Aluminum Composite Panel

-

Why We Can Do

Why We Can Do

-

808nm Diode Laser Hair Removal Machine

808nm Diode Laser Hair Removal Machine

-

Rod Grease

Rod Grease