Pointed Bottom Bag Making Machine with Inline 2-Colors Printing XKJD-400

Paper Bag Machinery Manufacturer Request a quote Paper Bag Making Process

Material loading

Inline Printing

Side glue

Forming

Interrupt

Bottom glue

Bottom folding

Finished product

Specifications

Model: XKJD400 Paper bag length: 120-480mm(L) Paper bag width: 70-260mm(W) Paper thickness: 40-80g/㎡ Machine speed: 60-400pcs/min Paper roll width: 200-740mm Side gusset depth: 20-100mm Machine power: 7.5kW Machine weight: 1850kg Machine size: 4640x1470x1700mm Features The paper bag machine is specially designed for making pointed bottom paper bags with/ printed patterns. The paper bags are mostly used for packing food such as bread, pastries, treats. Paper bags with various specifications can be made by the bag making machine. Featuring high production efficiency, this paper bag making machine is an ideal choice for bag manufacturers. It’s integrated with many functions including hydraulically controlled roll loading, unwinding, web guiding system, tension control, inline printing, side gluing, photoelectric sensor. The paper bag making machine features a PLC control system with HMI touch screen for precise control, and a servo system for the control of paper bag length. The machine comes with constant tension control for unwinding, servo motor, variable frequency drive, inverter motor, etc. The paper bag machine will stop automatically when no material is fed to the machine. Designed with an enclosed automatic gluing and forming system; Side mounted work table makes it easy to operate. Details

2 Color inline printing PLC-based motion controller Inverter Low-voltage electrical products Web guiding system HMI touchscreen Servo motor Bag counting unit Tags: flat bottom paper bag making machine machines for french fries bag making paper bag printing machine paper bag bottoming machine

Material loading

Inline Printing

Side glue

Forming

Interrupt

Bottom glue

Bottom folding

Finished product

Specifications

Model: XKJD400 Paper bag length: 120-480mm(L) Paper bag width: 70-260mm(W) Paper thickness: 40-80g/㎡ Machine speed: 60-400pcs/min Paper roll width: 200-740mm Side gusset depth: 20-100mm Machine power: 7.5kW Machine weight: 1850kg Machine size: 4640x1470x1700mm Features The paper bag machine is specially designed for making pointed bottom paper bags with/ printed patterns. The paper bags are mostly used for packing food such as bread, pastries, treats. Paper bags with various specifications can be made by the bag making machine. Featuring high production efficiency, this paper bag making machine is an ideal choice for bag manufacturers. It’s integrated with many functions including hydraulically controlled roll loading, unwinding, web guiding system, tension control, inline printing, side gluing, photoelectric sensor. The paper bag making machine features a PLC control system with HMI touch screen for precise control, and a servo system for the control of paper bag length. The machine comes with constant tension control for unwinding, servo motor, variable frequency drive, inverter motor, etc. The paper bag machine will stop automatically when no material is fed to the machine. Designed with an enclosed automatic gluing and forming system; Side mounted work table makes it easy to operate. Details

2 Color inline printing PLC-based motion controller Inverter Low-voltage electrical products Web guiding system HMI touchscreen Servo motor Bag counting unit Tags: flat bottom paper bag making machine machines for french fries bag making paper bag printing machine paper bag bottoming machine

Scan QR to Read

Links:https://globefindpro.com/products/1625.html

Links:https://globefindpro.com/products/1625.html

Recommended Products

-

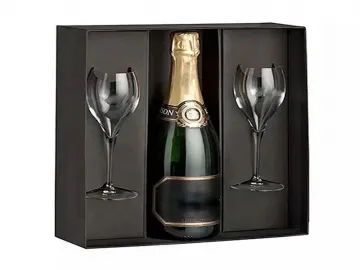

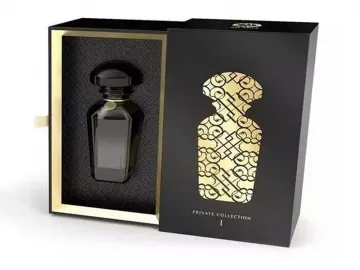

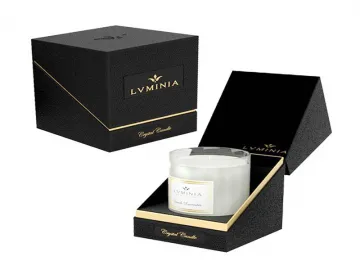

Top-Bottom Box, SP-31

Top-Bottom Box, SP-31

-

Foldable Paper Box, SP-30

Foldable Paper Box, SP-30

-

Aluminum Frame Glass Door with Pin Hinge

Aluminum Frame Glass Door with Pin Hinge

-

Plastic Squeeze Tube, SP-801

Plastic Squeeze Tube, SP-801

-

Paper Drawer Box, SP-28

Paper Drawer Box, SP-28

-

Large Aluminum Frame Glass Cabinet Door

Large Aluminum Frame Glass Cabinet Door

-

Metal Tin, SP-110

Metal Tin, SP-110

-

Paper Drawer Box, SP-27

Paper Drawer Box, SP-27

-

Aluminum Frame Glass Cabinet Door, Boloni 65

Aluminum Frame Glass Cabinet Door, Boloni 65

-

Cosmetic Tube, SP-802

Cosmetic Tube, SP-802

-

Top-Bottom Boxes

Top-Bottom Boxes

-

Top-Bottom Box, SP-32

Top-Bottom Box, SP-32

Hot Products