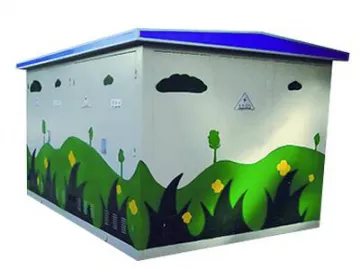

Pad-mounted Transformer

Pad-mounted transformers, also known as American substations, are an integrated power station that combines high-voltage control, protection, transformers and power distribution equipment according to specific wiring requirements. Transformer bodies, high load breaking switches and fuses are all set in fully sealed transformer oil tanks, and the transformer oil features an outstanding insulation performance and heat dissipation performance. Pad-mounted transformers feature a small size and light weight, as well as a safe, convenient installation and maintenance. They are widely used for outdoor power supply in cities, residential areas, hospitals, factories, mines, airports and railways.

Working conditions

Altitude: ≤1000m

Wind speed: ≤35m/S (≤700pa)

Ambient temperature: -35ºC - +40ºC

Relative humidity: daily average humidity≤95%, monthly average humidity≤95%

Quakeproof: horizontal acceleration≤0.4m/s2

vertical acceleration≤0.15mm/s2

Installation site slop: ≤3º

Installation site: the place without fire and explosion danger, serious pollution, chemical corrosion and strenuous vibration

Features

Small size and compact structure. The area covered is only 1/3 to 1/5 that of European substations of the same capacity.

Low noise and strong overload capacity S11 series transformers: The system includes high-voltage chambers, low voltage chambers, and transformers. The high voltage components feature fuse protection and are used for loop networks and terminals. Power supply methods are also flexible.

High-voltage chambers are equipped with oil humidity gauges, oil level gauges, pressure relief valves and oil discharging valves to monitor transformer operation states.

High voltage inlets use cable plugs and can be equipped with zinc oxide arresters. We will meet your needs for a variety of low voltage outputs and low voltage measurements, with shunt outlets added according to customer requirements.

The transformers utilize corrugated plates for heat dissipation. These plates are treated using a special technology for an exceptional corrosion resistance and a variety of shapes and structures. Common plates and stainless-steel plates can be chosen according to your needs.

Technical parameters

| Model | Rated capacity (KVA) | Voltage and tapping link rangeHigh voltage(KV) | Voltage and tapping link rangeTapping link range(%) | Voltage and tapping link rangeLow voltage(KV) | Connection and vector group | No-load losses(W) | Load losses(W) | No-load current(%) | Short circuit impedance(%) | Dimensions L×W×H (mm) |

| ZGS11-100 | 100 | 6 6.3 6.6 10 10.5 11 | ±5 ±2×2.5 | 0.4 | Yyn0 Dyn11 | 200 | 1580/1500 | 1.8 | 4 | 11830x1355x1735 |

| ZGS11-125 | 125 | 240 | 1890/1800 | 1.7 | 1830x1365x1735 | |||||

| ZGS11-160 | 160 | 270 | 2310/2200 | 1.6 | 1830x1375x1735 | |||||

| ZGS11-200 | 200 | 340 | 2730/2600 | 1.5 | 1830x1375x1735 | |||||

| ZGS11-250 | 250 | 400 | 3200/3050 | 1.4 | 1830x1405x1735 | |||||

| ZGS11-315 | 315 | 480 | 3830/3650 | 1.4 | 1830x1425x1735 | |||||

| ZGS11-400 | 400 | 570 | 4520/4300 | 1.3 | 1830x1435x1805 | |||||

| ZGS11-500 | 500 | 680 | 5410/5150 | 1.2 | 1830x1445x1860 | |||||

| ZGS11-630 | 630 | 810 | 6200 | 1.1 | 4.5 | 1830x1445x1860 | ||||

| ZGS11-800 | 800 | 980 | 7500 | 1 | 1830x1490x1860 | |||||

| ZGS11-1000 | 1000 | 1150 | 10300 | 1 | 1830x1675x2005 | |||||

| ZGS11-1250 | 1250 | 1360 | 12000 | 0.9 | 2100x1845x2035 | |||||

| ZGS11-1600 | 1600 | 1640 | 14500 | 0.8 | 2100x1885x2135 |

Scan QR to Read

Links:https://globefindpro.com/products/17335.html

Links:https://globefindpro.com/products/17335.html

Recommended Products

-

Oil Immersed Transformers, Series S11

Oil Immersed Transformers, Series S11

-

Cellophane Wrap

Cellophane Wrap

-

Dry Type Transformer, Cast Resin Dry Type Transformers

Dry Type Transformer, Cast Resin Dry Type Transformers

-

Custom Rewinding Service

Custom Rewinding Service

-

Healthcare Bracelet

Healthcare Bracelet

-

Prefabricated Substations

Prefabricated Substations

-

Secondary Switchgear, Series KYN28A-12

Secondary Switchgear, Series KYN28A-12

-

Kraft Paper

Kraft Paper

-

Newsprint Packing Paper

Newsprint Packing Paper

-

Paper Cutting Service

Paper Cutting Service

-

Oil Immersed Transformers

Oil Immersed Transformers

-

Translucent Paper

Translucent Paper