CNC machining Center, Vertical Machining 3-Axis

The CNC machine center can realize operations such as milling, boring, drilling and thread machining through different tools installed in the tool magazine. Our CNC machining center is equipped with ball guide way to ensure the stability and processing accuracy. And the processing procedure can be directly transmitted through RS232 port so that workers without machining experience can pick it up quickly. With a large size (1350mm*700mm) work table, the vertical machining center provided by us has a travel of 1200mm*600mm*650mm, which can significantly raise processing efficiency, shorten delivery time and reducing production cost. Should you have any problem, please don’t hesitate to contact us, our experienced team will offer you the most suitable solutions.

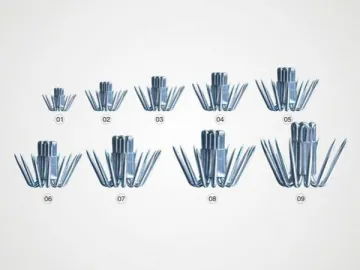

Sample

Parameters

| Model | Unit | JCVM6540 | JCVM8050 | JCVM1060 | JCVM1155 | JCVM1260 |

| Travel | ||||||

| X-axis travel | mm | 600 | 800 | 1000 | 1100 | 1200 |

| Y-axis travel | mm | 500 | 500 | 600 | 550 | 600 |

| Z-axis travel | mm | 450 | 500 | 600 | 550 | 650 |

| Worktable | ||||||

| Length | mm | 700 | 1000 | 1300 | 1200 | 1350 |

| Width | mm | 450 | 500 | 600 | 600 | 700 |

| Max. load on work table | Kg | 400 | 450 | 800 | 800 | 1000 |

| Spindle | ||||||

| Power | Kw | 5.5 | 7.5 | 11 | 11 | 15 |

| Spindle speed | rpm | 10000 | 10000 | 10000 | 10000 | 10000 |

| Spindle taper hole | BT40 | BT40 | BT40 | BT40 | BT50 | |

| Rapid traverse speed X/Y/Z | mm | 36/36/36 | 36/36/36 | 36/36/36 | 36/36/36 | 36/36/36 |

| Automatic tool changer (A.T.C) | ||||||

| Tool number/arm type tool magazine | PCS | 16 | 16/24 | 16/24 | 16/24 | 16/24 |

| Tool number /disc type tool magazine | PCS | 12 | 16 | 20/24 | 16/20 | 16/20 |

| Feed rate | ||||||

| Rapid traverse X/Y/Z | m/min | 30/30/24 | 36/36/36 | 36/36/36 | ||

| Max. cutting feed rate | m/min | 8 | 8 | 8 | 8 | 8 |

| Positioning accuracy | ||||||

| X/Y/Z-axis positioning accuracy | mm | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| X/Y/Z-axis repeatability accuracy | mm | ±0.005 | ±0.006 | ±0.005 | ±0.005 | ±0.005 |

| Machine information | ||||||

| Machine dimension(L*W*H) | mm | 2200*1900*2200 | 2700*2250*2700 | 3300*2250*2800 | 3500*2350*2800 | 3700*2500*3000 |

| Machine weight | Kg | 3500 | 5000 | 7000 | 8000 | 10000 |

| Power demand | Kw/A | 15/30 | 20/45 | 22/48 | 22/48 | 25/60 |

The CNC machining center has a completely enclosed structure with good protective performance.

Adopting ball screw of high rigidity, and direct connection with shaft coupling to ensure zero transmission clearance.

High-accuracy linear guide way of small friction coefficient is adopted to guarantee the machining accuracy.

The CNC systems from international famous brands like Siemens, Syntec and GSK are of high reliability and fast response speed.

The cooling tank is separated from this machine tool to facilitate the change of cooling liquid.

Regular lubricating oil supply to all transmission points can keep transmission fluency.

Equipped with air circulation equipment, the totally enclosed electric cabinet can guarantee dust prevention and cooling effect at the same time.

Standard Configuration

Mitsubishi M80 control system

Three axis linear guide

Automatic tool changer

Heat exchanger

Safe power supply system

Manual door

Optional Configuration

Automatic chip removal system

Electronic air conditioning

Voltage regulator

Air pressure maintaining device

Pneumatic safety door

The fourth axis

Links:https://globefindpro.com/products/17830.html