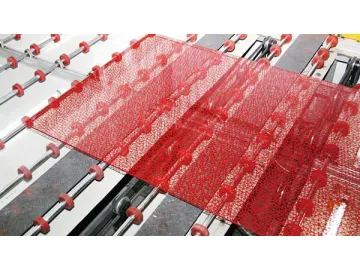

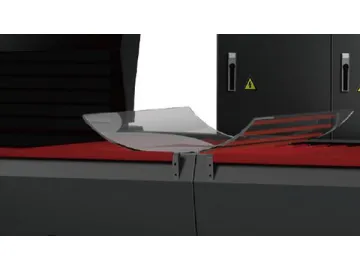

Automatic Glass Screen Printing Machine

Application:

It's suitable for screen printing architectural enameled glass.

| Model No. | NJ-GL2536SD | NJ-GL2545SD | NJ-GL2551SD | NJ-GL3060SD | NJ-GL3360SD |

| Max. printing size | 2500MM*3600MM | 2500MM*4500MM | 2500MM*5100MM | 3000MM*6000MM | 3300MM*6000MM |

| Min. printing size | 700MM*800MM | 800MM*800MM | 800MM*800MM | 900MM*1200MM | 1000MM*1000MM |

| Max. screen frame | 2900MM*4300MM | 2900MM*5200MM | 2900MM*5100MM | 3600MM*6780MM | 3900MM*6780MM |

| Substrate thickness | 3-19MM | 3-19MM | 3-19MM | 3-19MM | 3-19MM |

| Printing speed | 2PCS/MIN | 2PCS/MIN | 2PCS/MIN | 1PC/MIN | 1PC/MIN |

| Positioning accuracy | ≤±0.1MM | ≤±0.15MM | ≤±0.1MM | ≤±0.2MM | ≤±0.2MM |

| Power Supply | 380V,50HZ,12.7KW | 380V,50HZ,12.7KW | 380V,50HZ,16KW | 380V,50HZ,30KW | 380V,50HZ,30KW |

| Weight | 4000KG | 5000KG | 6000KG | 7000KG | 8000KG |

| Specifications | 12600MM*3700MM*1700MM | 15500MM*3700MM*1700MM | 17100MM*3700MM*1700MM | 19900MM*4300MM*1700MM | 19900MM*4700MM*1700MM |

Application:

It's suitable for screen printing color glittering glass.

| Model No. | JS-GL6580FM+3/4 | JS-GL8012FM+3/4 | JS-GL8016FM+3/4 | JS-GL8020FM+3/4 |

| Max. printing size | 650MM*800MM | 800MM*1200MM | 800MM*1200MM | 800MM*2000MM |

| Min. printing size | 300MM*300MM | 350MM*400MM | 350MM*400MM | 350MM*500MM |

| Max. screen frame | 2-12MM | 2-12MM | 2-12MM | 2-12MM |

| Printing speed | 5PCS/MIN | 5PCS/MIN | 5PCS/MIN | 4PCS/MIN |

| Positioning accuracy | ≤±0.1MM | ≤±0.1MM | ≤±0.1MM | ≤±0.1MM |

| Power supply | 380V,50HZ,3.2KW | 380V,50HZ,3.2KW | 380V,50HZ,4.2KW | 380V,50HZ,4.2KW |

Applications:

It's suitable for screen printing decorative shower room glass.

| Model No. | JS-GL1016SD | JS-GL1020SD | JS-GL1326SD | JS-GL1826SD | JS-GL2030SD |

| Max. printing size | 1000MM*1600MM | 1000MM*2000MM | 1300MM*2600MM | 1800MM*2600MM | 2000MM*3000MM |

| Min. printing size | 400MM*500MM | 400MM*600MM | 500MM*600MM | 400MM*600MM | 600MM*800MM |

| Max. screen frame | 3-19MM | 3-19MM | 3-19MM | 3-19MM | 3-19MM |

| Printing speed | 3PCS/MIN | 3PCS/MIN | 3PCS/MIN | 3PCS/MIN | 3PCS/MIN |

| Positioning accuracy | ≤±0.1MM | ≤±0.1MM | ≤±0.1MM | ≤±0.1MM | ≤±0.1MM |

| Power supply | 380V,50HZ,12.7KW | 380V,50HZ,12.7KW | 380V,50HZ,12.7KW | 380V,50HZ,12.7KW | 380V,50HZ,12.7KW |

Features:

1. Process: glass prepositioning→transport→precise positioning→printing→inspection→drying (automatic line)

2. New transport structure and precise positioning control, suitable for printing glass of different shapes.

3. Printing table is processed by special craft, so that glass is not scratched and rubbed.

4. Japanese Mitsubishi PLC control system, friendly touch screen HMI, malfunction display system and photoelectric protection device.

5. Horizontal or up/down movement of printing head is driven by worm gear motor and safety brake motor to realize stable frequency changing and steady lifting.

6. Frequency changing stepless scraping speed allows scraping and covering at different speeds.

7. Screen frame is adjusted by moving X. Y axis, which is convenient and precise.

8. Flooding bar can be set to pre-cover ink and cover ink during printing, so as to reduce screen block and shadow.

9. The scraping bar is equipped with constant pressure device, which can compensate automatically for substrate at different thickness after the scraping pressure is set.

10. Flooding bar is equipped with constant pressure device, which can compensate pressure automatically at will and handle ink at different thickness, so that there is no seismic wave caused.

11. The squeegee and flooding bar can be set for repeat movement without moving screen frame, which assures accuracy and no deformation.

Links:https://globefindpro.com/products/18893.html