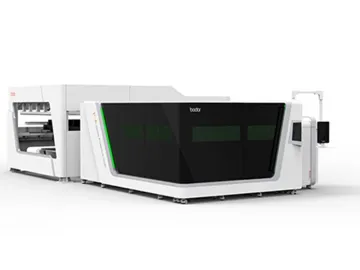

Full Covered Laser Cutting Machine with Automatic Loading System P-A

Sheet metal processing Aerospace Electronic product Auto parts Machinery Parts Household appliances Advertising Kitchenware Materials

Stainless steel Alloy steel Carbon steel Aluminum alloy Galvanized steel Copper Titanium Parameters

| Model | P3015A |

| Working area | 3000mm*1500mm |

| Laser output power | 6000w/4000w/3000w/2000w/1500w/1000w |

| X/Y-axis positioning accuracy | 0.03mm |

| X/Y-axis repositioning accuracy | 0.02mm |

| X/Y-axis max. speed | 140m/min |

Equipment Features

Cast iron bed

The bed of this machine is made from flake graphite cast iron with a tensile strength of 200MPa. The material is chosen because of its high compressive strength and hardness, ensuring excellent stability and wear resistance. The laser cutting machine will always maintain high precision.

Cast aluminum crossbeamThe crossbeam of the laser cutter is produced using lightweight and rigid aluminum. Each crossbeam is processed with integral steel mold pressure casting and will undergo artificial aging, solution treatment, and finishing to improve its rigidity, surface quality, and ductility. The crossbeam is perfect for adapting to the high speed movements during processing.

Automatic nozzle changerThe automatic nozzle changer features an accurate control system to replace nozzles according to different materials and thicknesses automatically, eliminating the need for time costly manual replacement. The system also enables automatic calibration and cleaning functions. The high-precision drive system provides reliable replacement precision and stability. The fully enclosed device maximizes operator safety.

Full protection coverThe laser cutting equipment is fully enclosed, preventing dust and eliminating light pollution during processing. Its intelligent monitoring system significantly reduces the failure rate, resulting in a safer, cleaner working environment.

Auto focus laser headOperated by the machine tool control system, the laser head can produce lasers with various focal lengths. When adjusted during the cutting process, the focal length of the laser can achieve different cutting effects. You will make adjustments based on material type and thickness. When switching to different materials, the auto focus laser head will read the system storage parameters to adjust to the proper focal length for the job.

The device comes with built-in double water cooling structures that regulate the temperature to protect the lenses from overheating. A collimation protective lens and focus protective lens are equipped to protect key components and maximize processing safety.

The size of your smart phone, this wireless remote can be used to operate this high precision equipment with just one hand. The remote is magnetic so simply fix it to the machine when not in use.

Bodor Pro2.0 operation systemThe operating system of the automatic laser cutter produces an intelligent layout for graphics cutting and supports the importing of multiple graphics, optimizing performance. The control system provides an intuitive operating experience, enhancing the utilization of the workpieces and ultimately reducing waste and saving money.

Exchange PlatformThe automatic exchange platform system enables rapid exchanging between the two exchange platform to significantly enhance the working efficiency of the laser cutter. The rack and pinion transmission system delivers improved rigidity and operating accuracy. This reduces feeding time and maximizes efficiency.

iLoader plus — Automatic loading and unloading systemLightweight design, intelligent and real time monitoring for safety。The vacuum suction cup holder made of aluminum alloy profiles is light in weight and high in strength; the overall design is lightweight. Increase the adsorption weight of the plate, support automatic loading and unloading of up to 25mm thick in a variety of breadths; The split frame design greatly reduces the installation time and saves transportation costs; The anti-adhesive edge-lifting function prevents sheet sticking and ensures single sheet feeding; Multiple sensing recognition to monitor whether the table is in place in whole process to ensure safe and stable operation;High wear-resistant anti-scratch belt prevents surface scratch. The height of the table is monitored in real time to ensure that the finished product is in the safe range during the processing cycle.

This allows operators to automatically monitor the operation range of the crossbeam and cutting parts. This greatly improves the equipment performance and safety of the users.

Auxiliary gas low pressure alarm functionThe system will sound an alarm if the pressure is lower than the optimal level for cutting and precision. This helps the operator to ensure cutting performance with greater accuracy through timely gas replacement.

Automatic lubrication systemThis system provides the necessary lubrication oil for the equipment at predetermined times and volumes to maintain high performance and safety. It will alarm if any abnormalities or low liquid levels are detected. The system greatly enhances cutting precision and maximizes the service life of the machine.

A new generation of safety guidance moduleThis device ensures the laser head maintains a safe distance from the workpiece to prevent collision. If contact is made, the machine will automatically stop to protect valuable components. The module minimizes the failure rate and improves cutting performance.

Intelligent alarm systemIn the case of any abnormality, the system will sound an alarm that will be displayed through the control center. This will help operators quickly find the cause of the problem and minimize downtime.

WIFI remote intelligent assistanceReal-time feedback anywhere, including fault analysis and troubleshooting operations.

Cutting Capacity Outline DimensionsLinks:https://globefindpro.com/products/20128.html

-

Precision Laser Cutting Machine i7

Precision Laser Cutting Machine i7

-

Car Polisher (Automatic Sanders with Dust Extraction System, Model V9)

Car Polisher (Automatic Sanders with Dust Extraction System, Model V9)

-

CO 2 Laser Cutter for Metal & non-metal Products BCL-BM

CO 2 Laser Cutter for Metal & non-metal Products BCL-BM

-

Lift Platform (Two Post Lift)

Lift Platform (Two Post Lift)

-

BCL-MU Mini Laser

BCL-MU Mini Laser

-

Car Polisher (Automatic Sanders with Dust Extraction System, Model V7)

Car Polisher (Automatic Sanders with Dust Extraction System, Model V7)

-

C Series Coil Fed Laser Cutter

C Series Coil Fed Laser Cutter

-

Laser Marking Metal and Plastics

Laser Marking Metal and Plastics

-

BML-FT Desktop Fiber Laser Marker

BML-FT Desktop Fiber Laser Marker

-

Tube and Sheet Laser Cutting Machine, F-T Series

Tube and Sheet Laser Cutting Machine, F-T Series

-

Acrylic Laser Cutting and Engraving

Acrylic Laser Cutting and Engraving

-

Our Work

Our Work