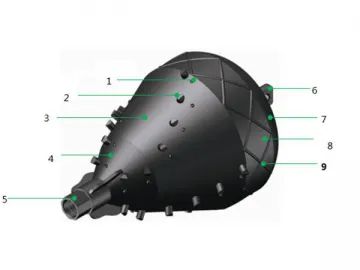

Expanding Hole Opener

1. Water nozzle

2. Metal pellets

3. Middle part

4. Front part

5. Shaft

6. Back handle

7. Rear head

8. Back part

9. Wear resistant area

| Model | D | L | N | W | f | H | φ | t | T-shaped structure | Kg |

| KTK60J-B70 | 300-600 | 166-480 | 60 | 110 | 48 | 30 | 32 | 70 | 50 × 5 | 55-125 |

| KTK73-B90 | 300-1000 | 70 | 110 | 55 | 40 | 42 | 90 | 65 × 5 | 60-308 | |

| KTK73L-B92 | 300-1000 | 70 | 110 | 55 | 40 | 42 | 92 | 72 × 5 | 60-308 |

Details of squeeze expanding reamer

Surface of reamer is designed to be smooth to reduce resistance;

High-strength steel plate is adopted for the curved head, with the wall thickness to be 12-18mm

The straight strip area of the reamer is welded to be wear resistant to extend the reamer's life;

Length of the wear resistant region is customizable;

The straight strip area will squeeze the wall to improve the wall's strength as the reamer rotates;

The reamer is formed from high-strength steel plate with a wall thickness of 12-18mm

The perfect combination of conical and the strip part helps to reduce resistance when the reamer works;

The conical body and the straight part are welded into a piece so the conical part will bear more load;

The high-strength wear resistant welded strip has largely extended the reamers' life

Cutters of the reamer are welded from high-strength alloy;

Each cutter is designed with a nozzle to cool them down and protect the cutters;

Users can apply nozzles with different diameter according to different construction conditions

The reamer and rod connector is connected with all-direction sleeve nut for easy assembly;

The coupling of all-direction sleeve nut and tubing joint is in line with API standards;

The external reinforcement and mandrel can bear the force;

For more details about fluted reamer please refer to:

Links:https://globefindpro.com/products/21263.html

-

Single Wall Drill Pipe

Single Wall Drill Pipe

-

600×600mm High Precision Camera Positioning Fiber Laser Cutter, CMA0606D-GV-B Laser Cutting System

600×600mm High Precision Camera Positioning Fiber Laser Cutter, CMA0606D-GV-B Laser Cutting System

-

Double Head 8 Position Bulb Fiber Laser Marking Machine, MF20-L-B Bulb Marking

Double Head 8 Position Bulb Fiber Laser Marking Machine, MF20-L-B Bulb Marking

-

Horizontal Directional Drill Rod and Bits

Horizontal Directional Drill Rod and Bits

-

30W CO2 Laser Marking Machine, MC30-E-A Laser Marker Equipment

30W CO2 Laser Marking Machine, MC30-E-A Laser Marker Equipment

-

20W Automated Assembly Line Fiber Laser Marking Machine, MF20-B-A Laser Marking System

20W Automated Assembly Line Fiber Laser Marking Machine, MF20-B-A Laser Marking System

-

30W Automated Assembly Line CO2 Laser Marking Machine, MC30-B-A Laser Marker Equipment

30W Automated Assembly Line CO2 Laser Marking Machine, MC30-B-A Laser Marker Equipment

-

1300×900mm Garment Template CO2 Laser Cutter, CMA1390-Y Laser Cutting Equipment

1300×900mm Garment Template CO2 Laser Cutter, CMA1390-Y Laser Cutting Equipment

-

Dual Wall Drill Pipe

Dual Wall Drill Pipe

-

Full Protection Multi-position Fiber Laser Marking Machine, MF20-E-B Full Protection Multi-position type Laser System

Full Protection Multi-position Fiber Laser Marking Machine, MF20-E-B Full Protection Multi-position type Laser System

-

1500×600mm Auto Feeding CO2 Laser Cutting Machine, CMA1606C-FET-FA Equipment

1500×600mm Auto Feeding CO2 Laser Cutting Machine, CMA1606C-FET-FA Equipment

-

600×600mm High Precision Fiber Laser Cutter, PFC0606L-A Laser Cutting System

600×600mm High Precision Fiber Laser Cutter, PFC0606L-A Laser Cutting System