EVA/TPT Backsheet Cutting and Layup Machine

Used for automatically cut and layup second EVA film and TPT backsheet in solar panel production line  Technical Parameters

Technical Parameters

Features

The standard hot melt function ensures that tailings will not fall off the machine;

Automatic correction, automatic detection of joints, automatic throwing and hole punching;

The hob cutting method prevents the material from be sticked onto the cutter to improve the cutter durability;

Hole punching tools can be customized according to customer requirements, such as types of flat hole, original hole and oval hole.

An EVA/TPT cutting & layup machine adopts high-precision and reliable cutting and layup technologies to provide efficient solar panel production solutions to meet customers’ high requirement.

| Item | Parameters |

| Panel size | (1,680-2,650)*(992-1,500)mm |

| Cycle time | 20s |

| Cutting accuracy | ±1.5mm |

| Laying accuracy | ±1.5mm |

| Overall dimensions (L*W*H) | 6,000*2,320*2,000mm |

| Voltage | AC 380V, 3 phase |

| Power | 5kW |

| Air pressure | 0.5-0.7MPa |

| Maximum material roll diameter | ≤800mm |

Features

The standard hot melt function ensures that tailings will not fall off the machine;

Automatic correction, automatic detection of joints, automatic throwing and hole punching;

The hob cutting method prevents the material from be sticked onto the cutter to improve the cutter durability;

Hole punching tools can be customized according to customer requirements, such as types of flat hole, original hole and oval hole.

Scan QR to Read

Links:https://globefindpro.com/products/221.html

Links:https://globefindpro.com/products/221.html

Recommended Products

-

Double Layer & Double Chamber Laminator

Double Layer & Double Chamber Laminator

-

Round Sealable Aluminum Foil Container

Round Sealable Aluminum Foil Container

-

MBB Cell Stringer Machine, MS40K

MBB Cell Stringer Machine, MS40K

-

Vertical Lift Cold Storage Door

Vertical Lift Cold Storage Door

-

Rapid Temperature Change Humidity Test Chamber

Rapid Temperature Change Humidity Test Chamber

-

Electric Sliding Cold Storage Door

Electric Sliding Cold Storage Door

-

Auto Labelling Machine

Auto Labelling Machine

-

Auto J-Box Soldering Machine

Auto J-Box Soldering Machine

-

Solar Panel Curing Line/Curing Room

Solar Panel Curing Line/Curing Room

-

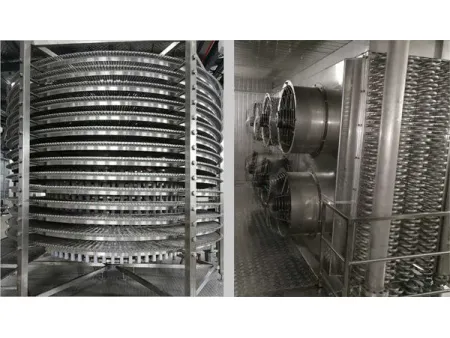

IQF Spiral Freezer

IQF Spiral Freezer

-

Round Smoothwall Aluminum Foil Container

Round Smoothwall Aluminum Foil Container

-

MBB Cell Stringer Machine, AM050F

MBB Cell Stringer Machine, AM050F