Aluminum Formwork Panel Manufacturing

The manufacturing process of our aluminum formwork products begins with high-quality raw materials and we have all of the necessary capabilities to meet your customization requests.

CuttingWe cut raw materials like alloy 6061-T6 into the required size.

PunchingThe worker is using a punching machine to cut holes in aluminum flat sheet-materials.

WeldingThe worker is welding the cut aluminum material into aluminum formwork. BiaoSheng adopts a semi-automatic welding method to better control the welding quality in this process.

Finished goodsThe weight of each aluminum formwork is about 10-22 kg, which is lighter than traditional steel structure formwork. It also has a large bearing capacity that is more than 60KN per square meter. All of this results in high cost performance.

BiaoSheng uses wood planks, stretch wraps and other materials to package finished goods, which can prevent the products from being damaged during transportation.

Links:https://globefindpro.com/products/22738.html

-

Wire Mesh, Wire Netting and Chain-Link Fencing

Wire Mesh, Wire Netting and Chain-Link Fencing

-

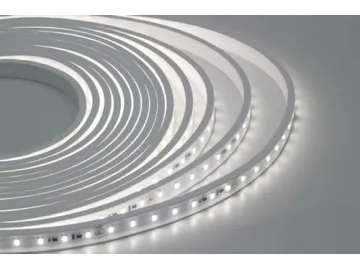

Indoor Sideview Warm White LED Strip, SMD 315 LED

Indoor Sideview Warm White LED Strip, SMD 315 LED

-

Aluminum Formwork System in Kenya

Aluminum Formwork System in Kenya

-

Wire Mesh, Wire Netting and Chain-Link Fencing

Wire Mesh, Wire Netting and Chain-Link Fencing

-

Farm Fence in America

Farm Fence in America

-

Non-waterproof IP20 SMD 2835 Digital IC Warm LED Strip Light

Non-waterproof IP20 SMD 2835 Digital IC Warm LED Strip Light

-

High-CRI 95 Non-Waterproof White LED Strip Light, 2835 SMD LED

High-CRI 95 Non-Waterproof White LED Strip Light, 2835 SMD LED

-

Wire Mesh, Wire Netting and Chain-Link Fencing

Wire Mesh, Wire Netting and Chain-Link Fencing

-

Custom Aluminum Formwork Panel

Custom Aluminum Formwork Panel

-

Long Run IP65 SMD2835 Warm LED Strip Light, 10m/20m/50m/100m

Long Run IP65 SMD2835 Warm LED Strip Light, 10m/20m/50m/100m

-

DC24V SMD 2110 White Warm LED Strip Light

DC24V SMD 2110 White Warm LED Strip Light

-

UV/Ultraviolet Black Light LED Flexible Strip Lights

UV/Ultraviolet Black Light LED Flexible Strip Lights