Custom Build Aluminum Formwork System

The aluminum panel formwork is an important component of an aluminum formwork system. It is traditionally made using special equipment after extrusion, and is capable of being assembled into mold frames of different sizes, which makes it ideal for a variety of construction projects. Each formwork weighs about 10 to 22kg, which is lighter than traditional steel formwork, and features a cost effective, outstanding bearing capacity of 60KN/m^2. Compared to steel and wood, aluminum has a higher recovery value.

| unit | Aluminum Concrete Form | Small metal form | Large metal form | |

| Reuse times | Times | ≥300 | 10-20 | 30-40 |

| Unit price (including all accessories) | USD/Sqm | 95-150 | 55 | 60 |

| Labor charge | 3.8-4.0 | 4.2 | 4.2 | |

| Auxiliary machinery cost | / | / | 1 | |

| Recovery value | 60-75 | 23 | 23 | |

| Weight | Kgs/Sqm | 10-22 | 35-40 | 80-85 |

| Bearing capacity | KN/Sqm | 60 | 30 | 60 |

| Thickness | mm | 4.0 | 2.3 | 5.0 |

| Application | Walls, roofs, posts, beams, bridges, stairs, etc. | roofs, posts, beams, bridges, etc. | walls | |

| Finished product | Textured walls and smooth surface | Rough surface | Textured walls |

Light weight and excellent corrosion resistance: The aluminum concrete form uses 6061-T6 alloy, with each form weighing about 10 to 22kg. It features an outstanding strength, excellent corrosion resistance, and excellent balanced weight.

Excellent reusability for a lower cost: under standard construction applications, the aluminum formwork can be reused more than 300 times, giving it a lower usage cost than traditional forms.

Excellent standardization and wide applicability: We offer multiple aluminum formwork types for different specification assemblies, according to project requirements.

Links:https://globefindpro.com/products/22754.html

-

Custom Build Aluminum Formwork System

Custom Build Aluminum Formwork System

-

Fence Manufacturing

Fence Manufacturing

-

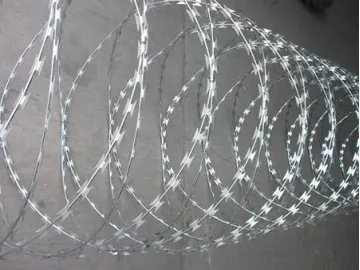

Wire Mesh, Wire Netting and Chain-Link Fencing

Wire Mesh, Wire Netting and Chain-Link Fencing

-

Wire Mesh, Wire Netting and Chain-Link Fencing

Wire Mesh, Wire Netting and Chain-Link Fencing

-

Wire Mesh, Wire Netting and Chain-Link Fencing

Wire Mesh, Wire Netting and Chain-Link Fencing

-

Fence Guard in Russia

Fence Guard in Russia

-

Wire Mesh, Wire Netting and Chain-Link Fencing

Wire Mesh, Wire Netting and Chain-Link Fencing

-

DC24V Non-Waterproof LED Strip Warm Light , 5050 SMD LED

DC24V Non-Waterproof LED Strip Warm Light , 5050 SMD LED

-

2835 SMD Warm White Waterproof IP65 LED Strip Light

2835 SMD Warm White Waterproof IP65 LED Strip Light

-

Aluminum Formwork in Brazil

Aluminum Formwork in Brazil

-

SMD5050 IP68 Waterproof Warm White LED Strip Lights

SMD5050 IP68 Waterproof Warm White LED Strip Lights

-

5050 SMD Waterproof IP62 Flexible LED Strip Warm Light

5050 SMD Waterproof IP62 Flexible LED Strip Warm Light