Crankshaft Detection

Testing process

1. Blank feeding testing.

2. First article testing of each process in processing

3. Cyclic testing for each process.

4. Finished products testing.

5. Shipment testing.

Content of testing:

ength testing----cylindrical testing----

----eccentricity testing----coaxiality testing

----distortion testing----parallelism testing

----verticality testing

Testing equipment

1. Blank feeding testing.

2. First article testing of each process in processing

3. Cyclic testing for each process.

4. Finished products testing.

5. Shipment testing.

Content of testing:

ength testing----cylindrical testing----

----eccentricity testing----coaxiality testing

----distortion testing----parallelism testing

----verticality testing

Testing equipment

Trilinear coordinates measuring instrument

measuring the size precision and location precision of crankshaft.

Contourgraph

measuring the R corner and roughness of the crankshaft.

Deflection instrument

measuring eccentric distance, parallel degree, torsion resistance, coaxial degree of crankshaft.

Hardness tester

measuring HB and HRC of crankshaft.

Projector

measuring the corner, roundness and size of crankshaft.

Metallograph

measuring the materials spheroidization rate

Flaw detector

detecting the surface crackle on the crankshaft.

Pneumatic instrument

measuring the size and roundness of the crankshaft outer circle

Scan QR to Read

Links:https://globefindpro.com/products/22989.html

Links:https://globefindpro.com/products/22989.html

Recommended Products

-

Manufacturing Equipment

Manufacturing Equipment

-

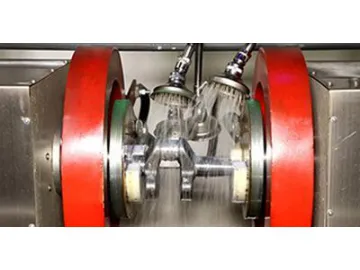

Deburring and Polishing

Deburring and Polishing

-

Constant Temperature Water Bath

Constant Temperature Water Bath

-

Crankshaft Oil Hole Drilling

Crankshaft Oil Hole Drilling

-

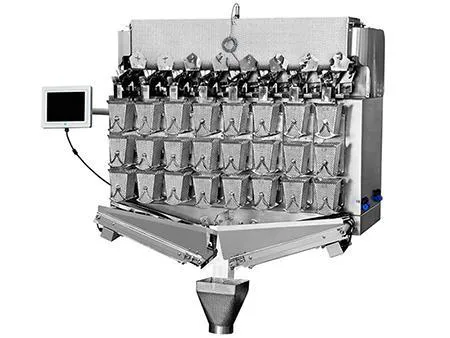

JW-A8 for Sticky Products (24 heads; 50-1000g; 1.5L)

JW-A8 for Sticky Products (24 heads; 50-1000g; 1.5L)

-

Digital Benchtop Centrifuge

Digital Benchtop Centrifuge

-

Main Journals Machining

Main Journals Machining

-

Electroplated Diamond Grooving Wheel for Drill Bits

Electroplated Diamond Grooving Wheel for Drill Bits

-

Crankshaft Crack Detection

Crankshaft Crack Detection

-

Custom Crankshaft

Custom Crankshaft

-

Laboratory Circulating Water Bath

Laboratory Circulating Water Bath

-

Air Compressor Crankshaft, America

Air Compressor Crankshaft, America

Hot Products