Reaction Injection Moulding

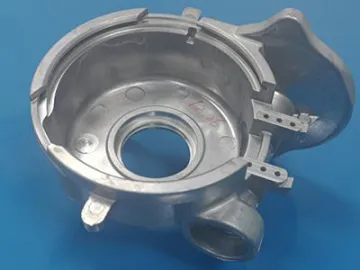

Reaction Injection Moulding (RIM) is the most advanced process for polyurethane parts moulding. Compared with Vacuum Casting Service, moulds are made by harder materials in RIM, which can replicates 200-1000 identical plastic products. Powered by professional reaction injection molding machines, HK Tenlita Technology Limited meets customer demand in small batch production.

Suitable conditions for RIM Production of plastic parts with simpler structure Production of components with larger size Prodcution of thick and uneven wall thickness products Applications of RIM

RIM shows its unique advantages in producing auto parts, medical equipment casings, toy products, digital products, home electronics, fitness equipment, etc.

Parameters| Applicable mould | ABS moulds (100 or more), resin moulds (1000 or more), Aluminum alloy moulds (1000 or more) |

| Casting material | Two component polyurethane |

| Materials used | HD-PU4210,DCP-RIM,AXSON-RIM 875 |

| Physical property | Similar to PP/ABS. The product has the characteristics of anti-aging, high impact resistance, high degree of fit, easy handling. |

| Injection pressure | About 10MPa |

| Flow control | 600g/s |

| Production speed | 15-30mins/unit |

| Standaed duplication accuracy | ±0.20mm |

| Max. Casting thickness | 30mm |

| Max. Casting workpiece | 2000mmX1200mmX1000mm,20KG |

Scan QR to Read

Links:https://globefindpro.com/products/24060.html

Links:https://globefindpro.com/products/24060.html

Recommended Products

-

Stereolithography (SLA)

Stereolithography (SLA)

-

Replaceable Tip Tweezers, ESD Anti-Static Industrial Tweezers

Replaceable Tip Tweezers, ESD Anti-Static Industrial Tweezers

-

ESD Safe Industrial Tweezers, Anti-Static Stainless Steel Tweezers

ESD Safe Industrial Tweezers, Anti-Static Stainless Steel Tweezers

-

Packaging Boxes and Wood Products Manufacturing

Packaging Boxes and Wood Products Manufacturing

-

Packaging Boxes and Wood Products Manufacturing

Packaging Boxes and Wood Products Manufacturing

-

Packaging Boxes and Wood Products Manufacturing

Packaging Boxes and Wood Products Manufacturing

-

Straight Point Tweezers

Straight Point Tweezers

-

3D Printing

3D Printing

-

Vacuum Casting Service for Silicone Seals

Vacuum Casting Service for Silicone Seals

-

5 Axis CNC Machining for Steering Knuckle

5 Axis CNC Machining for Steering Knuckle

-

Vacuum Casting

Vacuum Casting

-

Precision CNC Machining for Heavy Duty Medical Device

Precision CNC Machining for Heavy Duty Medical Device