Spray Bonding Nonwoven Production Line

Spray bonding nonwoven production line is used to produce high-elasticity spray bonded nonwoven, Primaloft One, etc. In the manufacturing process, spray bonded nonwoven drying oven is used for glue spraying, drying and making the raw material fixed. There are three layers in the spray bonded nonwoven drying oven, in which the raw materials are conveyed in “s” type. By this means, the raw materials could be sprayed and dried uniformly and the spray bonded cotton could obtain higher air permeability and higher elasticity. Sprayed bonded cotton is always used to produce clothes, embroidery, bedding, travel products, etc.

Specification: 1200mm

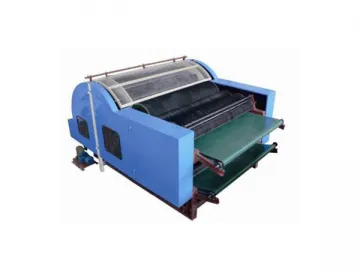

Pre-Opening machine Specification: 1200mm

Power: 9kw

Specification: 1200mm

Power: 7.5kw

Specification: 1300mm

Power: 7.5kw

Specification: 1800mm

Power: 4.5kw

Specification: 1850mm

Power: 15kw

Specification: 2500mm

Power: 4kw

Specification: 2500mm

Power: 70kw

Specification: 2500mm

Power: 4.5kw

Links:https://globefindpro.com/products/24334.html

-

Opening and Blending Machine for Cotton Blending and Cotton Cleaning

Opening and Blending Machine for Cotton Blending and Cotton Cleaning

-

Combined Opening and Blending Machine

Combined Opening and Blending Machine

-

Carding Machine for Fiber Disentangling (Double Cylinder Double Doffer)

Carding Machine for Fiber Disentangling (Double Cylinder Double Doffer)

-

Commercial Pool Heat Pump(Constant Temperature Controlled)

Commercial Pool Heat Pump(Constant Temperature Controlled)

-

Carding Machine for Coir Fiber Disentangling

Carding Machine for Coir Fiber Disentangling

-

Carding Machine for Coir Fiber Disentangling

Carding Machine for Coir Fiber Disentangling

-

Carding Machine for Fiber Disentangling (Single Cylinder Single Doffer)

Carding Machine for Fiber Disentangling (Single Cylinder Single Doffer)

-

HVAC Air Conditioner(Constant Air Temperature and Humidity Controlled)

HVAC Air Conditioner(Constant Air Temperature and Humidity Controlled)

-

Fiber Feeder (Spike Lattice Feeder)

Fiber Feeder (Spike Lattice Feeder)

-

Pool Heating, Air Cooling and Drying Multifunction Heat Pump

Pool Heating, Air Cooling and Drying Multifunction Heat Pump

-

Spray Bonding Oven

Spray Bonding Oven

-

Weighing Bale Opener

Weighing Bale Opener