CNC Machine Components

Tying CNC’s motor is paired well with the control system. With this excellent compatibility between the control system and the motor, a high precision is guaranteed.

Guideway Box guideway Roller linear guideway Ball linear guidewayTying CNC machines usually use a linear guideway. However, in order to achieve a higher cutting force, some machines will use a box guideway, which are stated in the machine. Linear guideways are available in a roller or ball option. For customers that need to machine precision parts, we recommend a ball linear guideway, whereas a roller linear guideway is better for processing large precision components.

Tying CNC’s spindle equipment includes a mechanical spindle and an electric spindle. Electric spindles are used in CNC drilling and milling machine due to their high speed.

According to the installation structure, spindles are categorized into direct drive, belt drive, and gear drive spindles.

A direct drive is used in a CNC drilling center. However, when the spindle bears a higher force, then a belt drive spindle is used to avoid damage to the spindle motor. A gantry milling machine uses a gear drive, which allows for a large torque and allows for the greatest machine depth.

Tool storage Turntable-type tool magazine Disc-type tool magazine Carousel-type tool magazine Chain-type tool magazineTying CNC provides four tool magazine types: carousel, turntable, disc and chain.

Carousel-type tool magazines are generally installed on CNC milling and drilling machine, which requires less tools. This particular tool magazine can hold 12 tools.

The Turntable type tool magazine is specially designed for vertical CNC machining centers. It equips the mechanical arm to prepare tools, which enhances the processing speed. This tool magazine can hold 24 tools.

The disc type tool magazine is mainly used in CNC drilling machines, and is capable of holding 16 tools at a time.

Links:https://globefindpro.com/products/24368.html

-

CNC Gantry Machining Center, Series LM-3025

CNC Gantry Machining Center, Series LM-3025

-

CNC Gantry Machining Center, Series LM-5029

CNC Gantry Machining Center, Series LM-5029

-

CNC Milling Machine

CNC Milling Machine

-

Residential Pool Heat Pump

Residential Pool Heat Pump

-

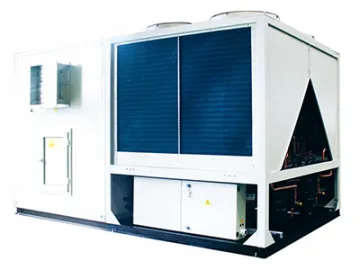

Fresh Air Ventilation Packaged Rooftop Unit

Fresh Air Ventilation Packaged Rooftop Unit

-

CNC Gantry Machining Center, Series LM-3017

CNC Gantry Machining Center, Series LM-3017

-

Direct Evaporative Air Conditioning

Direct Evaporative Air Conditioning

-

Air Source Heat Pump Hot Water Heater

Air Source Heat Pump Hot Water Heater

-

CNC Gantry Machining Center, Series LM-4227

CNC Gantry Machining Center, Series LM-4227

-

CNC Turning Center,CNC Lathe

CNC Turning Center,CNC Lathe

-

Exhaust Air Heat Recovery Fresh Air Machine

Exhaust Air Heat Recovery Fresh Air Machine

-

Home Air Conditioner

Home Air Conditioner