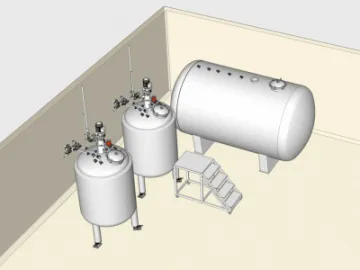

Cell Culture Bioreactor

The cell culture bioreactor is a multifunctional bioreactor, which is mainly used on the biopharmaceutical field, like the production of monoclonal antibody, insulin, albumin, vaccine, and blood products

Support processes including batch, fed-batch

Able to mix the hydrogen, carbon monoxide, nitrogen and methane together

With mixing, feed pump and foam breaker and other functions

Available with PLC system to monitor the pH, DO, backpressure, liquid level, temperature and other important parameters.

Details

Raw material

The material of cell culture bioreactor is autoclavable borosilicate glass or 316L stainless steel

Surface treatment

The interior of tank is electropolishing finish withRa≤0.28um while the outer surface is matt finish or brushed finish.

Magnetic fluid seal

Adopt advanced magnetic fluid seal technique and aerator with hollow shaft to prevent the powder caused by mechanical sealing.

Precise filters

The gas going in and out the cell culture tank all goes through the filter to avoid contamination caused by bacteria outside or inside.

Specifications

| Total amount | 2.5L | 5L | 7L | 14L | 30L | 40L | 75L | 150L | 300L |

| Mixing system | Off-line sterilization | In-line automatic sterilization | |||||||

| Mixing paddle | Stir up | Stir up/Stir down | |||||||

| Mixing control | 0-300rpm,±1rpm | ||||||||

| Ventilation mode | Central ventilation | Central ventilation/Side ventilation | |||||||

| Control system | Siemens S1200 | Siemens S1500 | |||||||

| IPC | 40 cm | 50 cm | |||||||

| Liquid level control | Conductivity electrode | Conductivity electrode /Weigh system | |||||||

| PH control | 2.00-14.00,±0.1pH | ||||||||

| DO control | 0-200%,±1% | ||||||||

| Back pressure control | Manual/Automatic | ||||||||

| Monitoring software | NetSCADA | ||||||||

| Database | Access/SQL | ||||||||

Scan QR to Read

Links:https://globefindpro.com/products/24574.html

Links:https://globefindpro.com/products/24574.html

Recommended Products

-

F02 Heat Transfer Vinyl Film

F02 Heat Transfer Vinyl Film

-

F01 Matt Heat Transfer Vinyl

F01 Matt Heat Transfer Vinyl

-

Caterpillar Hydraulic Filter

Caterpillar Hydraulic Filter

-

Ingersoll Rand Air Oil Separator

Ingersoll Rand Air Oil Separator

-

Cabin Air Filter

Cabin Air Filter

-

Daewoo Hydraulic Filter

Daewoo Hydraulic Filter

-

SL-4Y Sublimation Heat Transfer Vinyl

SL-4Y Sublimation Heat Transfer Vinyl

-

SL-6 Heat Press Transfer Film

SL-6 Heat Press Transfer Film

-

Pharmaceutical Wastewater Disinfection System

Pharmaceutical Wastewater Disinfection System

-

R1 Reflective Transfer Film

R1 Reflective Transfer Film

-

SL-4L Glossy Heat Transfer Film

SL-4L Glossy Heat Transfer Film

-

Air Oil Separator

Air Oil Separator