Sodium Carboxymethyl Cellulose (CMC) for Papermaking

Sodium Carboxymethyl Cellulose (CMC) for Papermaking  Paper Coating Improving Used to control and modify the rheology of paper coating and the dispersion of pigment, increasing the solids content of coating; Provide coating with pseudoplastic behavior, speeding up the coating process; Improve the water retention of coating, delivering superior control of water-soluble binder migration;

Paper Coating Improving Used to control and modify the rheology of paper coating and the dispersion of pigment, increasing the solids content of coating; Provide coating with pseudoplastic behavior, speeding up the coating process; Improve the water retention of coating, delivering superior control of water-soluble binder migration;

Excellent film forming ability helps improve coating gloss; Promote the performance of the whitening agent in the coating, improving the whiteness of the coated paper; Enhance the lubrication effect of coating, improving the coating quality while extending the service life of scraper blade; Pulp Strength Enhancing Add grinding efficiency of paper pulp, enabling pulp fibers to be refined while shortening pulping cycle; Make pulp fibers uniformly dispersed, improving paper machine runnability and resulting in better paper formation; Increase the retention rate of various additives, fillers and fibers; Increase bond strength between fibers, providing paper products with better physical strength properties; Work together with dry and wet strengthening agents to improve dry and wet strength of paper; Used as pulping sizing agent as gum rosin, AKD and other protective colloids, delivering better sizing effect; Surface Sizing Offer excellent rheology, leading to good film formation; Reduce the airborne porosity on paper surface, providing good resistance to oil and grease; Increase the gloss of paper; Improve paper sheet stability and surface smoothness, while preventing curling; Provide additional paper surface strength and abrasion resistance, reducing paper linting and dusting so that to improve printability and enhance the printing results; Specifications

Tags: paper coating consolidation

rheology modifier

paper strengthening agents

pulping additives

chemicals for paper making

paper bonding agent

Sodium carboxymethyl cellulose (CMC) is a natural anionic polymer for use in the pulp and paper industry to help increase paper quality characteristics, acting effectively to satisfy specific roles as follows.

Excellent film forming ability helps improve coating gloss; Promote the performance of the whitening agent in the coating, improving the whiteness of the coated paper; Enhance the lubrication effect of coating, improving the coating quality while extending the service life of scraper blade; Pulp Strength Enhancing Add grinding efficiency of paper pulp, enabling pulp fibers to be refined while shortening pulping cycle; Make pulp fibers uniformly dispersed, improving paper machine runnability and resulting in better paper formation; Increase the retention rate of various additives, fillers and fibers; Increase bond strength between fibers, providing paper products with better physical strength properties; Work together with dry and wet strengthening agents to improve dry and wet strength of paper; Used as pulping sizing agent as gum rosin, AKD and other protective colloids, delivering better sizing effect; Surface Sizing Offer excellent rheology, leading to good film formation; Reduce the airborne porosity on paper surface, providing good resistance to oil and grease; Increase the gloss of paper; Improve paper sheet stability and surface smoothness, while preventing curling; Provide additional paper surface strength and abrasion resistance, reducing paper linting and dusting so that to improve printability and enhance the printing results; Specifications

| Type | PL-5 | PL-10 | PL-30 | PL-50 | PL-200 | PL-600 | PM |

| 2% Soln. Viscosity (mPa·s) | 5-10 | 10-20 | 20-30 | 30-100 | 100-300 | 300-800 | 1000-3000 |

| (1#60R) | (2#60R) | (2#30R) | |||||

| Degree of Substitution | 0.65-0.85 | ||||||

| pH Value | 6.0-8.5 | ||||||

| Purity (%) | ≥98 | ||||||

| Loss on Drying (%) | ≤10.0 | ||||||

rheology modifier

paper strengthening agents

pulping additives

chemicals for paper making

paper bonding agent

Scan QR to Read

Links:https://globefindpro.com/products/2594.html

Links:https://globefindpro.com/products/2594.html

Recommended Products

-

Halogen-Free Intumescent Flame Retardant

Halogen-Free Intumescent Flame Retardant

-

CBFI-5 Ton Tube Ice Machine in Saipan, USA

CBFI-5 Ton Tube Ice Machine in Saipan, USA

-

Partially Hydrolyzed Polyacrylamide (PHPA)

Partially Hydrolyzed Polyacrylamide (PHPA)

-

EM64ZYC14 Parallel-shaft Gearmotor

EM64ZYC14 Parallel-shaft Gearmotor

-

Hydroxyethyl Cellulose (HEC) for Paint

Hydroxyethyl Cellulose (HEC) for Paint

-

Hydroxyethyl Cellulose (HEC) for Cosmetics

Hydroxyethyl Cellulose (HEC) for Cosmetics

-

Low Viscosity Polyanionic Cellulose (PAC LV)

Low Viscosity Polyanionic Cellulose (PAC LV)

-

3-in-1 Aluminum Foil/Cling Film/Silicone Paper Rewinder

3-in-1 Aluminum Foil/Cling Film/Silicone Paper Rewinder

-

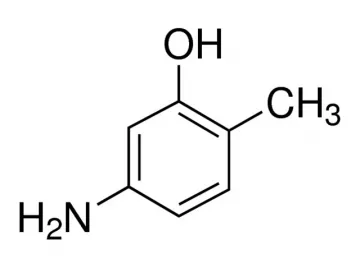

5-Amino-o-cresol

5-Amino-o-cresol

-

CBFI-12 ton Block Ice Plant in the Philippines

CBFI-12 ton Block Ice Plant in the Philippines

-

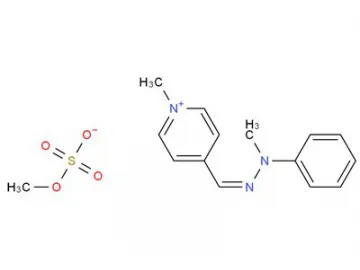

Basic Yellow 87

Basic Yellow 87

-

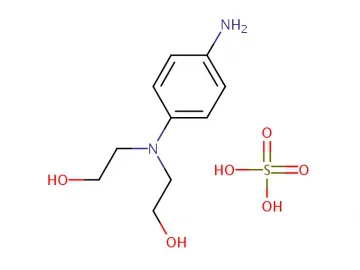

N,N-Bis(2-hydroxyethyl)-p-phenylenediamine sulphate

N,N-Bis(2-hydroxyethyl)-p-phenylenediamine sulphate

Hot Products