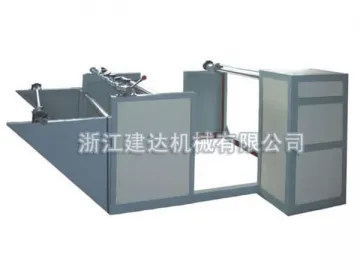

3-5 Layer Bubble Wrap Film Extrusion Machine

From the very beginning, since our foundation in 1983, we have been dedicated to making high quality products, including advanced air bubble film extrusion machines. Backed by our years of experience, we have become one of the most professional manufacturers in China, with a goal of offering our customers the best packing solutions.

This bubble wrap film extrusion machine is designed to produce polyethylene air bubble film (sheet) in 2 or 3 layers of air buddle film (bubble wrap). With the addition of an online lamination system, the amount of layers increases to 4 or 5. The finished product is widely used for household wares packing, post parcel packing, precise instruments packing, bicycle packing, furniture packing, and packaging for other fragile materials, as well as heat insulation applications.

The bubble wrap film extrusion machine consists of the main extruder, minor extruder, T-die, air bubble film formation roller, traction part and winding components.

Main technical data for reference| Model | JDFPE-1500 | JDFPE-2000 | JDFPE-2500 | JDFPE-3000 |

| Main screw diameter | Φ90mm | Φ90mm/Φ80mm | Φ90mm/Φ80mm | Φ105mm/Φ90mm |

| Minor screw diameter | Φ60mm | Φ70mm | Φ80mm | Φ90mm |

| Finished film width | 1500mm | 2000mm | 2500mm | 3000mm |

| Output | 90kg/h | 110kg/h | 150kg/h | 200kg/h |

| Main motor power | 30kw | 30kw/22kw | 37kw/30kw | 45kw/37kw |

| Minor motor power | 18.5kw | 22kw | 30kw | 37kw |

| Total power | 156kw | 225kw | 284kw | 340kw |

| Machine weight | 10000kg | 12000kg | 14000kg | 16000kg |

| Overall dimensions | 17m×5.5m×4.1m | 17m×6.0m×4.1m | 17m×6.5m×4.1m | 17m×7.0m×4.5m |

| Power supply | 380/3/4/50(Volt/Ph/Line/Hz) | |||

Highlight The film extrusion machine is equipped with all necessary hardware to create high quality material, and ensure the machine operates in a stable, strong manner. Machine software is PLC controlled, and with the addition of a touch screen, is easy to operate. Machine software is PLC controlled, and with the addition of a touch screen, is easy to operate. The T-die has an inner heating system, which saves electricity consumption The air bubble forming roller can produce air bubbles with different diameters to choose from.

Optional online perforation system Optional 4th layer lamination system Optional 5th layer lamination system Precise, optional automatic cutting & winding system

Finished product sample:

Finished product structure:

Two layer air bubble film Three layer air bubble film 4 layer air bubble film (with lamination of Aluminum film./PE film/Craft Paper) Five layer air bubble film (with lamination of Aluminum film./PE film/Craft Paper )

Finished product used for:

Furniture/instruments/machinery protection packing

Laminated with Aluminum film for insulation purposes

Post parcel/courier delivery bag

Links:https://globefindpro.com/products/26165.html

-

Single Layer Stretch Film Extruder

Single Layer Stretch Film Extruder

-

Film Grinder

Film Grinder

-

Three Layer Rotary Die Head Blow Film Machine

Three Layer Rotary Die Head Blow Film Machine

-

Plastic Thermoforming Machine

Plastic Thermoforming Machine

-

Quartz Apparatus / Wares

Quartz Apparatus / Wares

-

Material Distributor Machine in Air Bubble Film Production Line

Material Distributor Machine in Air Bubble Film Production Line

-

Quartz Plate / Optical Window

Quartz Plate / Optical Window

-

Electric Treadmill, Type HONE ONE-TOUCH

Electric Treadmill, Type HONE ONE-TOUCH

-

JDCPE-120/60*2-1000 Three Layer Stretch Film Co-Extruder

JDCPE-120/60*2-1000 Three Layer Stretch Film Co-Extruder

-

Compound PE Air Bubble Film Machine

Compound PE Air Bubble Film Machine

-

High Speed Plastic Sheet Extruder

High Speed Plastic Sheet Extruder

-

PE Blow Film Machine

PE Blow Film Machine