Flap Disc - Aluminum Oxide

Our flap disc (aluminum oxide) is often installed on angle grinders for a variety of applications, including rust removal on cast iron, welding joint polishing, burrs grinding of wood materials, stone grinding, and more.

Features1. The material of the plastic backing plate is polystyrene (PS), which features a high strength, a smooth grinding performance and economical costs.

2. The flaps on sanding discs are automatically overlapped by the machine. The workmanship is neat and smooth, so that there will be no broken flap during usage.

3. The flap can be widened and thickened. For example, for a 4-inch flap, the general number of flaps is 72, with the length of 22mm and the width of 14mm. When the customer requests the number of flaps to be added to 80, the length and width of the flap can also be increased, usually by 2-3mm. The abrasion resistance will also increase by 50%.

1. Shape:

T27 flap disc (flat, suitable for normal flat objects, such as straight steel plates);

T29 flap disc (depressed center, suitable for round or concave objects, such as stainless steel thermos)

2. Grit of abrasive cloth:

Can choose from: P36, P40, P60, P80, P100, P120, P150, P180, P240, P320, P400.

Coarse abrasive cloth (P36-P80, used for grinding, derusting and deburring rough workpieces);

Fine abrasive cloth (P100-P400, used for secondary polishing of workpieces).

3. Brand of abrasive cloth: Sanling, Kingcattle and GXK

Links:https://globefindpro.com/products/26331.html

-

4# Metal Zip Fastener (Open End Zip, Closed End Zip, Two Way Zipper)

4# Metal Zip Fastener (Open End Zip, Closed End Zip, Two Way Zipper)

-

5# Plastic Zipper, Closed End Zipper

5# Plastic Zipper, Closed End Zipper

-

Polishing Wheel (Non-woven Abrasive)

Polishing Wheel (Non-woven Abrasive)

-

4.5” Fiberglass Backing Flap Disc / 60 Grit T27 Flat

4.5” Fiberglass Backing Flap Disc / 60 Grit T27 Flat

-

Turbo Rim Chop Saw Wheel

Turbo Rim Chop Saw Wheel

-

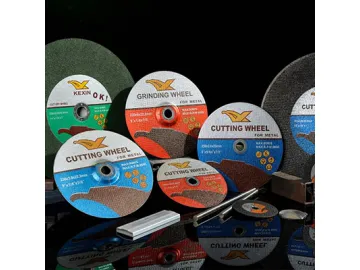

Cut Off Wheel

Cut Off Wheel

-

8# Metal Zipper (Copper Zip Fastener, Aluminum Zipper)

8# Metal Zipper (Copper Zip Fastener, Aluminum Zipper)

-

10# Metal Zipper (Colored Copper Zip, Aluminum Zipper)

10# Metal Zipper (Colored Copper Zip, Aluminum Zipper)

-

1# Metal Zip Fastener (Copper Zip, Closed End Zipper)

1# Metal Zip Fastener (Copper Zip, Closed End Zipper)

-

3# Plastic Zipper, Closed End Zip Fastener

3# Plastic Zipper, Closed End Zip Fastener

-

Segmented Chop Saw Wheel

Segmented Chop Saw Wheel

-

Metal Zippers

Metal Zippers