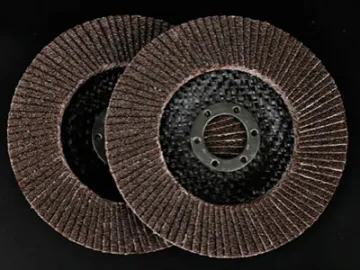

Deburring and Sanding Disc

Application

Our fiberglass backing flap disc is often used for welding seam polishing and deburring of metal, stainless steel and so on, and for polishing wood materials. Compared to plastic backing, the fiberglass backing flap disc is safer, making it ideal for use in high-strength industrial applications, such as metal manufacturing and construction industries.

1. We use high-strength fiberglass backing plate. The fiberglass mesh used is comprised of more than 5 layers, which makes it high temperature resistant and features an excellent safety.

2. Using a high-temperature calcined abrasive cloth, the sand is subjected to high-temperature calcination, thereby significantly improving the hardness and wear resistance of the sand. The sharpness and wear resistance are both increased by more than 30% when compared to traditional abrasive cloths.

3. The flaps on the sanding discs are automatically overlapped by the machine. The workmanship is neat and smooth, so that there will be no broken flaps during usage.

4. The flap can be widened and thickened. For example, for a 4-inch flap disc, the general number of flaps is 72, with the length of 22mm and the width of 14mm. When the customer requests the number of flaps to be added to 80, the length and width of the flap can also be increased, usually by 2-3mm. The abrasion resistance will also increase by 50%.

Custom deburring and sanding discs:1. Shape:

T27 flap disc (flat, suitable for normal flat objects);

T29 flap disc (depressed center, suitable for irregular surface objects)

2. Grit of abrasive cloth:

Can choose from: P36, P40, P60, P80, P100, P120, P150, P180, P240, P320, P400.

Coarse abrasive cloth (P36-P80, used for grinding, derusting and deburring rough workpieces);

Fine abrasive cloth (P100-P400, used for secondary polishing of workpieces).

3. Brand of abrasive cloth: Sanling,Kingcattle and GXK

Links:https://globefindpro.com/products/26359.html

-

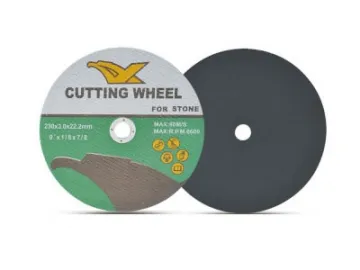

5” Ultra Thin Cut Off Wheel, T27

5” Ultra Thin Cut Off Wheel, T27

-

7” High Density Flap Disc / 240 Grit T27 Sanding Disc

7” High Density Flap Disc / 240 Grit T27 Sanding Disc

-

5” Zirconia Flap Disc / 100 Grit T27 Sanding Disc

5” Zirconia Flap Disc / 100 Grit T27 Sanding Disc

-

9” Cut Off Wheel, T27

9” Cut Off Wheel, T27

-

5” Alumina Flap Disc / 100 Grit T27 Sanding Disc

5” Alumina Flap Disc / 100 Grit T27 Sanding Disc

-

6” T27 Flap Disc / 120 Grit Sanding Disc

6” T27 Flap Disc / 120 Grit Sanding Disc

-

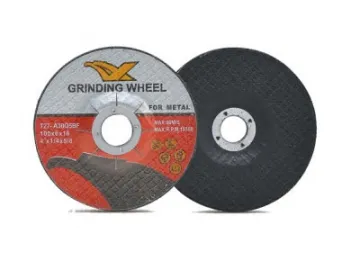

4” T29 Grinding Wheel

4” T29 Grinding Wheel

-

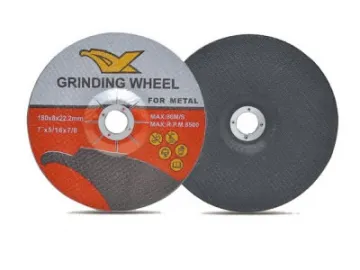

7” Surface Grinding Wheel, T29

7” Surface Grinding Wheel, T29

-

7” Cut Off Wheel, T27 Metal Cutting

7” Cut Off Wheel, T27 Metal Cutting

-

14” Cut Off Wheel, T27 Flat

14” Cut Off Wheel, T27 Flat

-

7” T27 Flap Disc / 40 Grit Sanding Disc

7” T27 Flap Disc / 40 Grit Sanding Disc

-

Continuous Rim Chop Saw Wheel

Continuous Rim Chop Saw Wheel