Asphalt Plant 120t/h, Item AMP1500-C 1500kg per batch mixing system

Asphalt Mixing Plant

Basic specifications

Maximum output: 120t/h

Mixing capacity: 1500kg/batch

Total installed capacity (excluding finished product bin): 330kw

Total floor area: 40x34=1360m2

Maximum fuel consumption: 6.2kg/t

Maximum dust emission concentration: 75 mg/Nm3

Finished product temperature: 130-160℃

Maximum ambient noise: 85dB(A)

Maximum ear noise: 70dB(A)

Dust removal mode: pulse bag filter

Fuel: diesel, heavy oil and gas

Optional accessories

The asphalt tank, finished product bin and powder bin can be mounted according to specific project needs.

Different fuel types can be chosen, including diesel, heavy oil and gas

An opening was designed on the mixing cylinder to prepare for adding more accessory equipment, such as PRD hot recycling equipment, SMA wood fiber adding device and more.

AMP1500-C stationary asphalt plant uses a special burner to work, thus giving it a high combustion efficiency and low fuel consumption. Light oil, heavy oil or gas can be used as fuel. The core parts of the equipment, such as the drying cylinder, mixing cylinder and vibrating screen, are all independently developed by our company. The equipment runs in a stable manner with a low failure rate, making it ideal for small and medium sized road construction and maintenance projects.

Our low energy consumption, low emission and high efficiency mixing equipment meets all energy consumption and environmental protection standards for various countries, including Ghana and Pakistan, two locations our customers have come from.

Basic specifications

Maximum output: 120t/h

Mixing capacity: 1500kg/batch

Total installed capacity (excluding finished product bin): 330kw

Total floor area: 40x34=1360m2

Maximum fuel consumption: 6.2kg/t

Maximum dust emission concentration: 75 mg/Nm3

Finished product temperature: 130-160℃

Maximum ambient noise: 85dB(A)

Maximum ear noise: 70dB(A)

Dust removal mode: pulse bag filter

Fuel: diesel, heavy oil and gas

Optional accessories

The asphalt tank, finished product bin and powder bin can be mounted according to specific project needs.

Different fuel types can be chosen, including diesel, heavy oil and gas

An opening was designed on the mixing cylinder to prepare for adding more accessory equipment, such as PRD hot recycling equipment, SMA wood fiber adding device and more.

Scan QR to Read

Links:https://globefindpro.com/products/26608.html

Links:https://globefindpro.com/products/26608.html

Recommended Products

-

Laying Nest

Laying Nest

-

Asphalt Plant 400t/h, Item AMP5000-C 5300kg per batch mixing system

Asphalt Plant 400t/h, Item AMP5000-C 5300kg per batch mixing system

-

High Volume Exhaust Fan, Model DJF(C) Axial Fan

High Volume Exhaust Fan, Model DJF(C) Axial Fan

-

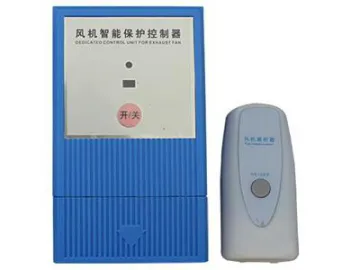

Two Stage Temperature Controller for Axial Fan

Two Stage Temperature Controller for Axial Fan

-

Portable Asphalt Plant

Portable Asphalt Plant

-

Fuel Burning Air Heating Blower

Fuel Burning Air Heating Blower

-

Axial Fan Protective Switch

Axial Fan Protective Switch

-

Stationary Asphalt Plant

Stationary Asphalt Plant

-

Asphalt Plant 160t/h, Item AMP2000-C 2300kg per batch mixing system

Asphalt Plant 160t/h, Item AMP2000-C 2300kg per batch mixing system

-

Gas Fired Air Heating Blower

Gas Fired Air Heating Blower

-

Shutter Exhaust Fan, Model DJF(T) Axial Fan

Shutter Exhaust Fan, Model DJF(T) Axial Fan

-

Winch, Pulley, Drinking and Feeding Line Parts

Winch, Pulley, Drinking and Feeding Line Parts