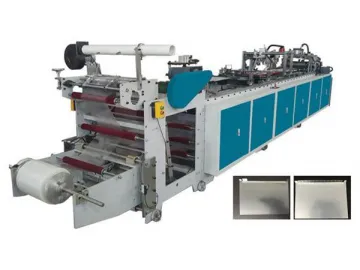

A4 Pocket Display Book Production Line

The A4 pocket display book production line is a double stack production line. The inner pockets can be divided into two stacks and welded on the cover sheets.

It is specially designed for data bags. All production processes, from raw material processing to final product completion, is completed in a fully automatic manner, which saves labor costs and simplifies the production processes.

Process display

Raw materials Pulling Automatic counting Spot welding Heat sealing Sheet conveying Inner and outer sheets combining Flipping Spine label paper placing Spine label welding Automatic counting conveying table Packaging Finished products

Spot welding

Sheet conveying

Flipping

Spine label paper placing

Spine label welding

Packaging

Finished products

Main advantages

The A4 pocket display book production line uses a double feeding system to feed without stopping the machine, thus improving production efficiency. It is equipped with a precise alarm function for no material and blocking conditions, making it easy for operators to feed materials quickly and easily, and handle any faults that might come up. This also improves production safety. The machine uses a special synchronous cutting and sealing action so that the data bags produced are the same size, and feature a neat, efficient seal. This also reduces waste to the lowest possible amount.

Technical parameters

| Model | SYS-CL620-A |

| Raw Material Thickness | Min 0.025mm |

| Product Size | A4 |

| Single Stack | 8-9 books/min |

| Double Stack | 16-18 books/min |

| Paper Type | A4 |

| Paper Size | 20/30/40/60 pcs display book |

| Gross Weight | 5600KG |

| Net Weight | 5400KG |

Scan QR to Read

Links:https://globefindpro.com/products/27114.html

Links:https://globefindpro.com/products/27114.html

Recommended Products

-

Edge Folding Machine for Expansion File Inner Page

Edge Folding Machine for Expansion File Inner Page

-

Stoneware Style Dinnerware

Stoneware Style Dinnerware

-

Blue Marble Style Dinnerware

Blue Marble Style Dinnerware

-

Kirigami Pattern Dinnerware

Kirigami Pattern Dinnerware

-

Galaxy Series Dinnerware

Galaxy Series Dinnerware

-

Fabric Style Dinnerware

Fabric Style Dinnerware

-

Plastic File Bag Making Machine

Plastic File Bag Making Machine

-

Plastic File Cover Welding Machine

Plastic File Cover Welding Machine

-

Box File Corner Protector Forming and Setting Machine

Box File Corner Protector Forming and Setting Machine

-

Round Bowl - Melamine

Round Bowl - Melamine

-

Cups & Mugs - Melamine

Cups & Mugs - Melamine

-

Islamic Art Series Dinnerware

Islamic Art Series Dinnerware

Hot Products