Base coating machine

Description

The DYC01 primer coating machine is suitable for the printing of aluminum, lead, tin and some other metal cans' circumferential surface in the form of background color rolled printing.

To make the surface of the aluminum can easier for printing patterns and add aesthetic sense to the printing, a layer of bottom ink is printed over the outer surface of the aluminum cans before printing patterns. The cylindrical shape is caught by the vacuum suction drum after passing the conveyor chain. The putt plugs the printing mandrel in the cylindrical shape. When the mandrel reaches the coating station with the aluminum cans, the aluminum cans touch the glue roll which is stick with the iron printing coating. The aluminum can moves against the glue roll and in the meantime, the iron printing coating is printed over the can body evenly by the PU glue roll to finish the grounding printing. Then the primer turntable with the mandrel which is bringing the aluminum cans with itself rotates to the unloading robot. The unloading robot takes off the aluminum can from the primer mandrel and send it to the transferring chain. The aluminum cans go into the primer drying oven along with the chain. After being dried by the primer drying oven, the aluminum cans are sent to the coating machine.

| Applicable can diameter | φ35-φ53mm |

| Maximum can length | 250mm |

| Maximum production speed | 120 /min |

| Motor power | 4.45kW/5.15kW |

| Dimensions | 2750*2330*1760mm |

| Net weight | 4500KG |

| Minimum intake pressure | 0.5MPa |

Links:https://globefindpro.com/products/27356.html

-

Extrusion Press machine

Extrusion Press machine

-

Necking machine

Necking machine

-

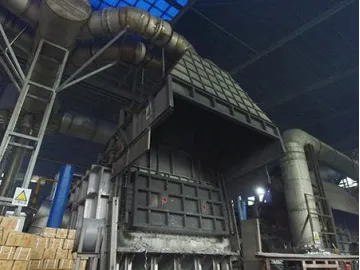

Melting Holding Furnace, using Heavy Oil Burner

Melting Holding Furnace, using Heavy Oil Burner

-

Charging Machine for Melting Holding Furnace

Charging Machine for Melting Holding Furnace

-

Holding Furnace, using Diesel Burner

Holding Furnace, using Diesel Burner

-

Tilting Melting and Holding Furnace

Tilting Melting and Holding Furnace

-

Extrusion Press machine

Extrusion Press machine

-

Double Sided Adhesive Tape

Double Sided Adhesive Tape

-

Aluminum Can Production Line

Aluminum Can Production Line

-

Plastic Caps

Plastic Caps

-

Offset printing machine

Offset printing machine

-

Accumulator

Accumulator