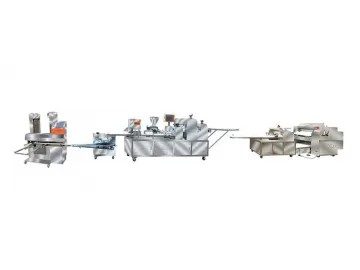

Two Roll Dough Sheeter

A two roll dough sheeter is used to re-press the pressed dough wrapper. The use of pressing technology gives the wrapper a glossier, brighter surface, without damaging the gluten. Using a dough wrapper rolling process, the finished products have a better layering effect. The dough slice thickness, shape and cutting size can all be easily adjusted, and the two roll dough sheeter matches other food machines to form processing lines such as bread machines, pastry machines, steamed bun machines and more.

| Overall size (L x W x H) | 4500x700x1500mm |

| Output | 1000-12000pcs/h |

| Equipment power | 2.8kw |

| Equipment weight | 450kg |

| Equipment voltage | 220/380V |

| Finished product weight | 10-300g/pc |

| Equipment frequency | 50HZ/60HZ |

Machine composition diagram

1. Electrical parts

OMRON photoelectricity

Japanese Mitsubishi PLC

Japanese IKO bearing

Mikipulley clutch

Delta inverter

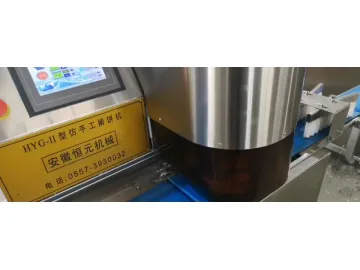

2. Control system

Touch screen + PLC intelligent control with memory preservation function: Operation is easy and fast. Customers can set multiple languages based on their needs.

Mitsubishi PLC

Delta touch screen

3. Machine frame

The entire machine frame features a seamless-edge winding technology with 304 stainless steel.

Features The main parts are all made of stainless steel, thus meeting food safety and hygiene standards.

This dough sheeter features digital control and a touch operation control panel. Operation is simple, and requires only a few minutes to familiarize yourself with.

With a high degree of automation and accurate quantification, all products are of a uniform size. The dough sheet thickness, shape, and cutting size are adjustable. This equipment can also be operated by just one or two people.

The dough sheeter does not require a large flour quantity, and is applicable in a variety of work spaces.

Links:https://globefindpro.com/products/28296.html

-

Stuffing Filling Machine

Stuffing Filling Machine

-

Automatic Dough Shaping Machine

Automatic Dough Shaping Machine

-

Steamed Bun Making Machine Line

Steamed Bun Making Machine Line

-

Nut Filling Automatic Encrusting Machine

Nut Filling Automatic Encrusting Machine

-

2-WF67K(Y) series CNC Control Bending Press Brake

2-WF67K(Y) series CNC Control Bending Press Brake

-

Three Roll Dough Sheeter

Three Roll Dough Sheeter

-

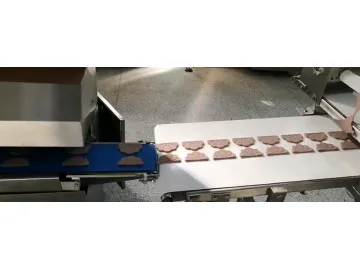

Automatic Baking Tray Arranging Machine, Type HYP-III

Automatic Baking Tray Arranging Machine, Type HYP-III

-

Automatic Cookie Making Machine

Automatic Cookie Making Machine

-

High Speed Backing Tray Arranging Machine

High Speed Backing Tray Arranging Machine

-

Dough Roller Machine

Dough Roller Machine

-

Bread and Hamburger Bun Making Machine

Bread and Hamburger Bun Making Machine

-

Solid and Liquid Filling Encrusting Machine

Solid and Liquid Filling Encrusting Machine