WD67K Electric-hydraulic Servo High Precision CNC Press Brake

Introduction  Technical Parameters

Technical Parameters

Machine main configuration

Precision quick clamp device Bosch Rexroth hydraulic system Oil pump Siemens motor

Linear guide rail, precision ball screw The high accurate linear encoder Fully automatic back gauge device Features The structure of the WD67K electric-hydraulic servo high precision CNC Press Brakeis integrally welded and processed, and the main parts of the machine are analyzed by ANSYS finite element analysis software, ensuring the machine tool is calibrated for optimal reliability and precision. The WD67K press brake adopts a numerical control system from Dutch DELEM, Italian ESA, or Swiss CYBELEC, which helps achieve the functions of bending angle graphics programming, angle correction compensation, bending pressure automatic calculation and automatic adjustment, automatically calculating the deformation compensation of the worktable, the length of the workpiece, bottom bending pressure, open height, back gauge automatic return, etc. The V-axis in the bed's compensation device is the numerical control axis which can control the crowning. By controlling the crowning, we can achieve deflection compensation. The crowning system is made up of a group of crowning wedges with an inclined plane, and the slope of the crowning wedge is designed according to the deflection curve which is analyzed by finite element analysis sliding and worktable vertical plate. According to the bending pressure to the workpiece, the numerical control system calculates the compensation required, automatically controls the relative displacement of crowning wedge block, effectively compensating the deflection slider and upper ram deformation, to achieve ideal bending on the workpiece.

The WD67K electric-hydraulic servo high precision CNC press brake is driven by a servo motor and is used to bend steel sheet into various shapes with outstanding precision and efficiency.

| Model | 63T/2500 | 80T/3200 | 100T/3200 | 160T/3200 | 200T/3200 |

| Nominal Force( KN) | 630 | 800 | 1000 | 1600 | 2000 |

| Bending Length (mm) | 2500 | 3200 | 3200 | 3200 | 3200 |

| Poles Distance( mm) | 1900 | 2700 | 2700 | 2700 | 2700 |

| Throat Depth (mm) | 350 | 350 | 400 | 400 | 400 |

| Slider Travel (mm) | 150 | 150 | 200 | 200 | 200 |

| working Height (mm) | 800 | 800 | 850 | 820 | 920 |

| Die Loading Height (mm) | 380 | 380 | 420 | 420 | 420 |

| Power (Kw) | 7.5 | 7.5 | 7.5 | 1.1 | 1.1 |

| Back Gauge×AxisStroke (mm) | 600 | 600 | 600 | 600 | 600 |

| Back Gauge×AxisSpeed (mm/s) | 100 | 100 | 100 | 100 | 100 |

| Dimension(LxWxH) (mm) | 3100x1450x2050 | 3500x1550x2100 | 3500x1580x2400 | 3500x1650x2500 | 3500x1680x2550 |

| Model | 400T/4000 | 500T/50000 | 500T/6000 | 500T/7000 |

| Nominal Force( KN) | 4000 | 5000 | 5000 | 5000 |

| Bending Length (mm) | 4000 | 5000 | 6000 | 7000 |

| Poles Distance( mm) | 3100 | 4000 | 4800 | 5400 |

| Throat Depth (mm) | 400 | 500 | 500 | 500 |

| Slider Travel (mm) | 200 | 300 | 300 | 300 |

| working Height (mm) | 800 | 800 | 800 | 800 |

| Die Loading Height (mm) | 420 | 600 | 600 | 600 |

| Power (Kw) | 30 | 37 | 37 | 37 |

| Back Gauge×AxisStroke (mm) | 800 | 800 | 800 | 800 |

| Back Gauge×AxisSpeed (mm/s) | 100 | 100 | 100 | 100 |

| Dimension(LxWxH) (mm) | 4300x2080x2730 | 5400x2525x4600 | 6500x2525x4200 | 7500x2525x4900 |

| Model | 800T/6000 | 800T/7000 | 800T/8000 | 1000T/6000 |

| Nominal Force( KN) | 8000 | 8000 | 8000 | 10000 |

| Bending Length (mm) | 6000 | 7000 | 8000 | 6000 |

| Poles Distance( mm) | 5000 | 5400 | 6400 | 4800 |

| Throat Depth (mm) | 600 | 600 | 600 | 600 |

| Slider Travel (mm) | 400 | 400 | 400 | 400 |

| Working Height | 800 | 800 | 800 | 800 |

| working Width | 400 | 400 | 400 | 500 |

| Die Loading Height (mm) | 800 | 800 | 800 | 800 |

| Power (Kw) | 2x30 | 2x30 | 2x30 | 2x37 |

| Back Gauge×AxisStroke (mm) | 800 | 800 | 800 | 800 |

| Back Gauge×AxisSpeed (mm/s) | 100 | 100 | 100 | 100 |

| Dimension(LxWxH) (mm) | 6500x2750x5300 | 7500x2750x5500 | 8500x2750x5900 | 6500x2800x5600 |

Machine main configuration

Precision quick clamp device Bosch Rexroth hydraulic system Oil pump Siemens motor

Linear guide rail, precision ball screw The high accurate linear encoder Fully automatic back gauge device Features The structure of the WD67K electric-hydraulic servo high precision CNC Press Brakeis integrally welded and processed, and the main parts of the machine are analyzed by ANSYS finite element analysis software, ensuring the machine tool is calibrated for optimal reliability and precision. The WD67K press brake adopts a numerical control system from Dutch DELEM, Italian ESA, or Swiss CYBELEC, which helps achieve the functions of bending angle graphics programming, angle correction compensation, bending pressure automatic calculation and automatic adjustment, automatically calculating the deformation compensation of the worktable, the length of the workpiece, bottom bending pressure, open height, back gauge automatic return, etc. The V-axis in the bed's compensation device is the numerical control axis which can control the crowning. By controlling the crowning, we can achieve deflection compensation. The crowning system is made up of a group of crowning wedges with an inclined plane, and the slope of the crowning wedge is designed according to the deflection curve which is analyzed by finite element analysis sliding and worktable vertical plate. According to the bending pressure to the workpiece, the numerical control system calculates the compensation required, automatically controls the relative displacement of crowning wedge block, effectively compensating the deflection slider and upper ram deformation, to achieve ideal bending on the workpiece.

Scan QR to Read

Links:https://globefindpro.com/products/28332.html

Links:https://globefindpro.com/products/28332.html

Recommended Products

-

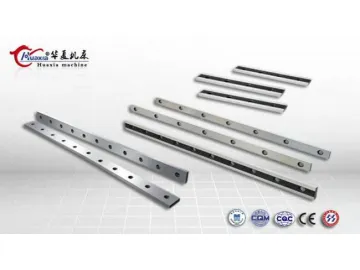

Shearing Machine Blade

Shearing Machine Blade

-

Q11 Mechanical Sheet Metal Shearing Machine

Q11 Mechanical Sheet Metal Shearing Machine

-

Hydraulic Door Skin Press Machine

Hydraulic Door Skin Press Machine

-

Plate Symmetric 3 Rolling Bending Machine

Plate Symmetric 3 Rolling Bending Machine

-

500W-12000W CNC Laser System Metal Cutting Machine

500W-12000W CNC Laser System Metal Cutting Machine

-

High Precision Metal Punch Press Machine

High Precision Metal Punch Press Machine

-

Sheet Metal Channel Bending Machine

Sheet Metal Channel Bending Machine

-

Multifunction Hydraulic Punching Notching Machine

Multifunction Hydraulic Punching Notching Machine

-

Hydraulic Punching Machine

Hydraulic Punching Machine

-

Upper Roller Universal Plate Bending Machine

Upper Roller Universal Plate Bending Machine

-

Open Type Power Press Machine

Open Type Power Press Machine

-

Pneumatic Punch Press Machine

Pneumatic Punch Press Machine