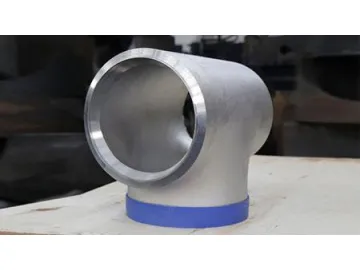

Stainless Steel Tee Pipe Fittings (Equal Tee, Reducer Tee)

Stainless steel tee pipe fittings are extensively applied in industries of petroleum, natural gas and electric power to connect three lengths of pipes for change of fluid flow direction in the run pipe. Our company provides both equal tees and reducer tees, which are all available with different specifications.

Common stainless steel features great resistance to corrosion, high temperature and acid, thus ensuring that our stainless steel tee is suitable for conveying varieties of corrosive fluid and also could work smoothly in circumstance with high temperature and high pressure.

Sample Exhibition 1. Large size stainless steel teeFor production of large size stainless steel tee, two steel plates are placed into corresponding mould for compression molding first by hydraulic press. Then butt welding will be done to attach these two steel pieces together. Through this exact process, the maximum caliber of the seamed stainless steel tee we could produce reaches 100 inches.

In our company, there are cold press forming machines exclusive for production of seamless tee made of stainless steel. In addition, we can also produce seamless tee with larger size by hot press forming by mould process for customers.

Seamless heavy thickness Equal Tee Seamless Equal Tee 3. Forged stainless steel teeThrough forging process, we are also able to manufacture stainless steel socket weld tee or threaded tee.

Forged SS Equal Tee Recommended Applications An extensive use of stainless steel fittings can be found in the following industries:

Petrochemical industry: Oil refining, ethylene, coal to oil, coal to olefins and other projects. Natural gas industry: LNG ships, LNG terminals, and natural gas pipeline projects. Power station industry: In thermal power plant, the water pipeline (usually stainless steel) used for supercritical units, circulating fluidized beds, power generation boilers, steam turbines, generators and other equipment, including reheater tube, superheater tube, water screen tube, economizer tube, downcomer and header, etc. Machinery and equipment manufacturing industry: Equipment structures such as pressure vessel, heat exchanger, fluid control, hydraulic transmission, instrumentation and others. Others: Shipbuilding, papermaking, desalination, food production and other industries; Aviation, aerospace, military, nuclear power plants and other projects. Custom Range

| Parameters | DN15-DN2500 (1/2"-100") |

| Wall thickness | Conventional wall thickness range: Sch 5s to Sch XXS Maximum wall thickness: 120mm |

| Standard | ASME B16.9, DIN2615, JIS B2312, JIS B2313, DIN2615, DIN EN10253, GB/T12459, GB/T13401, SH3408, SH3409, GOST17376, MSS-SP-75, and etc. |

stainless steel fittings, large diameter pipe fittings, seamless fittings, forged fittings

Links:https://globefindpro.com/products/29420.html

-

Carbon Steel Elbow Pipe Fittings (45° Elbow, 90° Elbow, 180° Elbow)

Carbon Steel Elbow Pipe Fittings (45° Elbow, 90° Elbow, 180° Elbow)

-

KBPC Bridge Rectifier

KBPC Bridge Rectifier

-

NS-5G/10G Roller Lever Micro Switch

NS-5G/10G Roller Lever Micro Switch

-

NL-5/10 Push Button Miniature Micro switch

NL-5/10 Push Button Miniature Micro switch

-

Stainless Steel Pipe Fittings

Stainless Steel Pipe Fittings

-

Stainless Steel Reducer Pipe Fittings (Concentric Reducer, Eccentric Reducer)

Stainless Steel Reducer Pipe Fittings (Concentric Reducer, Eccentric Reducer)

-

MDS 150A-250A Three Phase Diode Module

MDS 150A-250A Three Phase Diode Module

-

NL-5W/10W R-Shape Miniature Micro switch

NL-5W/10W R-Shape Miniature Micro switch

-

NNT4-4/38250P Three Phase Voltage Regulator

NNT4-4/38250P Three Phase Voltage Regulator

-

NNC69B-2Z Sealed Mini Electromagnetic Relay

NNC69B-2Z Sealed Mini Electromagnetic Relay

-

NV-16Z/21Z Short Lever Micro switch

NV-16Z/21Z Short Lever Micro switch

-

Carbon Steel Tee Pipe Fittings (Equal Tee, 45°Tee, Barred Tee)

Carbon Steel Tee Pipe Fittings (Equal Tee, 45°Tee, Barred Tee)