Ni80Cr20 High Resistance Alloy

Introduction:

Ni80Cr20 resistance alloy adopts nichrome alloy to have high resistivity, good oxidation resistance, excellent stability, a maximum operating temperature of 1200℃ and a service life longer than FeCrAl alloy.

| Style | Specification | ||

| Wire | Diameter: 0.03mm-8mm | ||

| Flat strip | Width: 0.4-40 | Thickness: 0.03-2.9mm | |

| Strip | Width: 8-250mm | Thickness: 0.1-3.0 | |

| Foil | Width: 6-120mm | Thickness: 0.003-0.1 | |

| Rod | Diameter: 8-100mm | Length: 50-1000 | |

Application

Ni80Cr20 resistance alloy can be widely used in household component, industrial furnace and various resistors, such as winding resistor, sheet metal resistor, air blower, electric melting furnace, smelting of iron, oven and even the electric cigarette.

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| ≤ | |||||||||

| 0.03 | 0.02 | 0.015 | 0.6 | 0.75~1.60 | 20.0~23.0 | Balance | ≤ 0.50 | ≤ 1.0 | - |

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation (%) | Density (g/cm3) | Resistivity (20℃) (Ω·mm2/m) | Heat conductivity (20℃) (W/(m·K)) | Average linear expansion coefficient (20℃-1000℃) (1/℃) | Specific heat capacity (20℃) (J/( kg℃)) | Melting point (℃) | Max. operating temperature (℃) | Magnetism |

| 420 | 810 | 30 | 8.4 | 1.09 | 15 | 18x10-6 | 0.46 | 1400 | 1200 | Non |

| 20℃ | 100℃ | 200℃ | 300℃ | 400℃ | 600℃ |

| 1 | 1.006 | 1.012 | 1.018 | 1.025 | 1.018 |

| 700℃ | 800℃ | 900℃ | 1000℃ | 1100℃ | 1300℃ |

| 1.01 | 1.008 | 1.01 | 1.014 | 1.021 | - |

Index

nickel chromium alloy, resistance wire, alloy strip, NiCr alloy

Scan QR to Read

Links:https://globefindpro.com/products/29995.html

Links:https://globefindpro.com/products/29995.html

Recommended Products

-

Cardboard Slitter Blades

Cardboard Slitter Blades

-

Ni35Cr20 High Resistance Alloy

Ni35Cr20 High Resistance Alloy

-

Thermocouple Alloy

Thermocouple Alloy

-

Female Slotter Blades

Female Slotter Blades

-

Tape Slitting Blade

Tape Slitting Blade

-

Special Shaped Blades & Machine Knives

Special Shaped Blades & Machine Knives

-

FeCrAl Alloy

FeCrAl Alloy

-

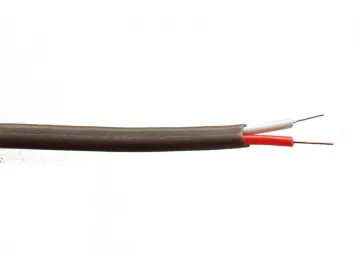

RTD Cable

RTD Cable

-

Male Slotter Blades & Machine Knives

Male Slotter Blades & Machine Knives

-

Press Brake Tooling

Press Brake Tooling

-

FeNi50 Thermal Expansion Alloy

FeNi50 Thermal Expansion Alloy

-

Thermocouple Compensating Cable

Thermocouple Compensating Cable

Hot Products