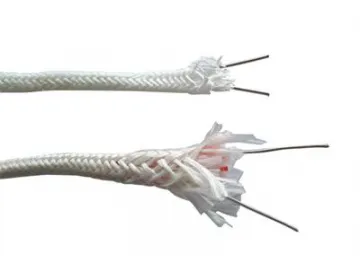

Thermal Spray Wire

Introduction

OHMALLOY adopts NiAl alloy solid-core wire of vacuum melting and casting control to make thermal spray wire, featuring with stable chemical composition, low oxygen content and high bond strength.

| Material | Main components | Features | Application | |

| HCF-50 | Ni, Cr, Ti | Bond strength≥48Mpa Hardness≥HRC46 Best performance of high temperature corrosion and oxidation resistance | Boiler water wall, anti corrosion and oxidation of the superheater, turbine blade, heat and corrosion resistance in steel mill. | |

| HCF-95 | Ni, Al, Ti | Bond strength≥75Mpa Strong oxidation resistance and corrosion resistance | High temperature base material | |

| HCF-25 | Ni, Cr, W, Mo | Bond strength≥45Mpa Hardness≥HRC33 Best performance of oxidation and corrosion resistance | Wear proof of four tubes in boiler, and resistance to wear and corrosion of shaft, pump, roller, dryer, etc. | |

| HCF-40 NiCrTiFe | Ni, Cr, W, Mo | Bond strength≥47Mpa Hardness≥HRC43 High performance of high temperature oxidation and corrosion resistance | Anti oxidation and corrosion in pressure vessel. | |

| HCF-80 CL-NiCr | Ni, Cr | Bond strength≥40Mpa Hardness≥HRC35 Good corrosion resistance | Anti-corrosion in water cooled wall, superheater and reheater | |

| HCF-01 | W, Al, Fe | Bond strength≥40Mpa Hardness≥HRC35 Certain performance of oxidation and corrosion resistance | Corrosion and oxidation resistance under lower temperature | |

| Monel | Ni, Cu | Resistance to hydrogen sulfide, sulfuric acid and hydrochloric acid | It is used in various containers of anti hydrogen sulfide and acid, and the repair of wear-proof parts. |

Application

Thermal spray wire is specially used in wire arc spraying bonding layer.

| Chemical composition | Coating bond strength (MPa) | Melting point (℃) | Coating hardness (HRC) |

| Ni95%Al5% | 65-68 | 1010 | 23-25 |

Index

NiAl alloy, alloy wire

Scan QR to Read

Links:https://globefindpro.com/products/30053.html

Links:https://globefindpro.com/products/30053.html

Recommended Products

-

Ball Shape Carbide Rotary Bur

Ball Shape Carbide Rotary Bur

-

Pointed Tree Shape Carbide Bur

Pointed Tree Shape Carbide Bur

-

Insulated Coating Resistance Wire

Insulated Coating Resistance Wire

-

Nanocrystalline Alloy

Nanocrystalline Alloy

-

Flame Shape Carbide Bur

Flame Shape Carbide Bur

-

CuNi10 Resistance Alloy

CuNi10 Resistance Alloy

-

90 Degree Cone Shape Carbide Bur

90 Degree Cone Shape Carbide Bur

-

CuNi44 Resistance Alloy

CuNi44 Resistance Alloy

-

Fiberglass Insulated Resistance Wire

Fiberglass Insulated Resistance Wire

-

CuMn12Ni4 Alloy

CuMn12Ni4 Alloy

-

Magnetic Alloy

Magnetic Alloy

-

Copper Manganese Alloy

Copper Manganese Alloy

Hot Products